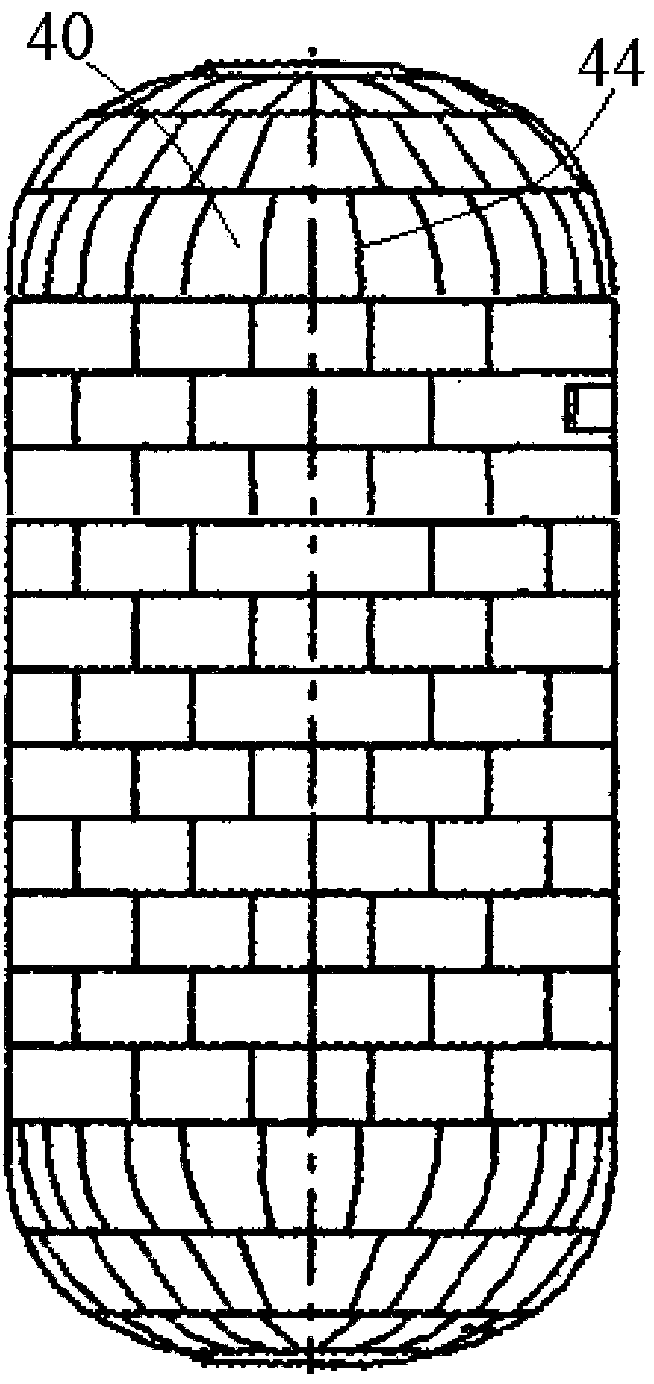

Narrow gap groove of steel containment vessel of nuclear power station and automatic welding method thereof

A steel containment, automatic welding technology, applied in nuclear power generation, welding equipment, arc welding equipment and other directions, can solve the problems of large consumption of welding materials, long welding cycle, large welding workload, etc., to improve welding efficiency, The effect of shortening welding cycle and reducing welding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

