Apparatus used for preparing aqueous nitric acid solution

A nitric acid aqueous solution, nitric acid technology, applied in the direction of nitric acid, nitrogen oxides/oxyacids, etc., can solve the problems of difficulty in recycling, acid mist pollution, large reaction range, etc., and achieves reduction in production, good environmental protection, and reaction. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

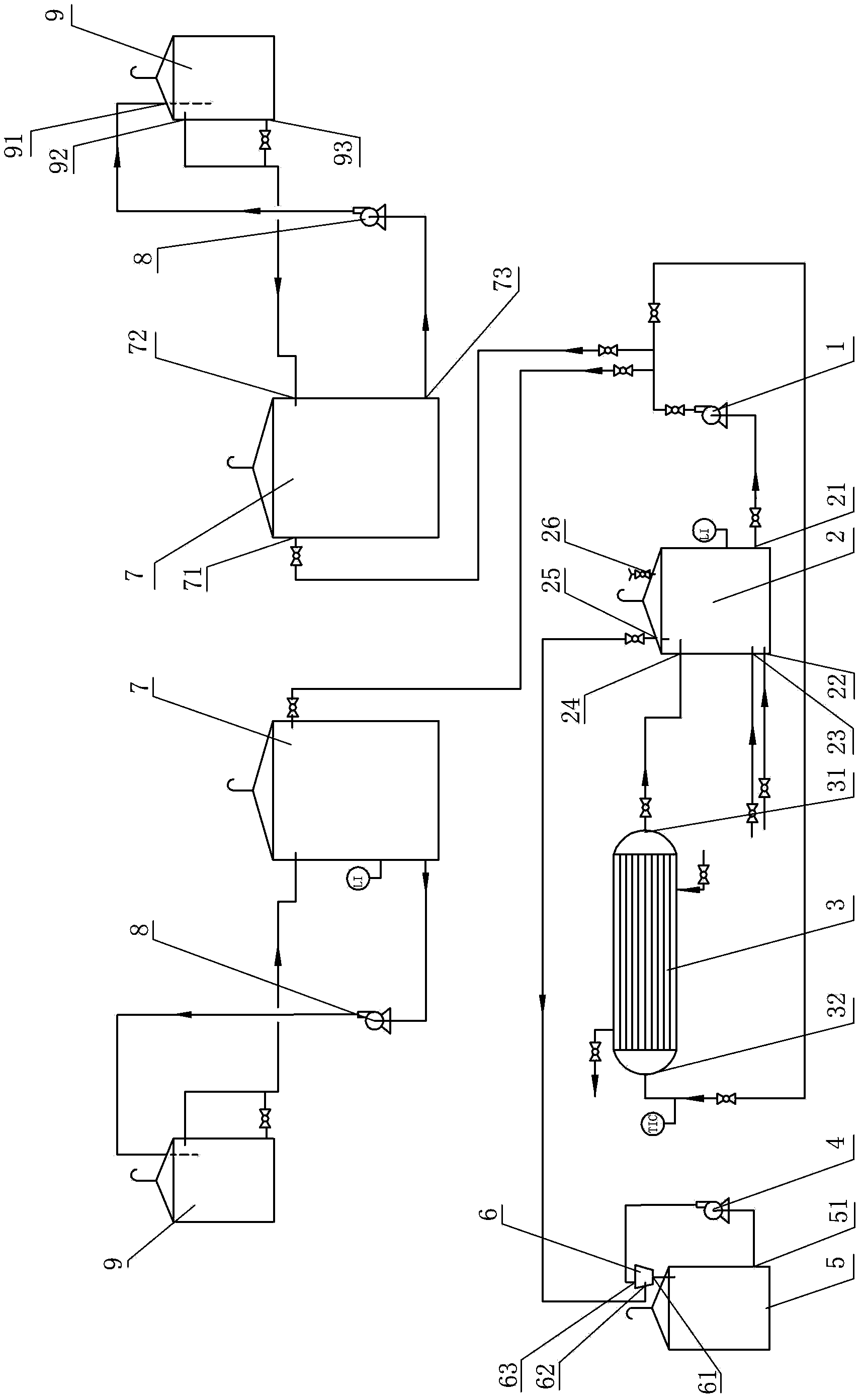

[0021] Embodiment 1: a kind of device of preparation nitric acid aqueous solution, as figure 1 As shown, it includes an acid distribution tank 2, an acid cooler 3, an acid circulation tank 5 and an injector 6. The acid distribution tank is provided with a gas outlet 25, a decolorant feed port 26, a dilute acid feed port 22, and a concentrated acid feed port. Port 23, circulating acid outlet 21 and circulating acid inlet 24, the cooling medium inlet 32 of the acid cooler is connected with the circulating acid outlet of the acid distribution tank through the circulation pump 1, the cooling medium outlet 31 of the acid cooler is connected with the distribution The circulating acid inlet of the acid tank is connected, the gas outlet of the acid distribution tank is connected with the pumped medium inlet 62 of the ejector, the ejector outlet 61 is connected with the acid circulation tank 5, and the acid circulation tank outlet 51 is connected by the pumping negative The pump 4 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com