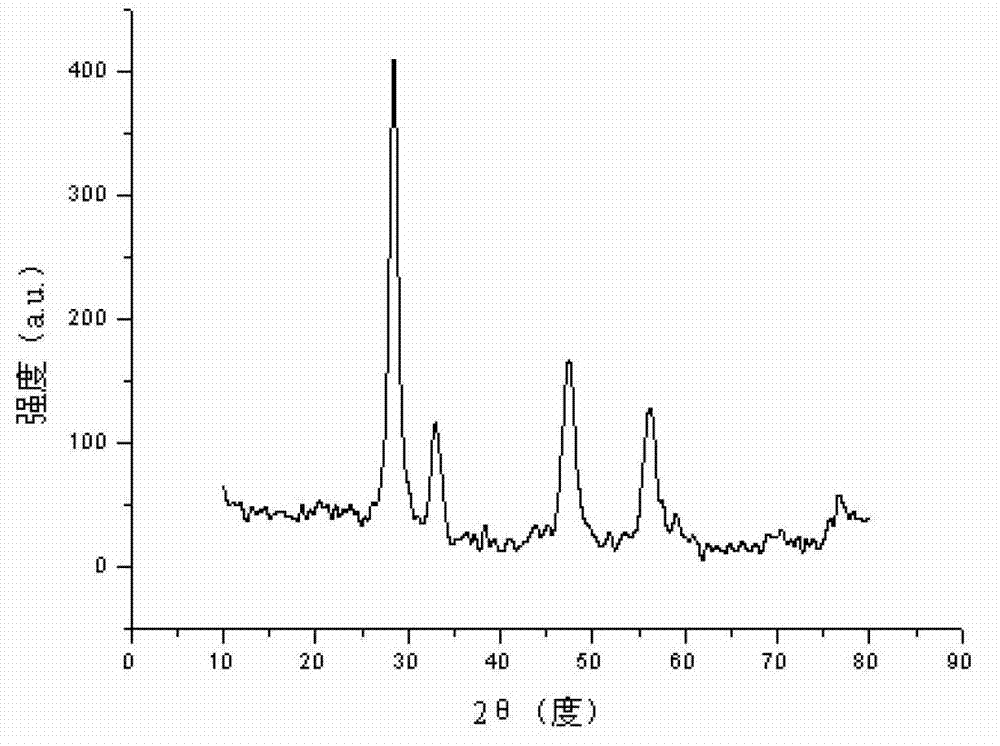

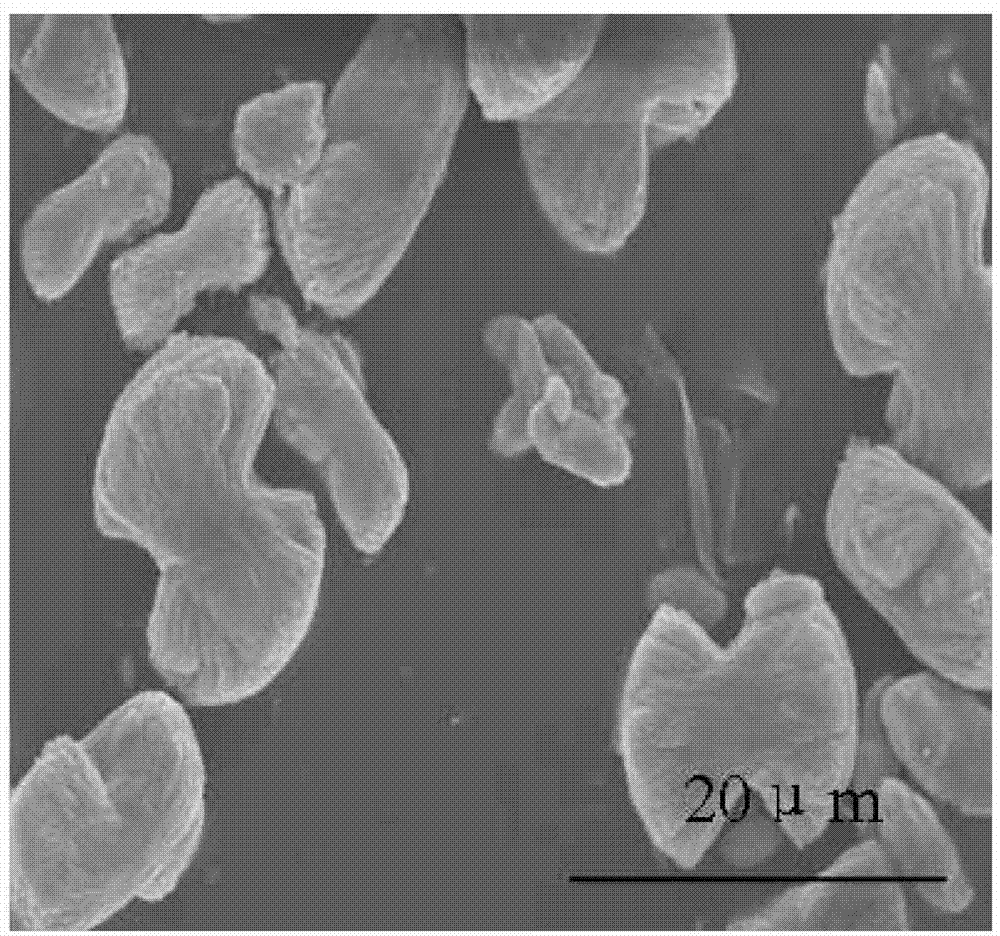

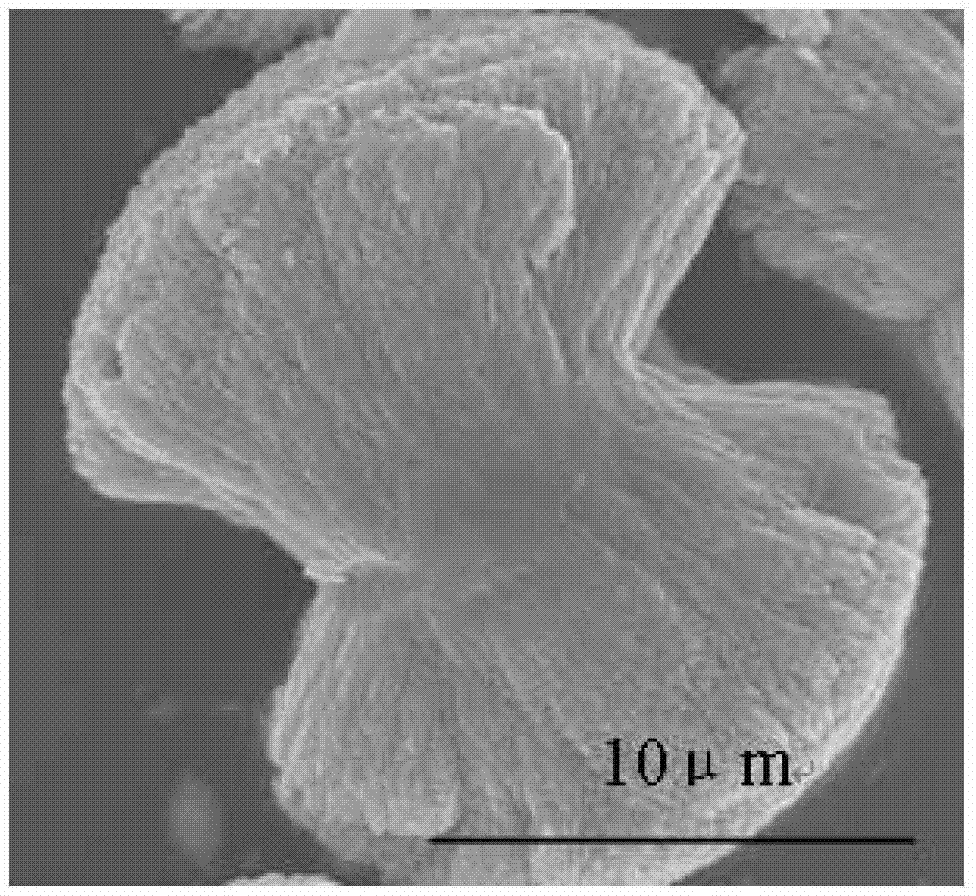

Preparation method of butterfly-tie-shaped cerium dioxide

A technology of cerium dioxide and bow tie, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., to achieve enhanced reaction efficiency, strong oxygen storage and release capabilities, electron transport capabilities, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the preparation method of bowtie-shaped ceria in this embodiment is carried out according to the following steps:

[0018] 1. Add 0.01mol to 0.03mol of Ce(NO 3 ) 3 ·6H 2 O and 0.01mol~0.03mol L-cysteine were mixed and added to 30ml of distilled water and stirred until completely dissolved, then 0.04mol~0.08mol NaOH was added, and the stirring was continued for 30min to obtain a mixed solution;

[0019] 2. Transfer the mixed solution into the reactor and react at 140°C to 180°C for 12h to 36h, take out the reactor and cool it down to room temperature naturally, wash the sample with distilled water until there is no impurity, filter, and store at 80°C to 100°C Dry for 12 hours, and then calcined at 400°C for 1 hour to obtain bowtie-shaped ceria.

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the Ce(NO 3 ) 3 ·6H 2 The molar ratio of O to L-cysteine is 3:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the Ce(NO 3 ) 3 ·6H 2 The molar ratio of O to L-cysteine is 2:1. Others are different from the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com