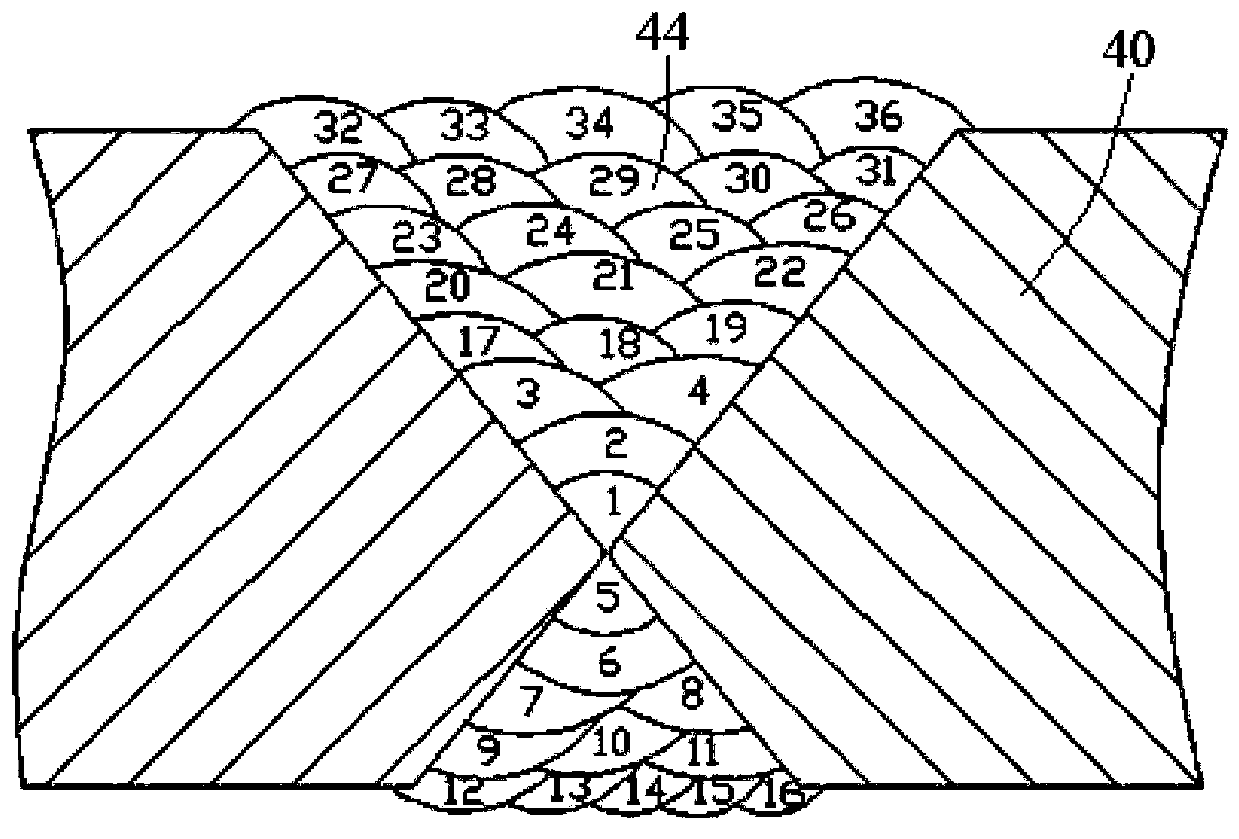

[0023] In order to make the purpose of the invention, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

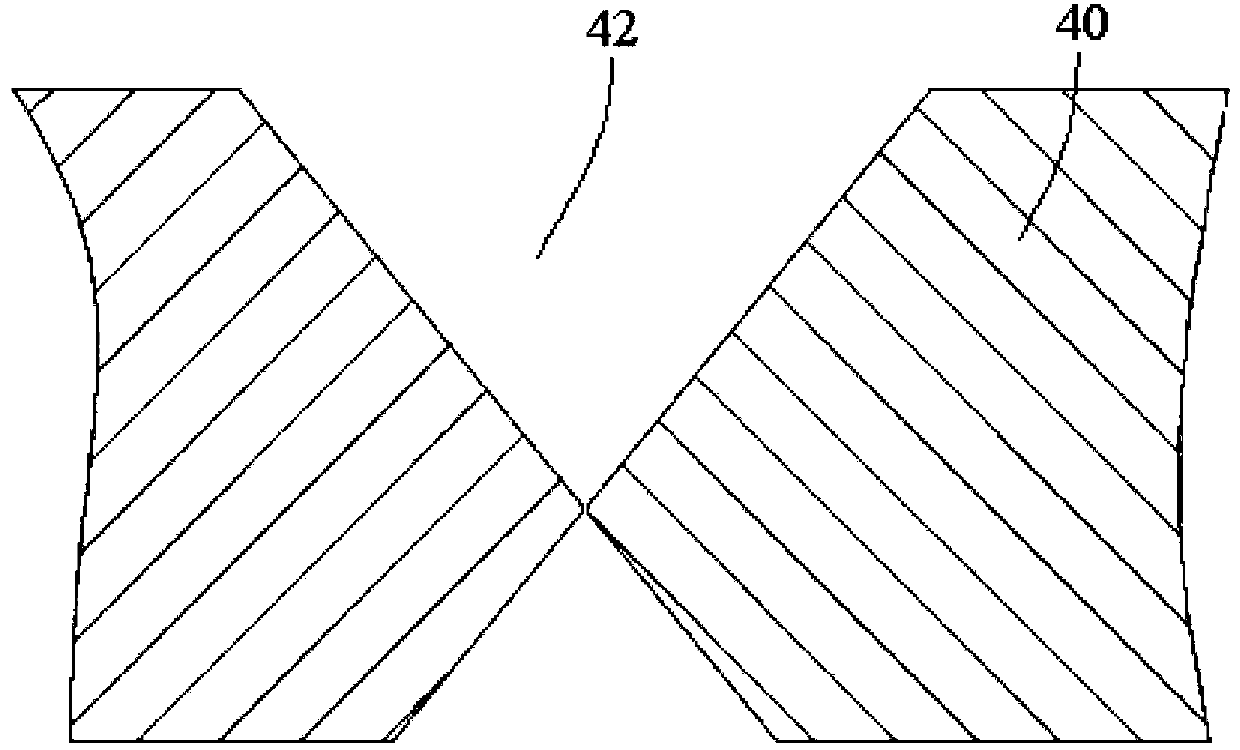

[0024] In order to improve welding efficiency and weld seam quality, the present invention uses pulsed MAG (melting electrode gas shielded arc welding) to weld the steel containment of nuclear power plants. MAG is currently one of the most advanced welding methods in MIGA welding in the world. When it is working, it uses argon, helium and other inert gases as shielding gas, and the welding wire is fed by the automatic wire feeding mechanism. The parameters of automatic walking welding. Compared with TIG (Tungsten Inert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com