Preparation of single or small tube bundle size single-walled carbon nanotube transparent conductive film

A single-walled carbon nanotube, transparent conductive film technology, applied in the direction of carbon nanotubes, nanocarbon, nanotechnology, etc., can solve the problems of unstable chemical doping, the attenuation of the transparent conductive performance of the film over time, and achieve a simple process. , The effect of reducing the probability of collision and reducing the contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

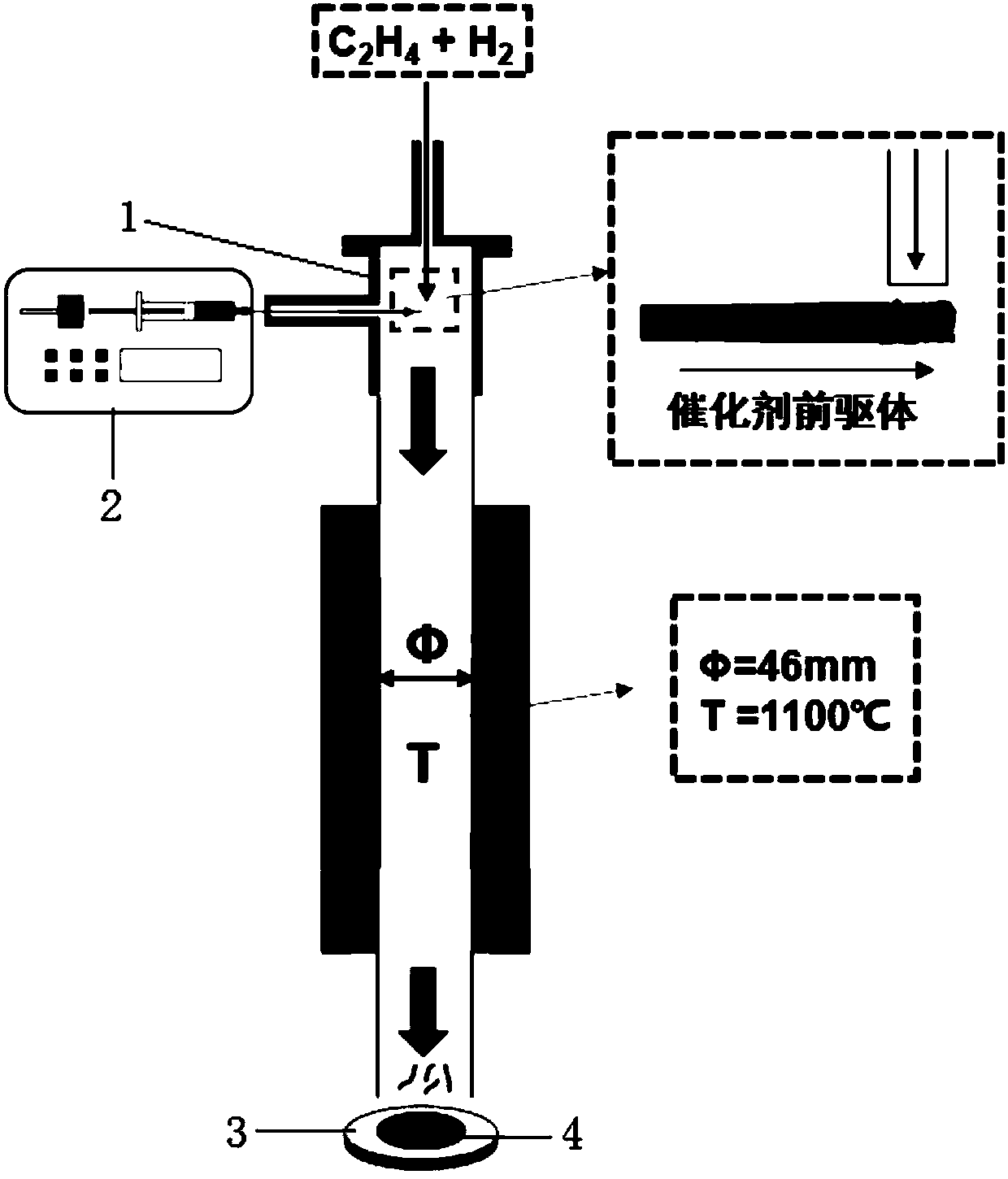

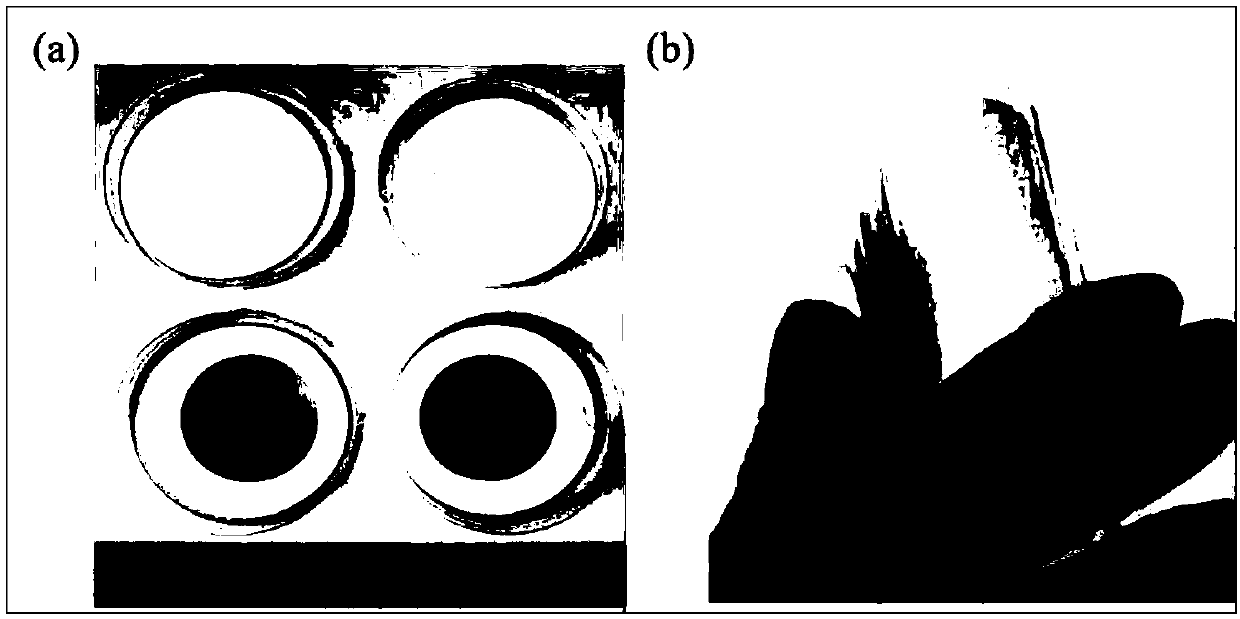

[0039] In this embodiment, under the protection of 1000 sccm of argon, the temperature of the reaction furnace is first raised to 1100 ° C, and then 6500 sccm of carrier gas hydrogen and 11 sccm of gas-phase carbon source ethylene are introduced, and the liquid-phase carbon source toluene, catalyst front The mixed solution (mass ratio of 10:0.3:0.045) of body ferrocene and growth promoter thiophene is injected into the reaction furnace at a speed of 0.1 ml / hour, see figure 1 . The single-wall carbon nanotube film grown in the reaction furnace forms a single-wall carbon nanotube film on the porous filter membrane at the lower end of the reactor. Films of varying thickness (light transmittance) are obtained by controlling the collection time and can be dry-transferred onto flexible substrates polyethylene terephthalate (PET), see figure 2 .

