Permanent magnet synchronous motor temperature rise heat dissipation analysis method based on multi-field coupling technology

A permanent magnet synchronous motor and analysis method technology, applied in the field of simulation, can solve problems that affect the accuracy of temperature rise and heat dissipation analysis, affect the reliability of motor design, and cannot guarantee the temperature continuity and energy conservation of the coupling interface, so as to improve the calculation accuracy and Calculation efficiency, effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the present invention is further described below in conjunction with accompanying drawing and specific embodiment:

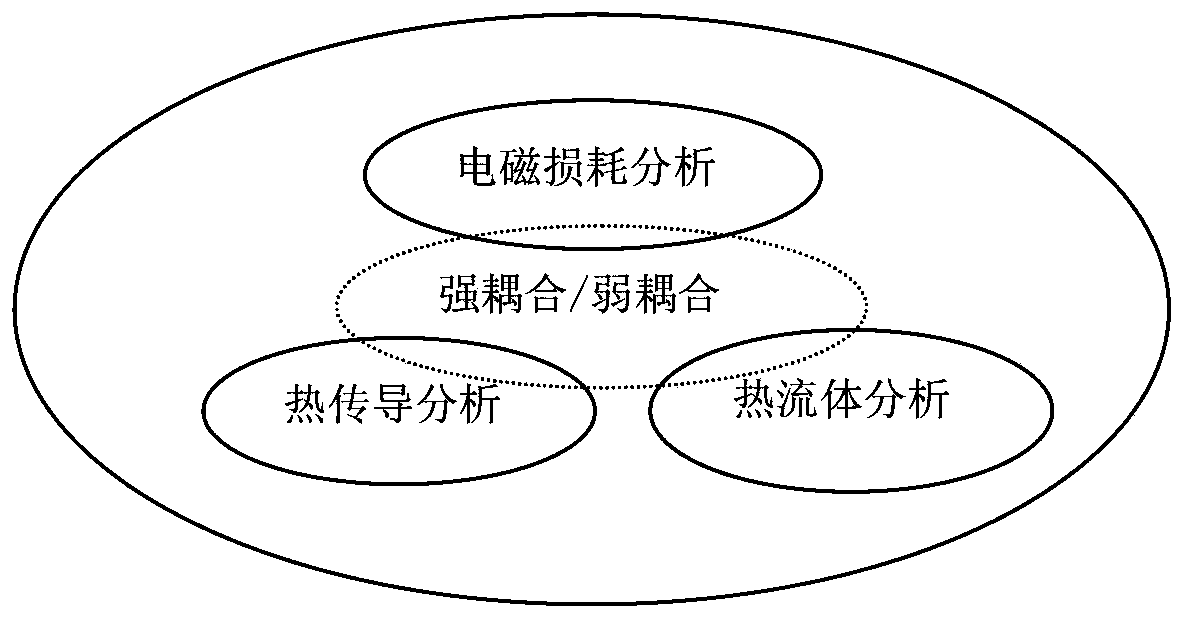

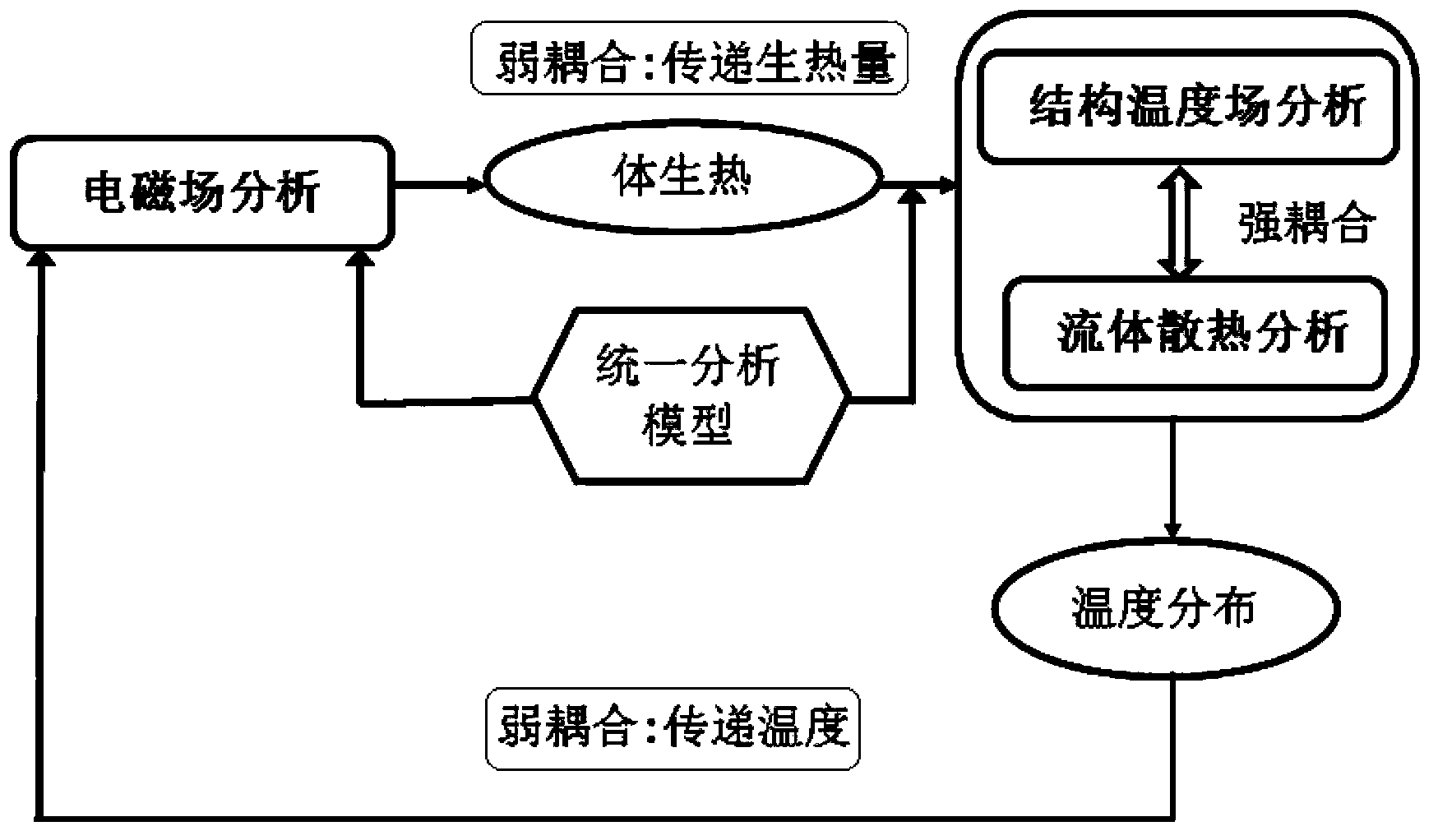

