Connection structure of building composite floor slab and steel bar truss shear wall

A technology of superimposed floor slabs and steel trusses, which is applied to building structures and buildings, can solve problems such as unreasonable overall assembly and connection structures, inconvenient operation of components, and impact on prefabricated buildings, so as to shorten the construction period and improve building quality. , Good effect of on-site assembly and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and specific embodiments to help understand the content of the present invention.

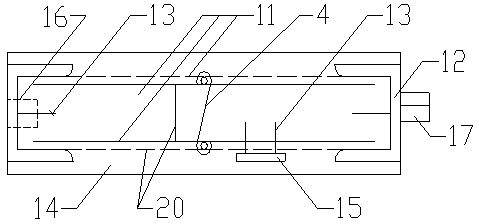

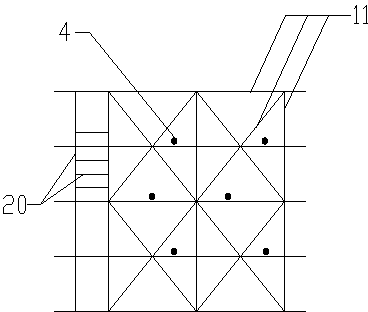

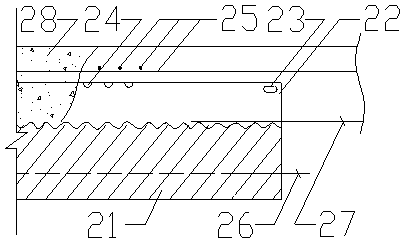

[0016] Such as figure 1 , 2 As shown, the prefabricated shear wall is equipped with a steel truss 11, the wall of the shear wall also has embedded steel plates 15 for connecting with other components, a peripheral steel frame 12, and an anchor 13 The steel frame 12, the embedded steel plate 15 and the precast concrete 14 are connected by small steel, steel plate strips, anchor bars and studs. The connection of the steel frame 12, the embedded steel plate 15 and the precast concrete 14 is also realized by the anchor rod 13 welded with the steel frame 12 and the embedded steel plate 15. The frame 12 is welded, the shear wall has an edge-constrained reinforcing steel frame 20, a pit 16 is left at the end of the shear wall, and the lower end is welded with a short steel connector 17; specific manufacturing imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com