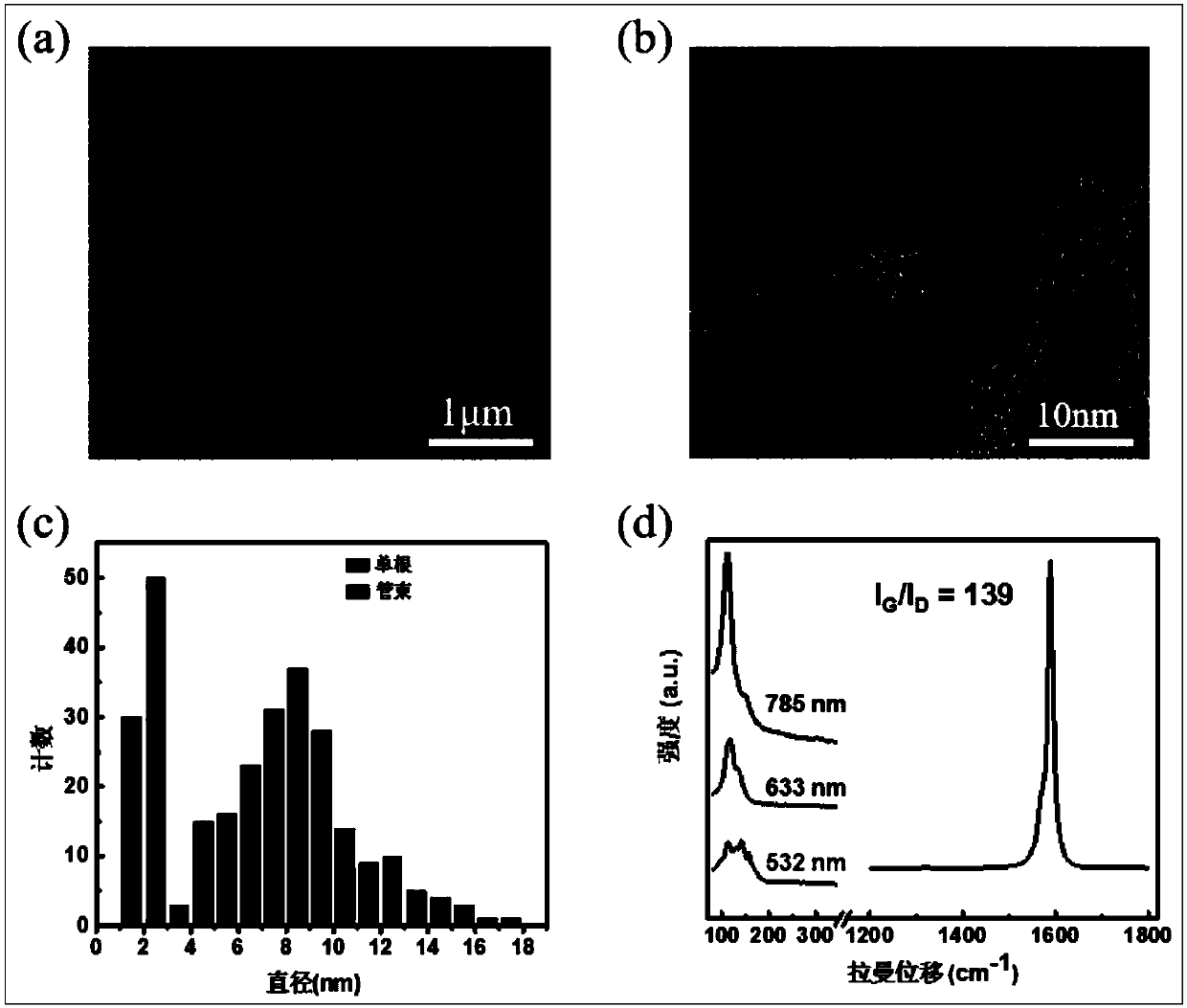

[0040] Such as image 3 As shown in (a), scanning electron microscope characterization found that the carbon nanotube film was uniform...

Embodiment 2

[0043] In this embodiment, under the protection of 800 sccm of argon, the temperature of the reaction furnace is raised to 1050° C., and then 7000 sccm of carrier gas hydrogen and 11 sccm of gas-phase carbon source acetylene are introduced, and the liquid-phase carbon source benzyl alcohol, catalyst The mixture of precursor ferrocene and growth promoter sulfur powder (mass ratio 9:0.4:0.05) was injected into the reaction furnace at a rate of 0.2 ml / hour. The single-wall carbon nanotube film grown in the reaction furnace forms a single-wall carbon nanotube film on the porous filter membrane at the lower end of the reactor. Films of different thicknesses (light transmittance) were obtained by controlling the collection time, and could be transferred to the flexible substrate PET by dry method.

[0044] Scanning electron microscope characterization found that the carbon nanotube film was uniform and pure, and transmission electron microscope observation further verified the high ...

Embodiment 3

[0047] In this embodiment, under the protection of 1200 sccm of argon, the temperature of the reaction furnace is first raised to 1150 ° C, and then 7000 sccm of carrier gas hydrogen and 11 sccm of gas-phase carbon source methane are introduced, and the liquid-phase carbon source benzene, catalyst front The mixed solution of body ferrocene and growth promoter thiophene (mass ratio 10:0.35:0.045) was injected into the reaction furnace at a rate of 0.2 ml / hour. The single-wall carbon nanotube film grown in the reaction furnace forms a single-wall carbon nanotube film on the porous filter membrane at the lower end of the reactor. Films of different thicknesses (light transmittance) were obtained by controlling the collection time, and could be transferred to the flexible substrate PET by dry method.

[0048] Scanning electron microscopy showed that the carbon nanotube film was uniform and pure. The transmission electron microscope observation further verified the high purity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| anti-oxidation temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com