Fabric water-permeability resistance hydrostatic pressure tester as well as control system and testing method thereof

A testing method and testing machine technology, applied in the direction of electrical program control, program control in sequence/logic controller, measuring device, etc., can solve problems such as inability to adjust hydrostatic pressure, small detection range, and difficult sealing structure, etc., to achieve Improve the efficiency of hydrostatic pressure testing, adjust water flow sensitively, and facilitate processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

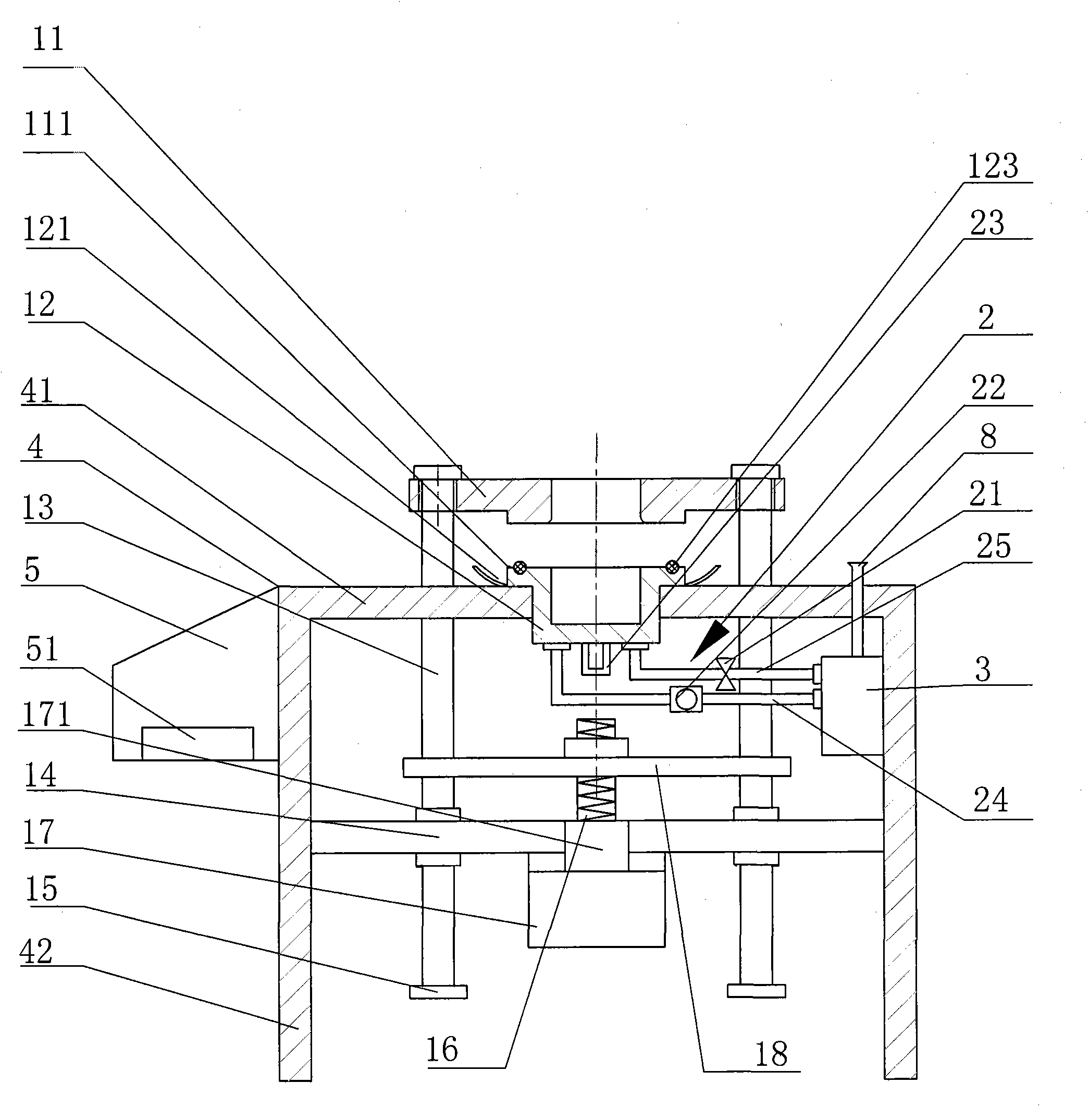

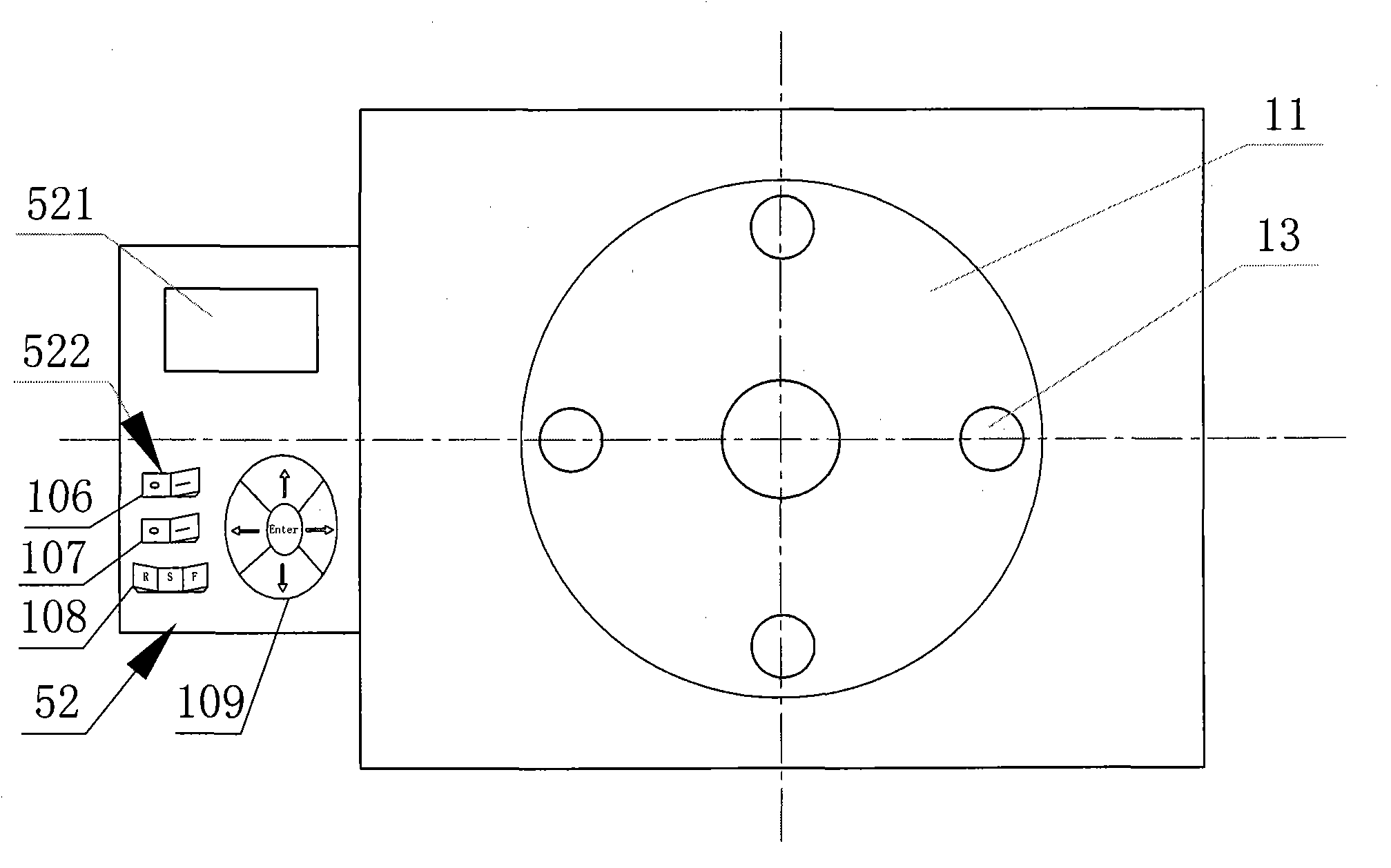

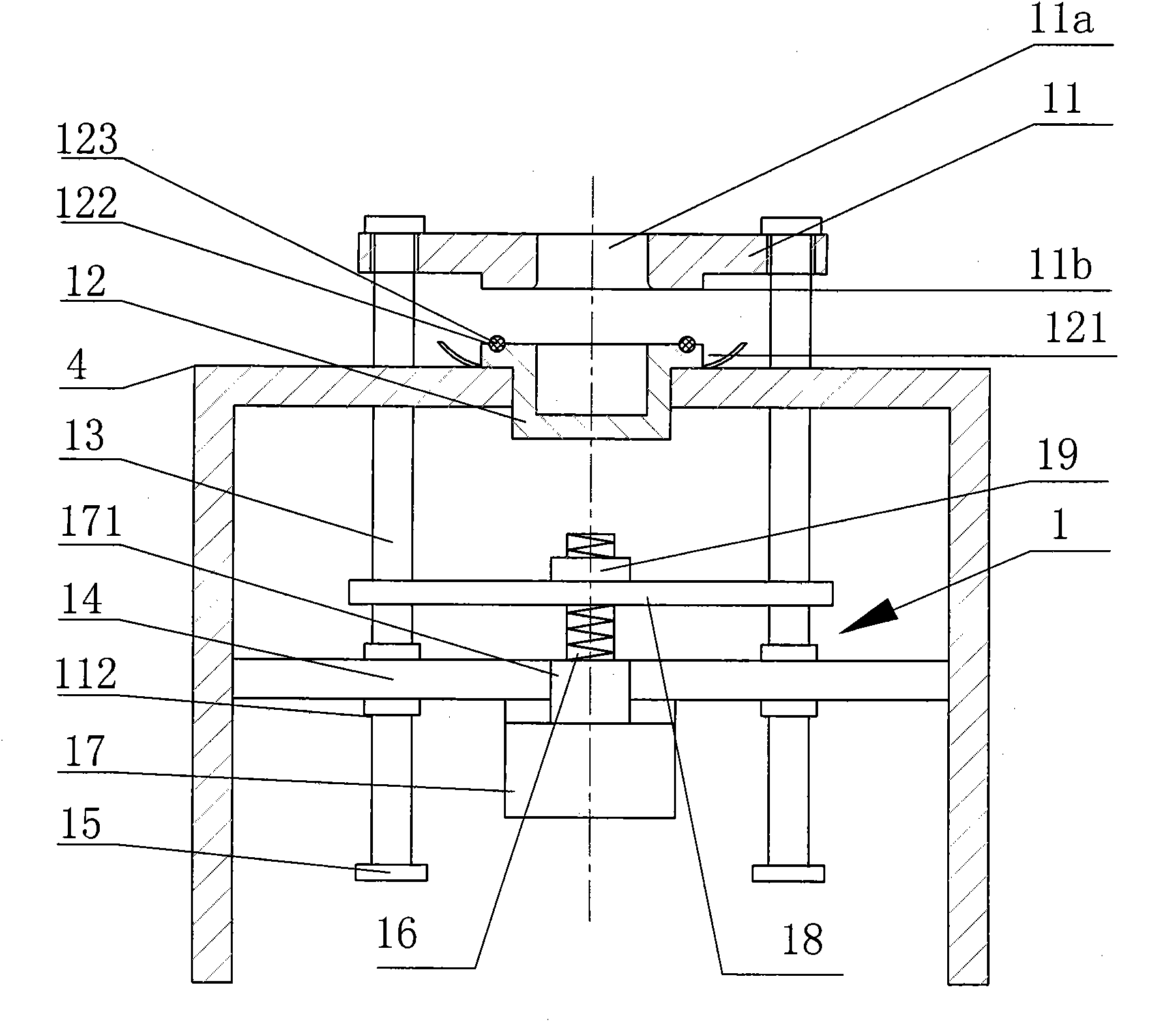

[0054] refer to figure 1 , figure 2 and image 3 Shown, a kind of fabric impermeability hydrostatic pressure testing machine of the present invention comprises frame 4, pressurization tank 12, clamping mechanism 1, pressurization / pressure relief mechanism 2 and water storage tank 3.

