Combustion system of boiler and combustion method implemented by aid of system

A boiler combustion and flue gas technology, which is applied in the combustion method, control combustion, lighting and heating equipment, etc., can solve the problems of large amount of flue gas recirculation, damage to the furnace body, and high cost of oxygen station construction, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

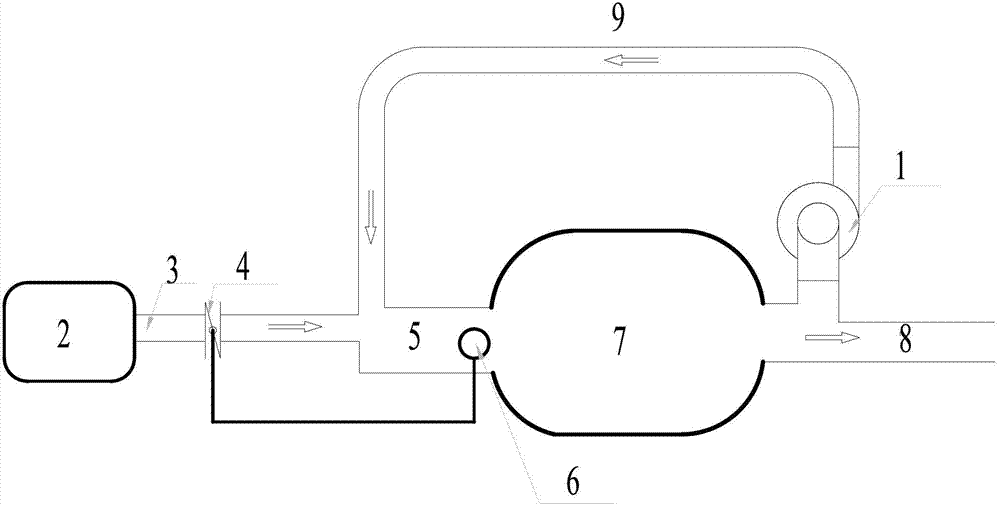

[0031] Boiler combustion system:

[0032]The gas separator 2, the inlet main flue 5, the boiler 7, and the flue gas outlet 8 are connected in sequence; the N separated by the gas separator 2 2 discharge, O 2 Enter the inlet main flue 5; an oxygen delivery baffle door 4 is set between the gas separator 2 and the inlet main flue 5, and the gas composition online monitoring device 6 is arranged in the inlet main flue 5, and is connected with the oxygen delivery baffle door 4-phase connection; the flue gas from the flue gas outlet 8 enters the circulating flue 9 through the induced draft fan 1 and the O separated by the gas separator 2 2 Recombine into auxiliary gas and inject into main flue 5 at the entrance to participate in combustion.

[0033] The fuel combustion method of the present invention utilizes the above-mentioned boiler combustion system, and the gas separator is used to separate air to obtain O 2 , the oxidant during combustion is O obtained by gas separation 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com