Monitoring and warning circuit for leak tightness of electric actuator

An electric actuator, monitoring and alarming technology, applied in the direction of alarms, instruments, etc., can solve the problems of damage to electrical control parts, neglect of sealing leakage monitoring and monitoring, and reliability obstacles to the use of sealed electric actuators. Adaptability, high precision, damage-avoiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

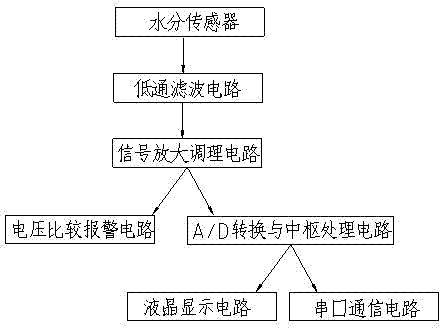

[0020] refer to figure 1, an electric actuator seal monitoring and alarm circuit, including a low-pass filter circuit, a signal amplification conditioning circuit, A / D conversion and central processing circuit, a liquid crystal display circuit, a serial communication circuit and a voltage comparison alarm circuit, the moisture sensor passes through the The low-pass filter circuit and the signal amplification and conditioning circuit are respectively connected with the A / D conversion and central processing circuit and the voltage comparison alarm circuit, and the A / D conversion and central processing circuit are respectively connected with the liquid crystal display circuit and the serial port communication circuit.

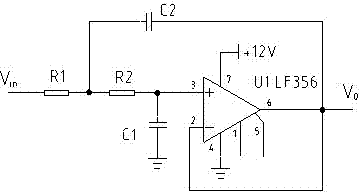

[0021] refer to figure 2 , the connection of the low-pass filter circuit is that pin 3 of the operational amplifier chip U1 is connected to capacitor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com