Adjustable Laser Gas Telemeter and Its Focal Plane Adjustment Method

A laser gas, adjustable technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problem of being unable to meet the high-sensitivity measurement of long-distance and short-distance at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

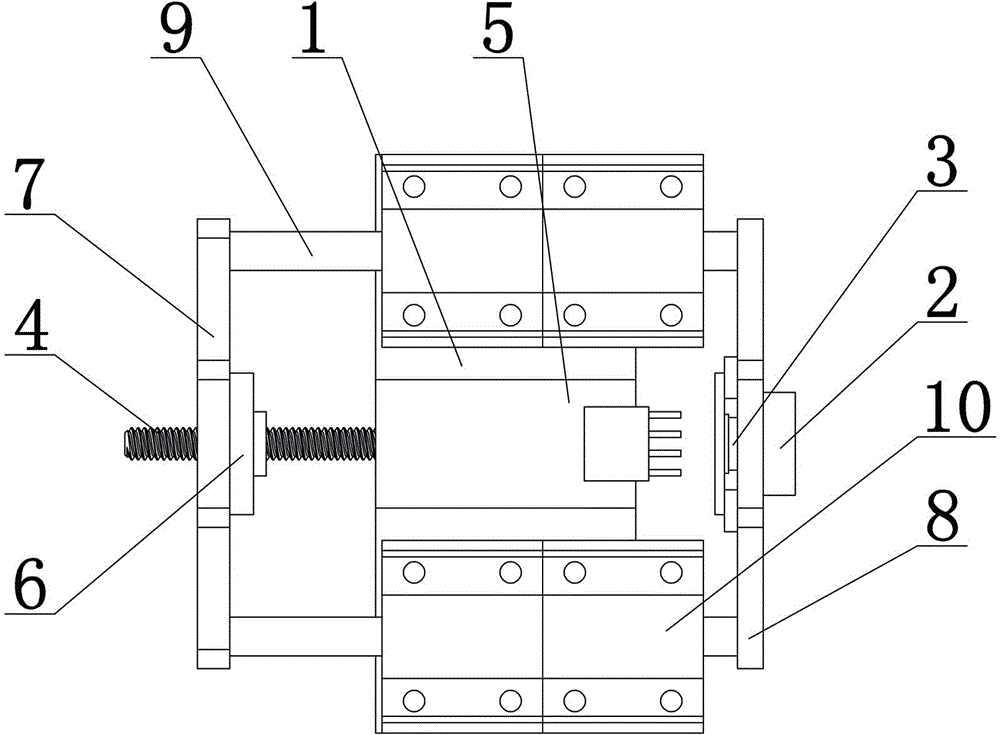

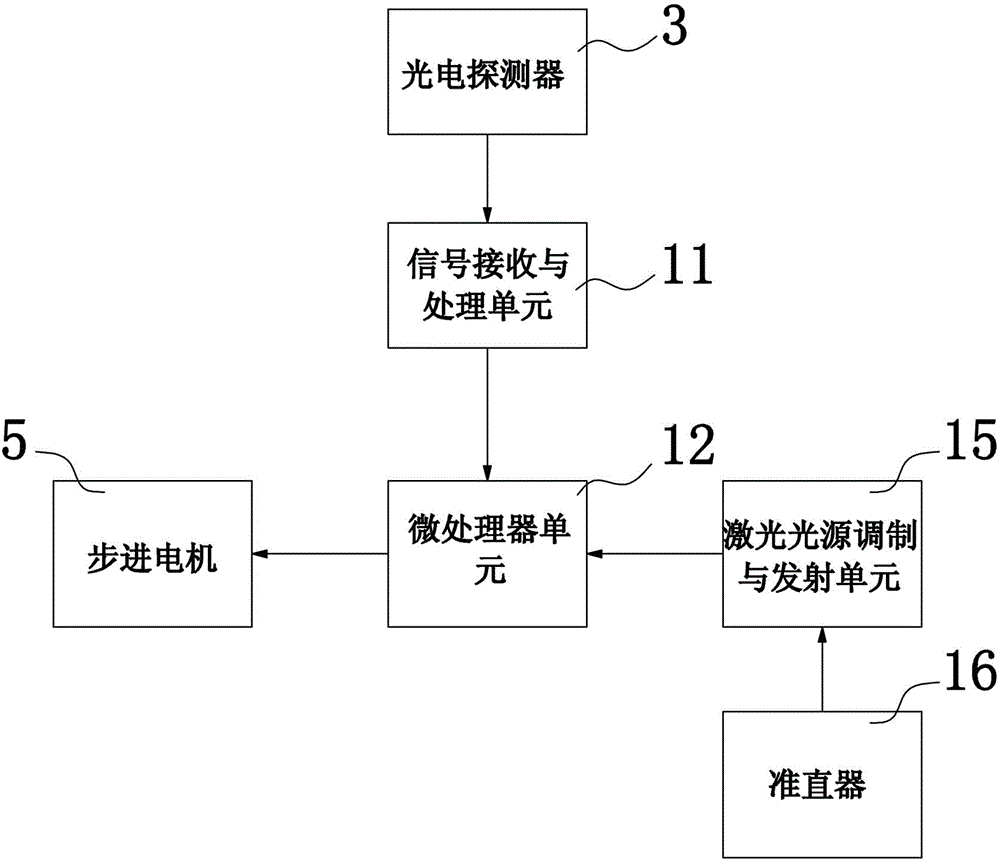

[0026] Such as figure 1 and figure 2 As shown, an adjustable laser gas telemetry instrument includes a microprocessor unit 12, a signal receiving and processing unit 11 electrically connected to the microprocessor unit 12, and a photodetector electrically connected to the signal receiving and processing unit 11 3. The optical filter 2 used in conjunction with the photodetector 3, the laser light source modulation and emission unit 15 electrically connected to the microprocessor unit 12, the collimator electrically connected to the laser light source modulation and emission unit 15 16. Condenser and focal plane adjustment mechanism. The condenser lens is generally a Fresnel lens, a concave mirror or a convex lens. The focal plane adjustment mechanism includes a base 1, a stepping motor 5 installed on the base 1, and a The leading screw 4 and the mounting frame on the output shaft of the stepping motor 5, the mounting frame is provided with a leading screw hole, the leading sc...