[0021] like figure 2 As shown, the present invention integrates the analysis functions of electromagnetic-temperature-fluid field, and realizes the integration of electromagnetic loss analysis function, structural heat conduction analysis function and fluid heat dissipation analysis function under a unified software platform. Specifically, such as image 3 As shown, the strong coupling of structural temperature field analysis and non-matching mesh of fluid heat dissipation analysis is realized by the multi-point constraint method; the electromagnetic loss analysis and fluid-solid conjugate heat conduction analysis are realized by the load transfer coupling technology of the inter-solution coupling interface. Two-way weak coupling.

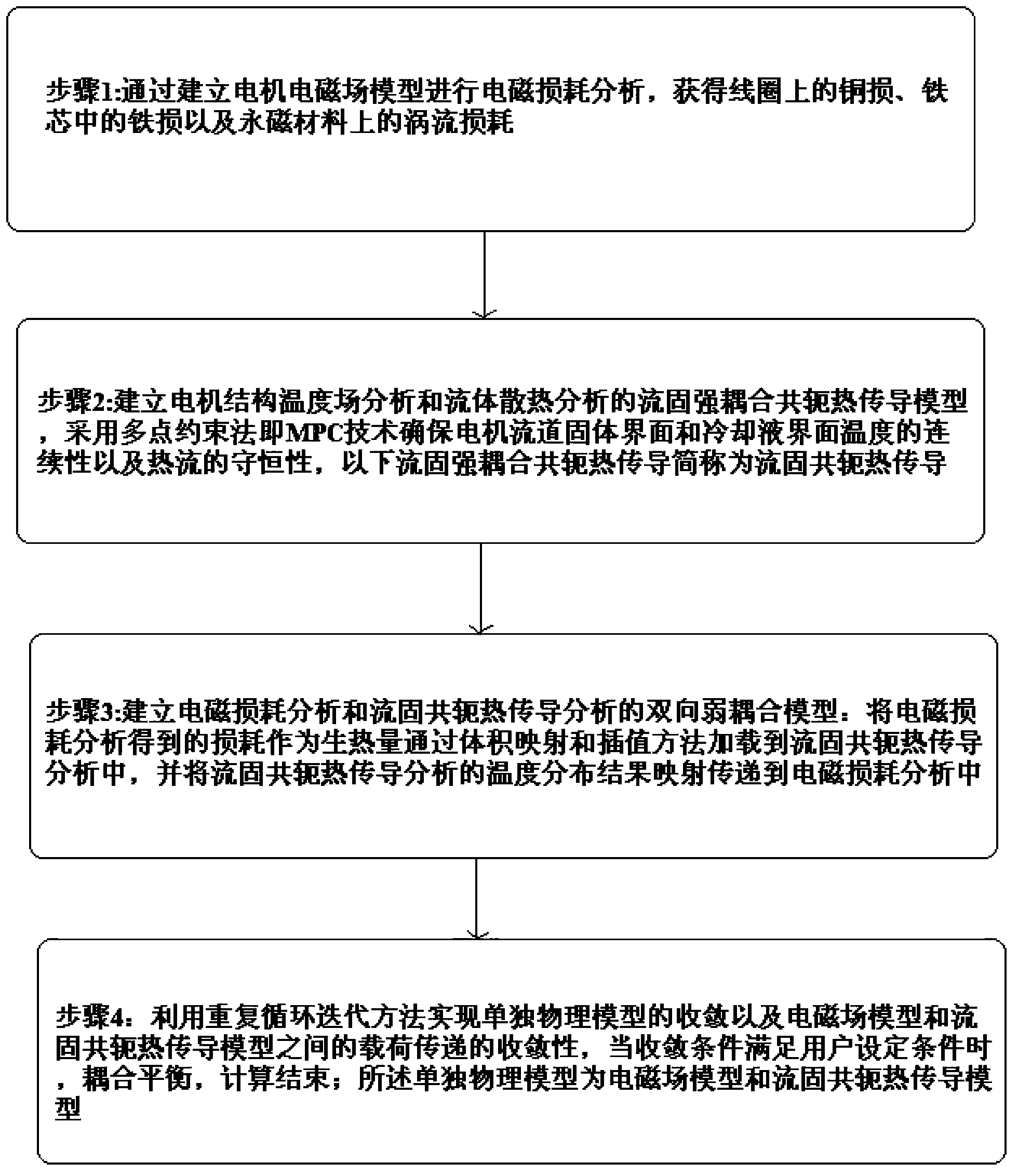

[0022] like figure 1 Shown, the present invention mainly involves steps as follows:

[0023] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com