Production process for improving blind routing depth accuracy

A technology of depth accuracy and production process, which is applied in the electronic field, can solve the problems of inability to meet the depth accuracy requirements of blind fishing, increase equipment cost and production cost, and unstable process capability, so as to save equipment cost, low production cost, and process stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

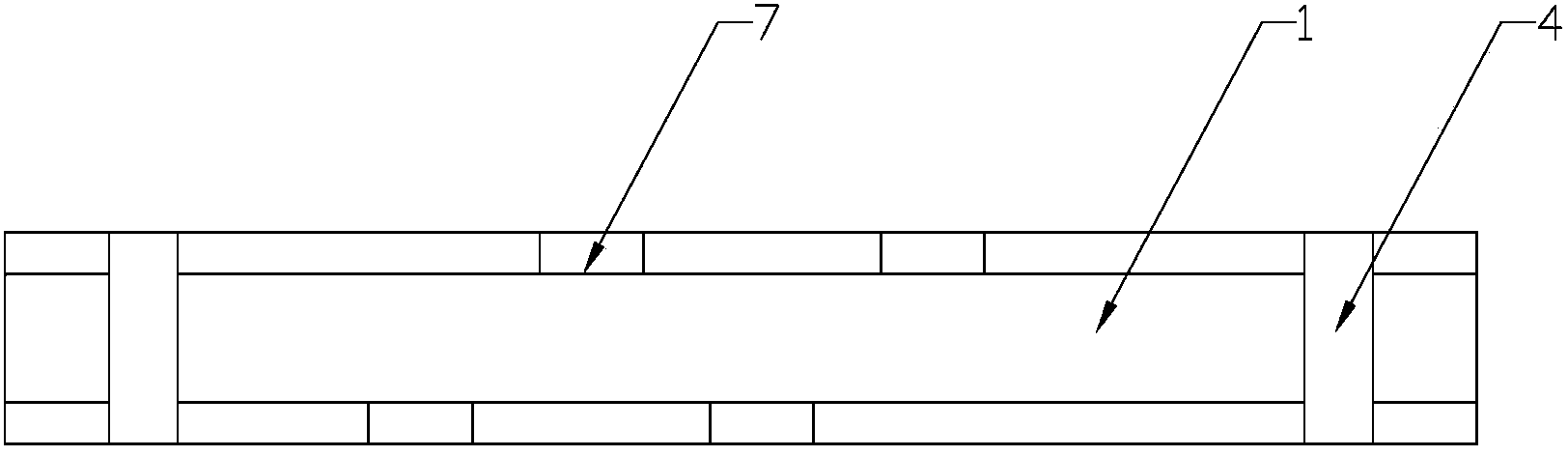

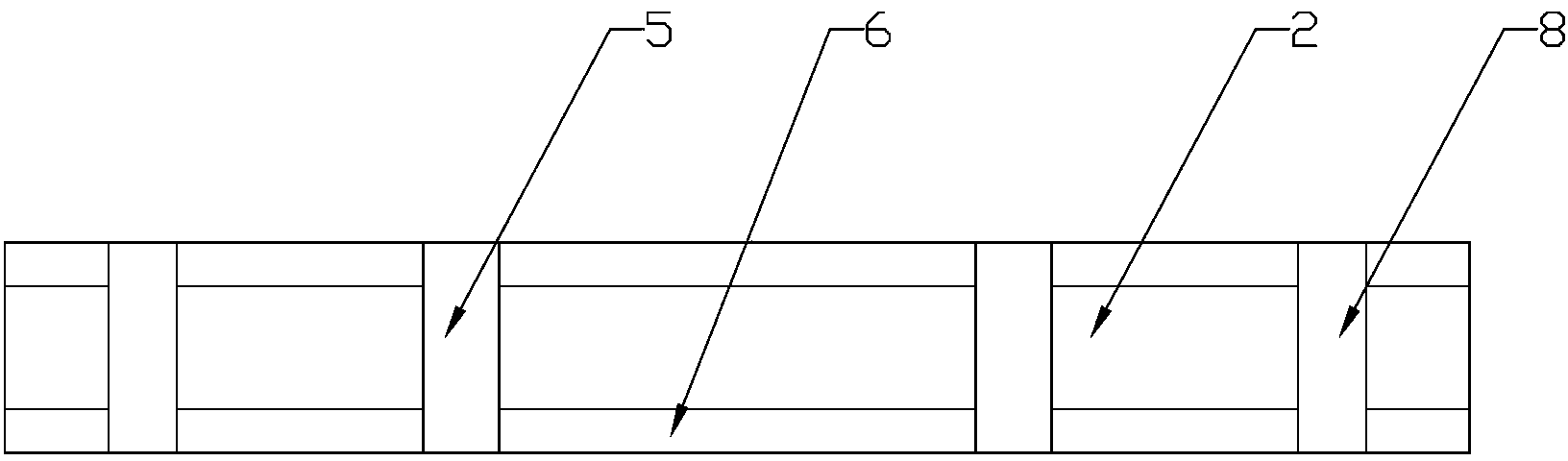

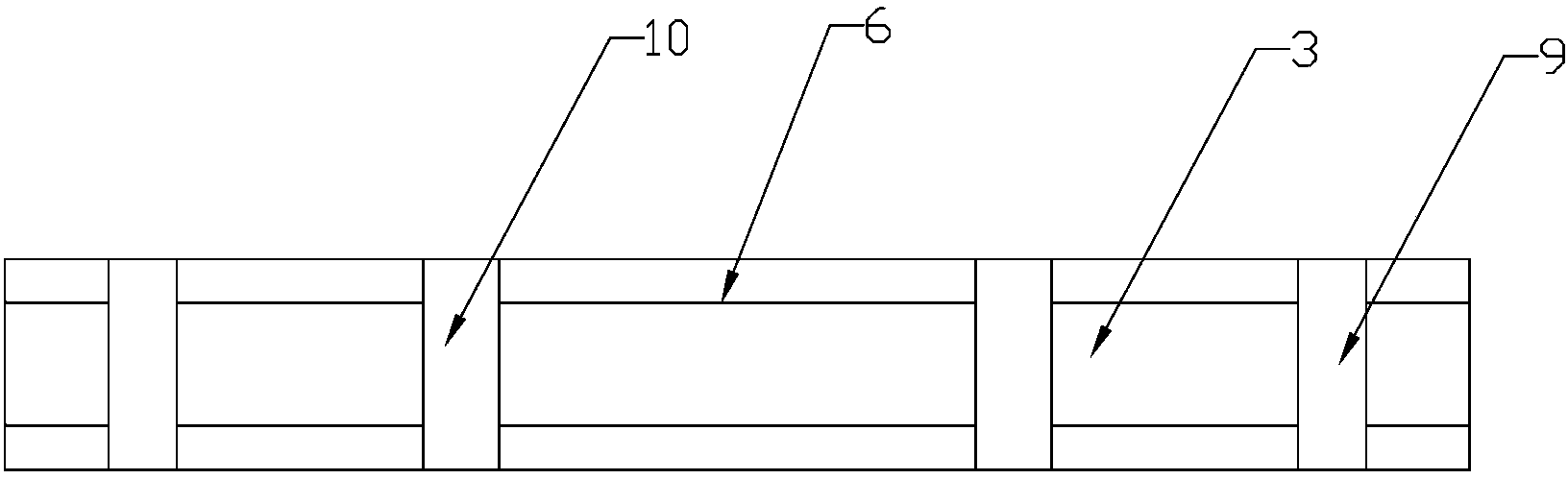

[0023] The present invention mainly includes the following steps: Figure 1~4 As shown, the first embodiment includes the following steps:

[0024] (1). First substrate etching: Drill a 3.175mm first positioning hole 4 on the first substrate 1 with a thickness of 1mm, and then perform an etching pattern 7 on the double copper foil surface, spray with acid etching solution, and purchase acid etching solution From Youyuan Chemical Co., Ltd., the model is cc-28, the composition of acid etching potion is: HC1 concentration is 1.2mol / l, NaCIO 3 The concentration is 15g / l, C U 2+ The concentration is 95g / l, the acid etching solution is water, the etching temperature is 45°C, the spray pressure is 1.4kg / c㎡, and the speed is 3m / min;

[0025] (2) Second and third substrate etching: etching the copper foil on one side of the second substrate 2 and the third substrate 3, remove the copper foil on one side of the second substrate 2 and the third substrate 3, and spray with acid etching solutio...

Embodiment 2

[0031] The second embodiment includes the following steps:

