Low-swinging carbon fiber composite core photoelectric composite overhead conductor

An overhead wire, photoelectric composite technology, applied in circuits, power cables, electrical components, etc., can solve the problems of inability to realize communication functions, poor wind resistance effect of wires, large galloping amplitude, etc., to reduce the galloping amplitude and tensile strength of transmission lines. The effect of increased strength and reduced lift coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

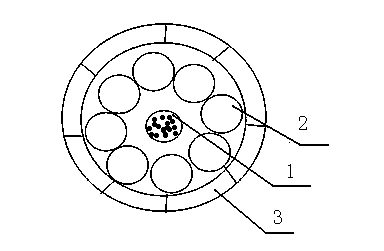

[0021] Such as figure 1 As shown, a low galloping carbon fiber composite core photoelectric composite overhead wire is characterized in that it includes a stainless steel light unit 1, a carbon fiber composite core 2, and a duralumin outer layer 3 from the inside to the outside; the carbon fiber composite core 2 is It is composed of epoxy resin, nano-expanded graphite with an expansion factor of more than 100 times, and reinforced carbon fiber. The reinforced carbon fiber is made of carbon fiber filaments, ceramic fiber filaments and glass fiber mats, which are cured and shaped by thermosetting resin. , the carbon fiber filament is a fiber filament made of polyacrylonitrile-based carbon fiber mixed with cellulose carbon fiber; a spiral surrounding stripe (not shown in the figure) is set on the outer contour of the duralumin-shaped wire outer layer 3 .

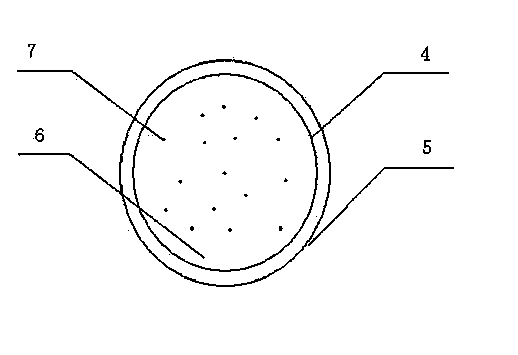

[0022] Such as figure 2 As shown, the stainless steel optical unit 1 is composed of several optical fibers 7 placed in a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com