Production method of selenium-rich germinated tartary buckwheat tea

A production method and technology for buckwheat tea, which are applied in the fields of food biology and functional food production, can solve the problem of not enriching selenium elements and the like, and achieve the effects of increasing absorbable selenium content, accelerating drying speed and shortening drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

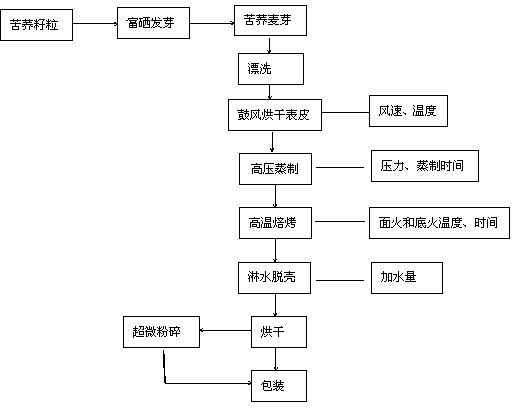

Method used

Image

Examples

Embodiment 1

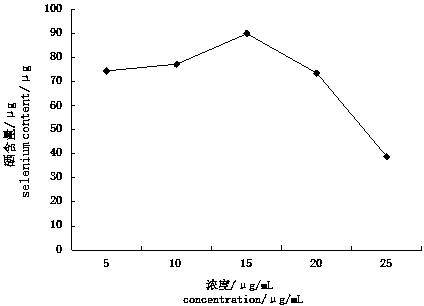

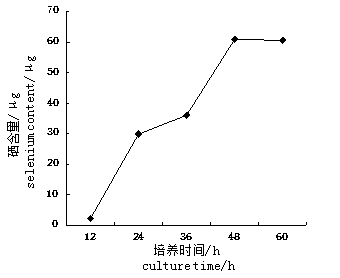

[0040] Embodiment 1: Selecting complete and plump grains. Disinfect with 1% sodium hypochlorite for 5 min. The sodium hypochlorite was rinsed with distilled water and soaked for 24 hours. The soaked buckwheat grains were added with 10% sodium selenite solution and incubated in a dark room at about 25°C for 1.5 days to obtain selenium-enriched germinated buckwheat. Rinse off the unabsorbed inorganic selenium on the surface of selenium-enriched germinated buckwheat, air-dry the buckwheat skin at 80 °C, steam at a pressure of 0.08 Mpa for 10 min, and bake the fully mature buckwheat grains at high temperature for 15 min, with a surface fire of 160 °C and a bottom fire of 130 °C. ℃. The buckwheat roasted at high temperature is quickly sprayed with cold water, and the surface of the buckwheat shell is evenly sprayed to shell. The buckwheat grains are dried in a blast drying oven, and then packaged as selenium-enriched germinated buckwheat tea.

Embodiment 2

[0041] Embodiment 2: tartary buckwheat, select complete and plump grains. Disinfect with 1% sodium hypochlorite for 5 min. Sodium hypochlorite was rinsed with distilled water, buckwheat grains were soaked in 10% inorganic selenium solution for 24 h, and cultured in a dark room at about 25°C for 2 days to obtain selenium-enriched germinated buckwheat. Rinse off the unabsorbed inorganic selenium on the surface of selenium-enriched germinated buckwheat, air-dry the buckwheat skin at 80 °C, steam at a pressure of 0.1 Mpa for 8 min, and bake the fully mature buckwheat grains at high temperature for 15 min, with a surface fire of 175 °C and a bottom fire of 120 °C. ℃. The temperature of the roasted buckwheat is about 60 ℃, and the surface of the buckwheat shell is sprayed with cold water to make it shell. The buckwheat grains are dried in a blast drying oven, and then packaged as selenium-enriched germinated buckwheat tea.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com