Portable cement paste injection pressure gun

A cement slurry and pressure gun technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of affecting the quality of grouting, the space is small, and it is not suitable for large-scale pressure grouting machine. Guaranteed construction quality, easy to move and carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

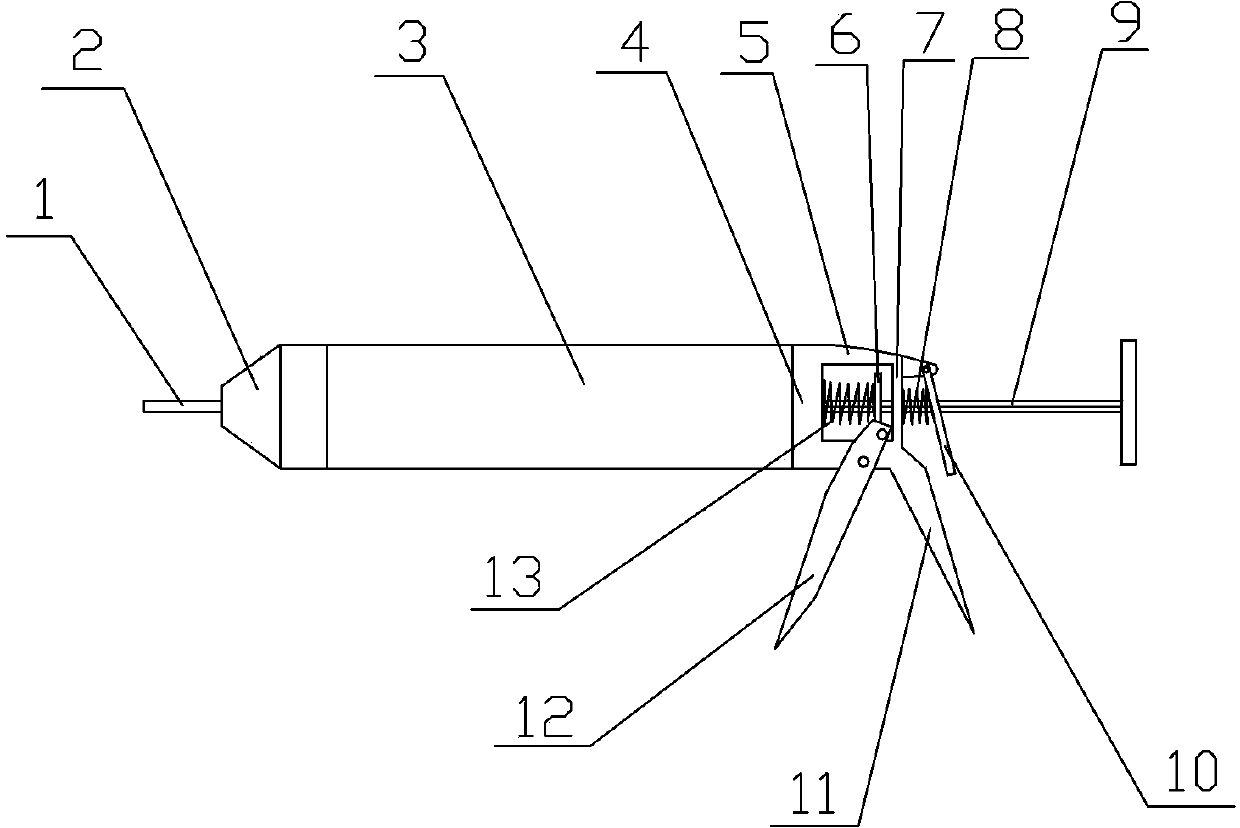

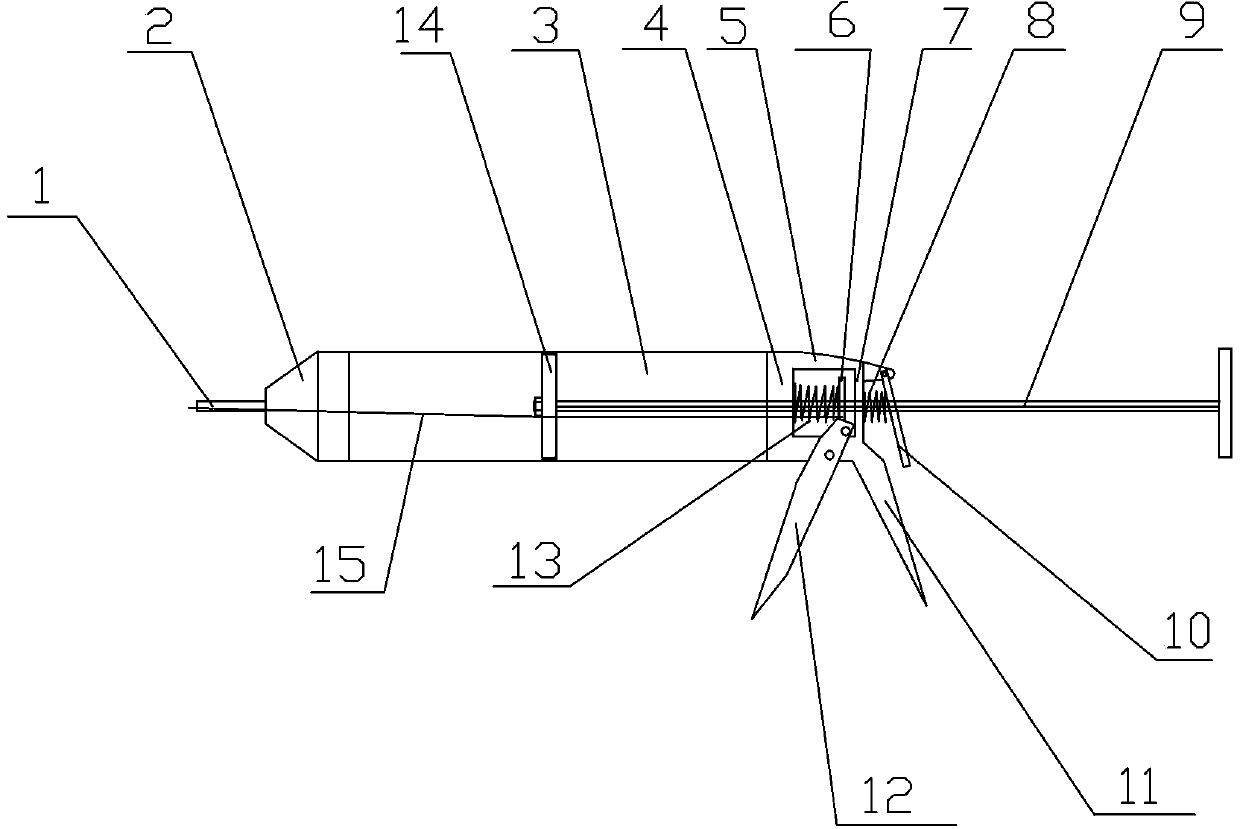

[0023] Such as Figure 1 to Figure 6 As shown, the portable cement slurry filling pressure gun of the present invention includes a gun cap 2, a slurry storage cylinder 3, a piston 14, a push rod 9, a dredging needle 15, a gun handle 11, a trigger 12, a push plate 6, a fixed plate 10, and a spring I 13 , Spring II 8.

