Microlens, microlens array structure and manufacturing process thereof

An array structure and microlens technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of low resolution, crosstalk, incomplete image distinction, etc., to improve resolution, reduce crosstalk, Distinguish obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

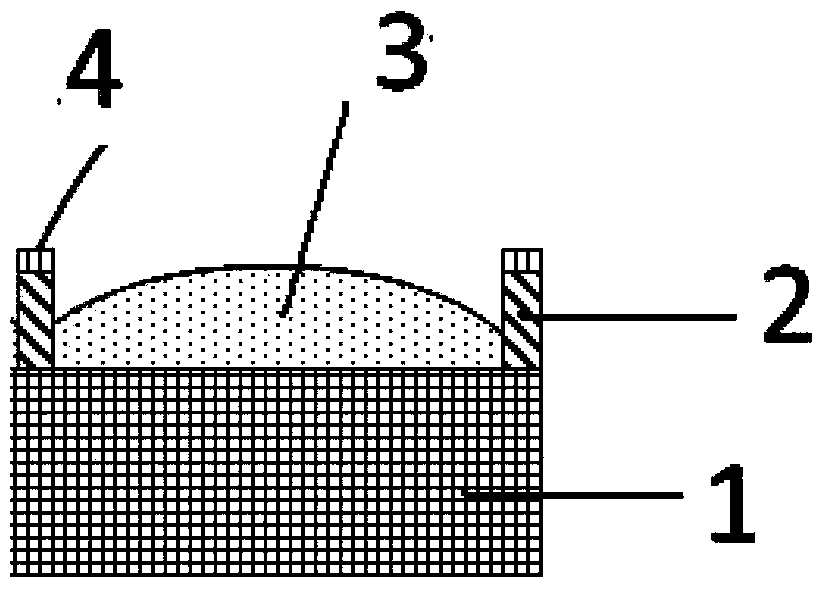

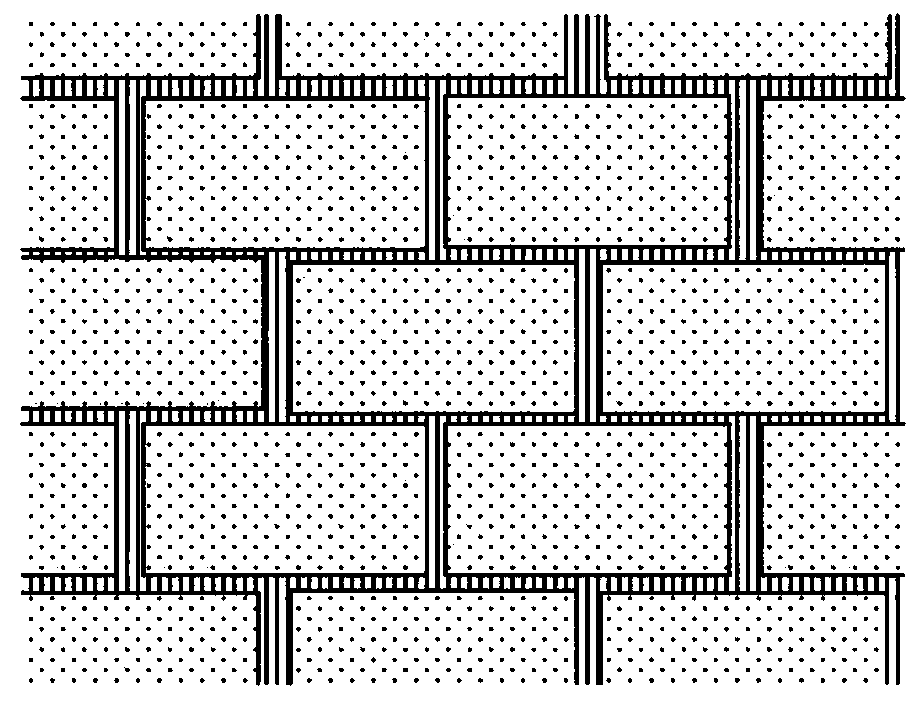

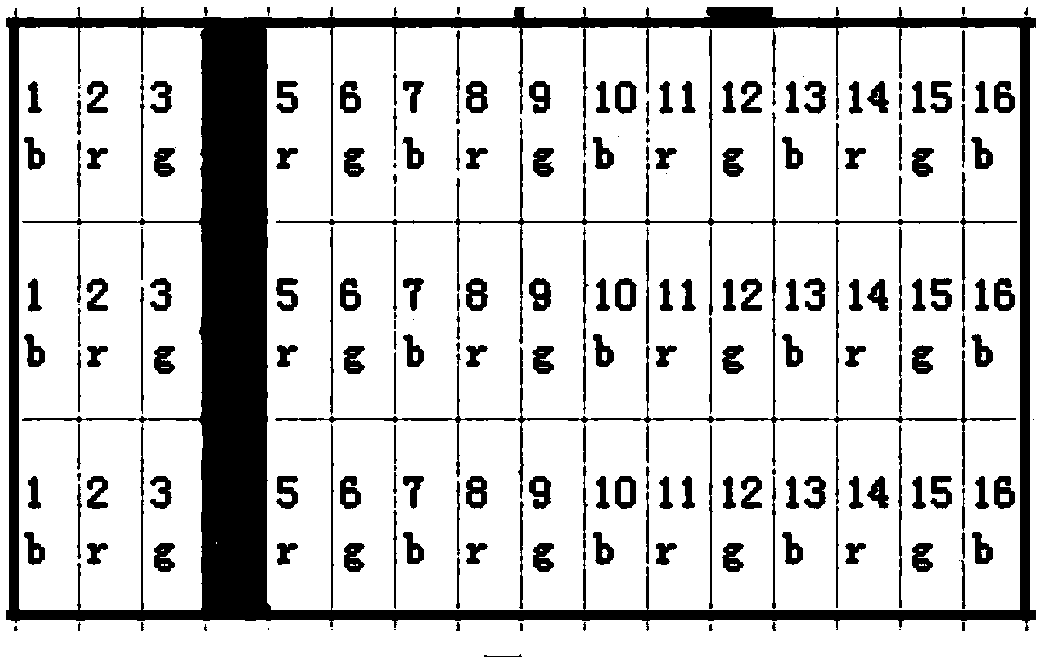

[0039] Microlens array is an optical device widely used in three-dimensional stereoscopic display. The microlens array is used in the acquisition stage and reproduction stage of integrated imaging, and its size, shape, focal length and other parameters have an important impact on the image display quality. Therefore, the preparation of a microlens array that meets the requirements is very critical for the research of integrated imaging. The manufacturing process of the present invention mainly has five steps. In the manufacturing process, each step requires high precision, so that the manufactured microlens array can have good uniformity and consistent optical characteristics. The method of implementation is as follows:

[0040] (1) Lamination

[0041] Microlens arrays are generally fabricated on glass substrates, first by cleaning the glass substrates and cutting them into required dimensions. Then, the photoresist is pressed on the glass substrate with a lamination machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com