[0055] The frame 4 includes a support plate 41 and a support foot 42 , the support plate 41 is located at the top of the support foot 42 , and the guide seat 14 is fixed in the middle of the support foot 42 . A through hole is opened on the support plate 41, and the cylindrical pressurized water tank 12 is arranged in the through hole and fixed on the support plate 41. The bottom surface of the pressurized water tank 12 is arranged below the support plate 41, but is located Above; the top surface of the pressurized water tank 12 is provided with an arc-shaped groove 122, and the arc-shaped groove 122 is provided with a sealing ring 123, and the sealing ring 123 is an O-shaped sealing ring, and...

Embodiment 2

[0064] The driving part in the present embodiment comprises the screw mandrel 16 that is rotatably connected on the guide seat 14 and the nut 19 that is fixed on the connecting plate 18, and the upper end of the screw mandrel 16 cooperates with the nut 19, and the lower end of the screw mandrel 16 is provided with a rotating handle . The circumferential rotation of the screw rod 16 makes the nut 19 move up and down along the screw rod 16, that is, the connecting plate 18 moves up and down, thereby driving the four guide rods 13 to drive the pressing plate 11 to move up and down, so as to realize the clamping and loosening of the fabric. open. Other structures in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0066] The driver in the present embodiment includes a motor 17 fixed on the guide seat 14, a gear connected to the output shaft of the motor 17 and a rack vertically fixed on the connecting plate 18, the gear and the rack cooperate, and the motor 17 The circumferential rotation of the output shaft is converted into the up and down movement of the rack through the cooperation of the gear and the rack, that is, the connecting plate 18 moves up and down, thereby driving the four guide rods 13 to drive the pressing plate 11 to move up and down, realizing the fabric Clamp and loosen. Other structures in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com