[0032] (1). First substrate etching: Drill a 3.175mm first positioning hole 4 on the first substrate 1 with a thickness of 2mm, and then perform pattern etching on the double copper foil surface, spray with acid etching solution, which is purchased from Youyuan Chemical Co., Ltd., model cc-28, composition of acid etching potion: HC1 concentration of 1.6mol / l, NaCIO 3 The concentration is 33g / l, C U 2+ The concentration is 118g / l, the acid etching solution is water, the etching temperature is 50℃, the spray pressure is 2.2kg / c㎡, and the speed is 3m / min;

[0033] (2) Second and third substrate etching: etching the copper foil on one side of the second substrate 2 and the third substrate 3, remove the copper foil on one side of the second substrate 2 and the third substrate 3, and spray with acid etching solution , The acid etching potion becomes: HC1 concentration is 1.6mol / l, NaCIO 3 The concentration is 33g / l, C U 2+ The ...

Embodiment 3

[0039] The third embodiment includes the following steps:

[0040] (1). First substrate etching: Drill a 3.175mm first positioning hole 4 on the first substrate 1 with a thickness of 1.5mm, then perform pattern etching on the double copper foil surface, spray with acid etching solution, and purchase acid etching solution From Youyuan Chemical Co., Ltd., the model is cc-28, the composition of the acid etching potion is: HC1 concentration is 2mol / l, NaCIO 3 The concentration is 50g / l, C U 2+ The concentration is 140g / l, the rest of the acid etching solution is water, the etching temperature is 55°C, the spray pressure is 3kg / c㎡, and the speed is 3m / min;

[0041] (2) Second and third substrate etching: etching the copper foil on one side of the second substrate 2 and the third substrate 3, remove the copper foil on one side of the second substrate 2 and the third substrate 3, and spray with acid etching solution , The acid etching potion becomes: HC1 concentration is 2mol / l, NaCIO 3 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com