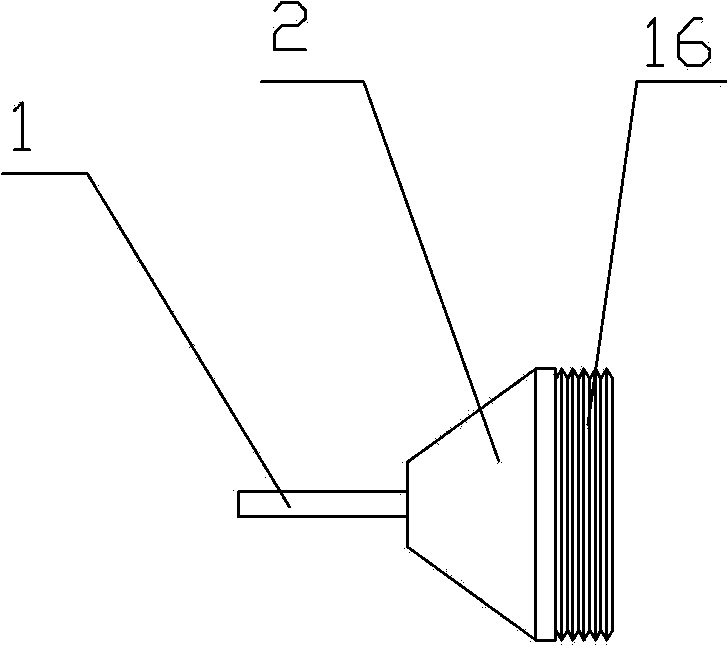

[0024] The front end of the gun cap 2 is provided with a slurry nozzle 1 communicating with the inner side of the gun cap 2, and the rear end of the gun cap 2 is connected to the front end of the slurry storage tube 3. In this embodiment, the gun cap 2 is made of stainless steel, and the slurry storage tube 3 is made of stainless steel. The hollow cylinder is made, the outer wall of the rear end of the gun cap 2 is provided with an external thread 16, and the inner side wall of the front end of the slurry storage tube 3 is provided with an internal thread (not shown in the figure), and the gun cap 2 and the slurry storage tube 3 are connected by threads. Of cour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com