On-line dirt prevention and removing device adopting ultrasonic wave focusing

A focused ultrasonic, line anti-scaling and descaling technology, applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problem of electrode calibration and cleaning effects affecting test results, test electrode sensitivity and measurement Reduced accuracy, no built-in electrode cleaning equipment, etc., to meet the needs of complex production processes, good and effective cleaning effect, and realize the effect of industrial automation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but this does not constitute any limitation to the present invention.

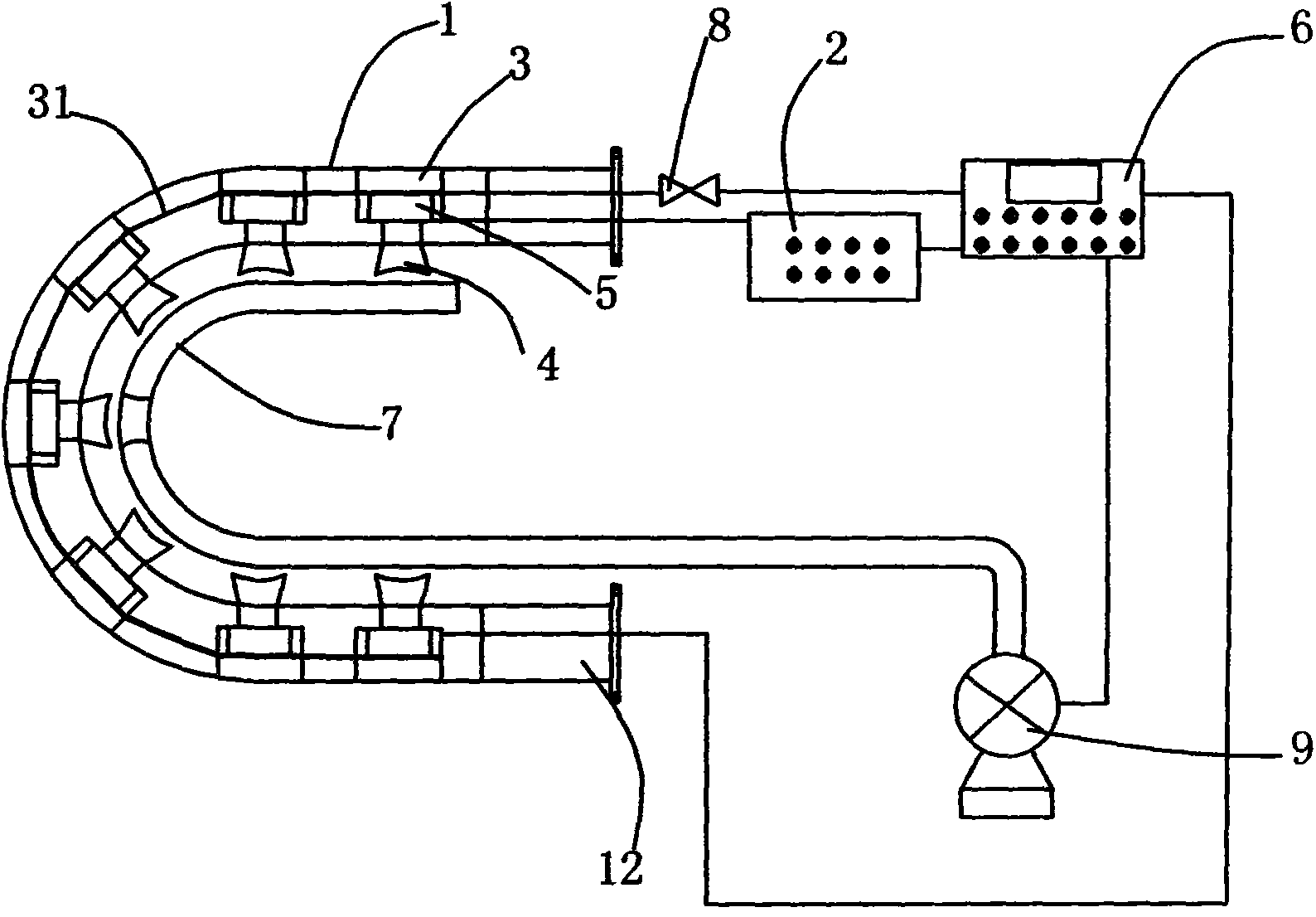

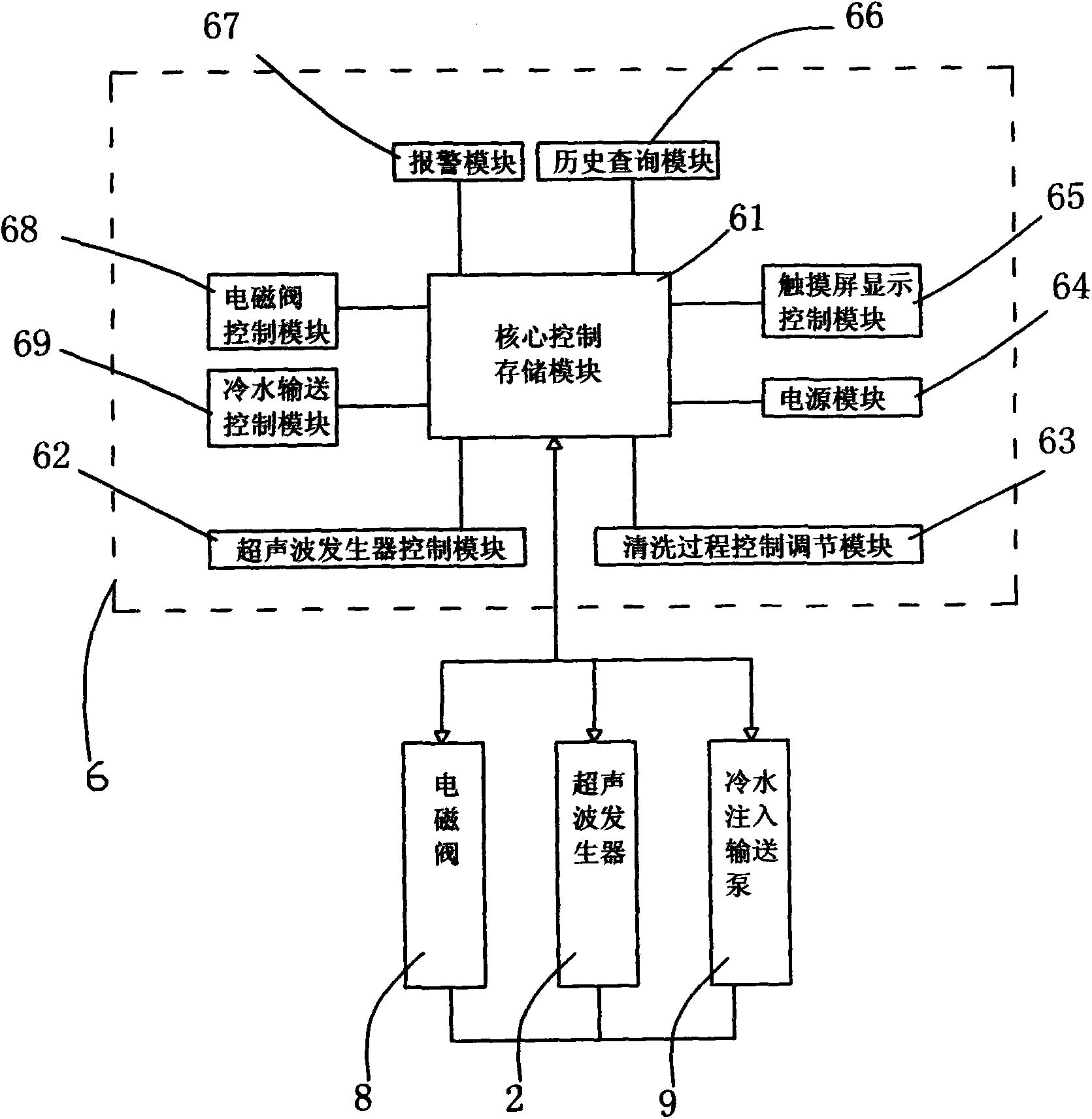

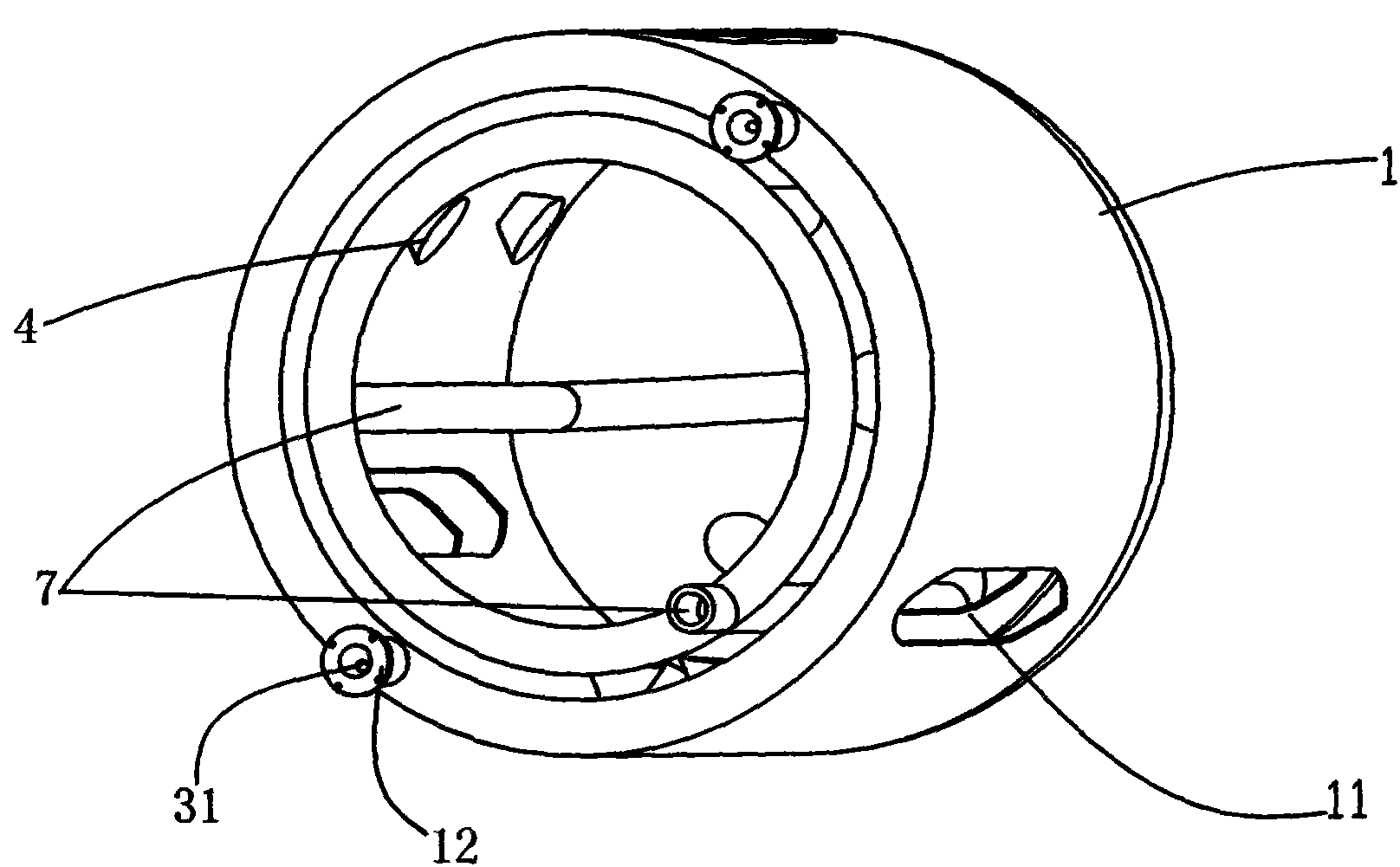

[0031] Such as figure 1 , 2 , 3, 4, 5, and 6 show:

[0032] A focused ultrasonic online anti-scaling and descaling device, comprising a housing 1 and an ultrasonic generator 2, characterized in that: the housing 1 is provided with a liquid flow channel 11, and the housing 1 is provided with a circulating cooling chamber 3, an amplification Rod 4, cold water delivery pipe 7, ultrasonic transducer 5 is arranged in circulating cooling chamber 3, and described ultrasonic generator 2 is connected with online cleaning controller 6 in addition and is connected with above-mentioned ultrasonic transducer 5, and described amplifying bar 4 is an inverted trapezoidal structure with a concave top, which is arranged in a semicircular focus on the inner side of the housing 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com