Embodiment 2

[0028]The difference between this embodiment and Embodiment 1 is that the mounting frame includes a guide rail, an adjustment plate arranged at one end of the guide rail, and a fixing plate arranged at the other end of the guide rail, and the screw hole is arranged on the adjustment plate. On the plate, the photodetector and the filter are installed on the fixed plate, and the base is provided with a guide rail guide hole, the guide rail is set in the guide rail guide hole, and the guide rail guide hole is arranged on the base On the other hand, it can also ensure the stable running of the fixed plate and the adjusting plate, saving the design of the slider.

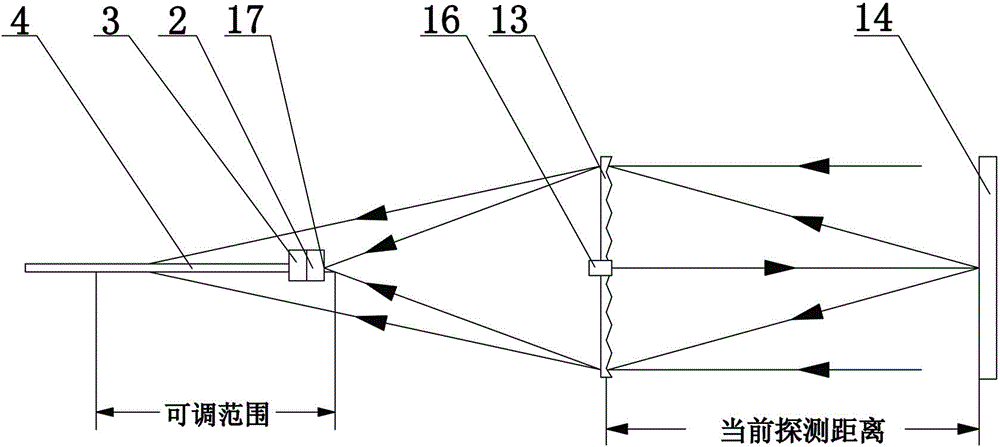

[0029] Such as image 3 As shown, a focal plane adjustment method of an adjustable laser gas telemeter, the focal plane adjustment method includes the following steps:

[0030] Step 1. Determine the calibration point at the current detection distance: start the adjustable laser gas telemeter, and the microprocessor unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com