Hot embedding method for gold-phase sample preparation of thin steel wires

A technology of metallographic sample preparation and thermal mounting, which is applied in the field of thermal mounting, can solve the problems of long sample mounting period, high cost, damage to roundness and flatness of steel wire cross section, etc., and achieve good detection effect, fast detection effect, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

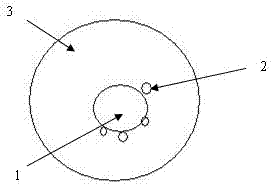

[0022] see figure 1 , figure 1 It is a schematic diagram of the operation of the hot mounting method for fine-gauge steel wire metallographic sample preparation of the present invention. Depend on figure 1 It can be seen that the thermal embedding method of fine-gauge steel wire metallographic sample preparation of the present invention, said method comprises the following process steps:

[0023] Step 1. Making fine-gauge steel wire samples

[0024] Cut the fine-gauge steel wire to be tested, grind the end face (cross section) of the cut-off fine-gauge steel wire into a plane with a grinding wheel or sandpaper, remove the burr, and make a fine-gauge steel wire sample, the diameter of which is less than 1.0mm, and the length is 5mm. ~10mm;

[0025] Step 2. Making coarse-gauge steel wire samples

[0026] Select a thick-gauge steel wire with the same or similar material as the fine-gauge steel wire to be tested. The cross-section can be circular or rectangular. Grind one end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com