Formula and manufacturing method of Pleurotus citrinopileatus culture material

A production method and a technology for cultivation materials, which are applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as environmental pollution, and achieve the effects of reducing production costs, rational matching of thickness and size, and beneficial to growth and development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

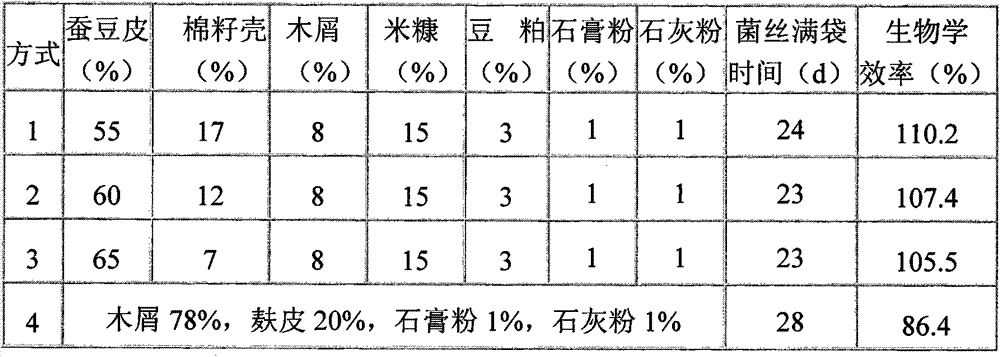

[0024] Method 1: In this example, the cultivation material of P. ulmanii includes the following components and mass ratio: 55% of broad bean hulls, 17% of cottonseed hulls, 8% of sawdust, 15% of rice bran, 3% of soybean meal, 1% of gypsum powder, and lime powder 1%, all for the quality of dry matter, the sum of the proportions is 100%.

[0025] Production Method:

[0026] ① Pre-wetting: Mix broad bean husks, cotton seed hulls, and sawdust dry materials, and pre-wet with 1% lime water (lime powder dissolved in water) for 2 hours to keep the water content of the mixture at 50%-55%;

[0027] ② Mixing material: First mix rice bran, soybean meal and gypsum powder dry material, then add it to the pre-wet mixed material, then slowly add water, mix while adding, fully stir evenly, so that the water content of the cultivation material can be kept at 63%-65%;

[0028] ③ Bagging: Use polypropylene plastic bags with specifications of 17cm×35cm×0.005cm, each bag contains 1100g-1200g of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com