Cheese dyeing method for aramid yarns or aramid sewing threads

A technology for dyeing aramid yarn and bobbins, which is applied in the fields of dyeing, textiles and papermaking, fiber treatment, etc. It can solve the problems of inability to produce fluorescent colored fibers, limited application space of aramid fibers, and poor dyeing fastness, and achieve Effects of improving color fastness, solving limitations, and reducing dyeing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Fluorescent yellow dyeing of aramid yarn

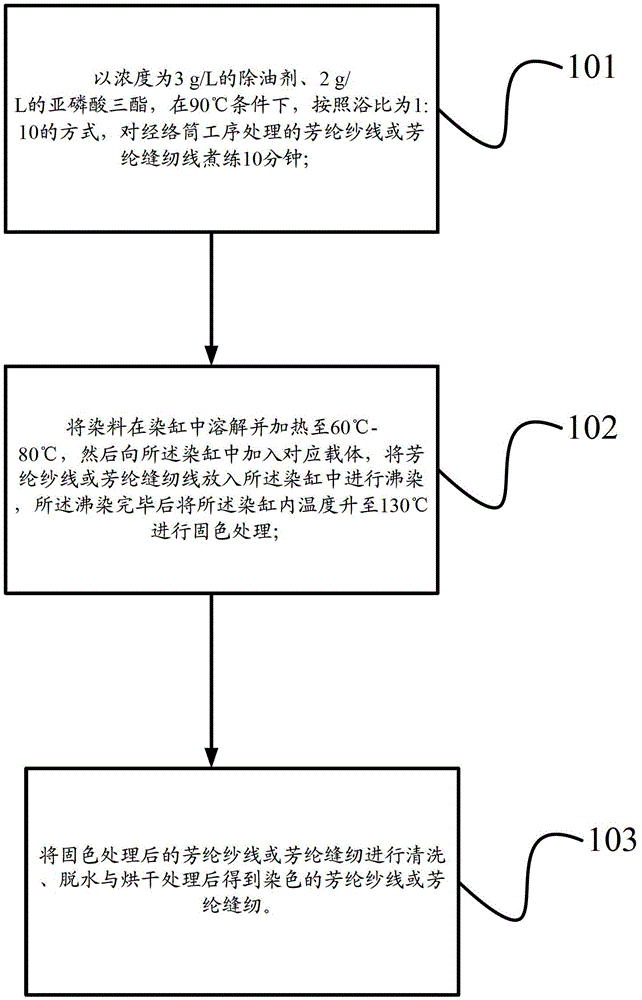

[0043]Smelt the bobbins first: use a degreasing agent with a concentration of 3g / L and a phosphite triester with a concentration of 2g / L at a temperature of 90°C with a liquor ratio of 1:10 to process the yarn in the meridian winding process. Aramid yarn or aramid sewing thread boil for 10 minutes.

[0044] Dissolve the fluorescent yellow dye in the dyeing vat, and ensure that the concentration of the dye in the dyeing vat is: cationic Y10GFF0.42-0.48g / L, acetic acid 3-3.5g / L and sodium chloride 20g / L, then heat the dye to 70°C, then add carrier HPS505 into the dye vat, the concentration of HPS505 is 40g / L, run for 5-10 minutes, heat the mixture in the dye vat to boiling within 60 minutes for boiling dyeing.

[0045] After the boiling dyeing is completed, the pH value of the mixture in the dyeing vat is adjusted to 9, the dyeing is incubated at 130°C for 30 minutes, and then the color is fixed for 30 minutes. After the color ...

Embodiment 2

[0053] Fluorescent yellow dyeing of aramid sewing thread

[0054] Smelt the bobbins first: use a degreasing agent with a concentration of 3g / L and a phosphite triester with a concentration of 2g / L at a temperature of 90°C with a liquor ratio of 1:10 to process the yarn in the meridian winding process. Aramid yarn or aramid sewing thread boil for 10 minutes.

[0055] Dissolve the fluorescent yellow dye in the dyeing vat, and ensure that the concentration of the dye in the dyeing vat is: cationic Y10GFF0.42-0.48g / L, acetic acid 3-3.5g / L and sodium chloride 20g / L, then heat the dye to 70°C, then add the carrier HPS505 into the dyeing vat, the concentration of HPS505 is 40g / L, run for 5-10 minutes, heat the mixture in the dyeing vat to boiling within 60 minutes and carry out boiling dyeing for 60 minutes.

[0056] After the boiling dyeing is completed, the pH value of the mixture in the dyeing vat is adjusted to 9, the dyeing is incubated at 130°C for 30 minutes, and then the col...

Embodiment 3

[0063] Dyeing navy blue A color on aramid yarn

[0064] Smelt the bobbins first: use a degreasing agent with a concentration of 3g / L and a phosphite triester with a concentration of 2g / L at a temperature of 90°C with a liquor ratio of 1:10 to process the yarn in the meridian winding process. Aramid yarn or aramid sewing thread boil for 10 minutes.

[0065] Dissolve the dye for dyeing navy blue A color in the dyeing vat, and ensure that the concentration of the dye in the dyeing vat is: Y X-GL1.8g / L, R X-GRL0.78g / L, B X-BL2.1g / L, acetic acid 3 -3.5g / L and sodium chloride 20g / L, then heat the dye to 60°C, then add the carrier HPS303 into the dye vat, the concentration of HPS303 is 40g / L, run for 5-10 minutes, put the mixture in the dye vat Heat up to boiling within 60 minutes and carry out boiling dyeing for 60 minutes.

[0066] After the boiling dyeing is completed, the pH value of the mixture in the dyeing vat is adjusted to 9, the dyeing is incubated at 130°C for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com