Low-emission gasoline grass pruning machine with carburetor realizing throat gap atomization

A carburetor, low-emission technology, used in carburetors, machines/engines, cylinders, etc., to solve problems such as excessive hydrocarbon emissions and poor fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

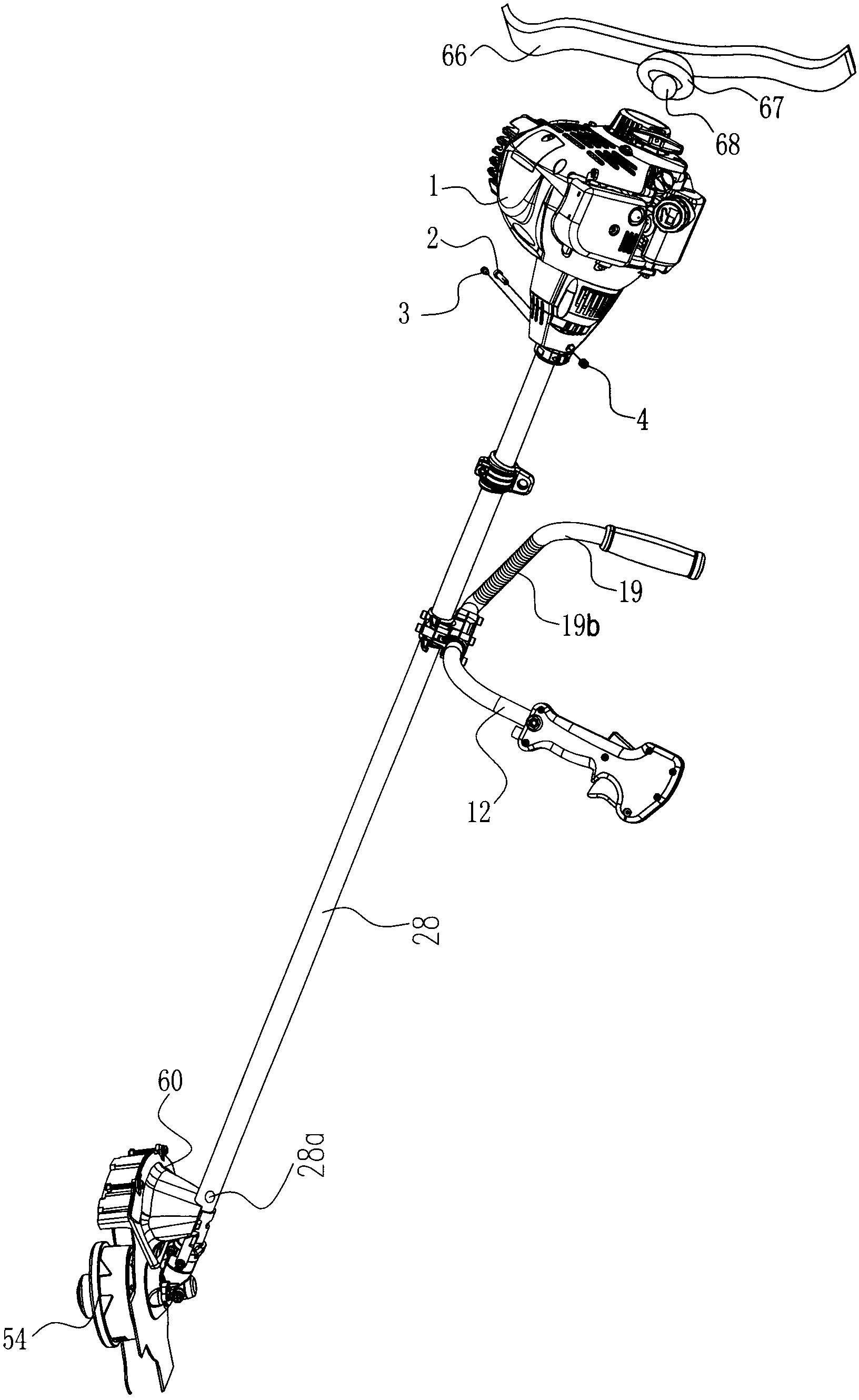

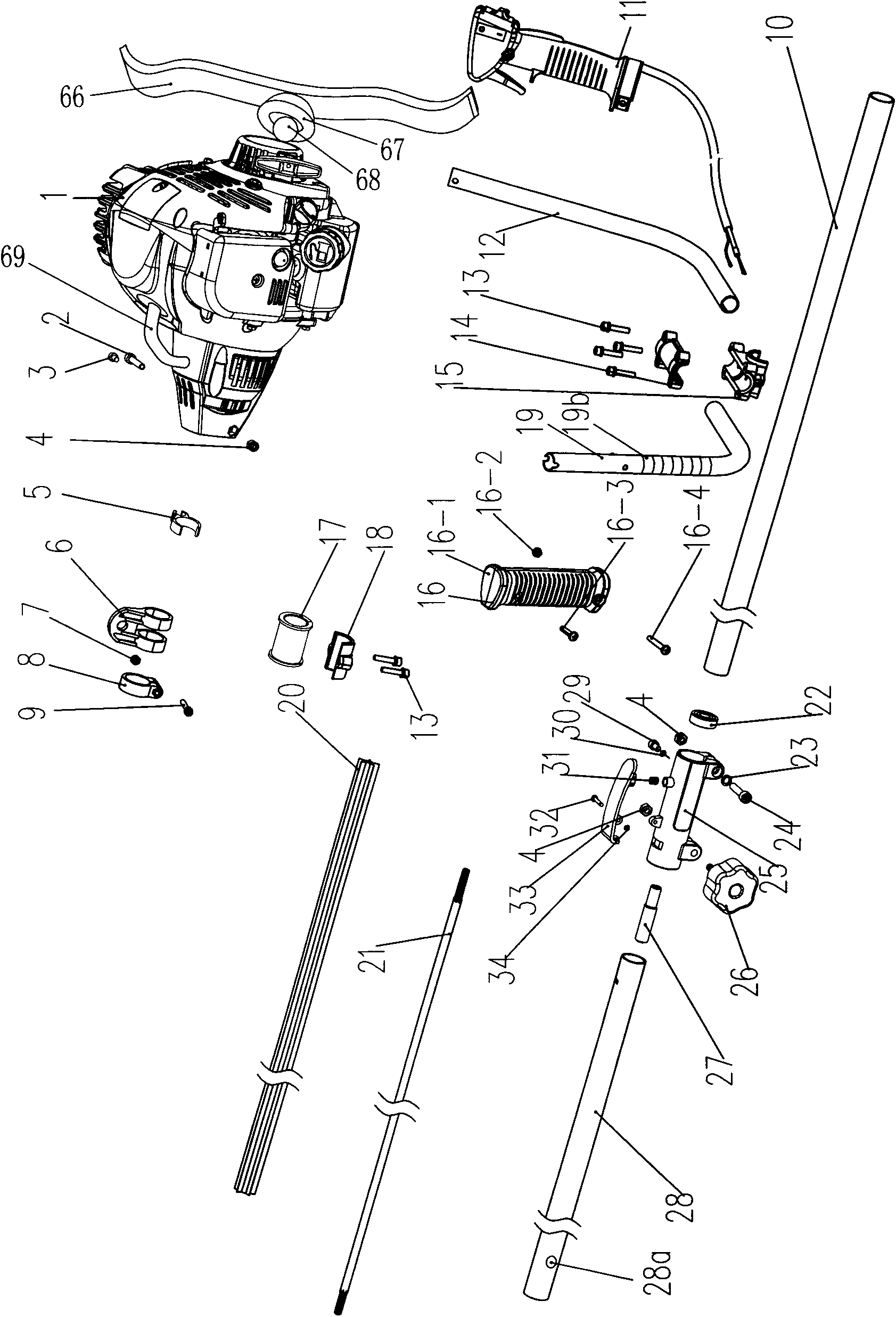

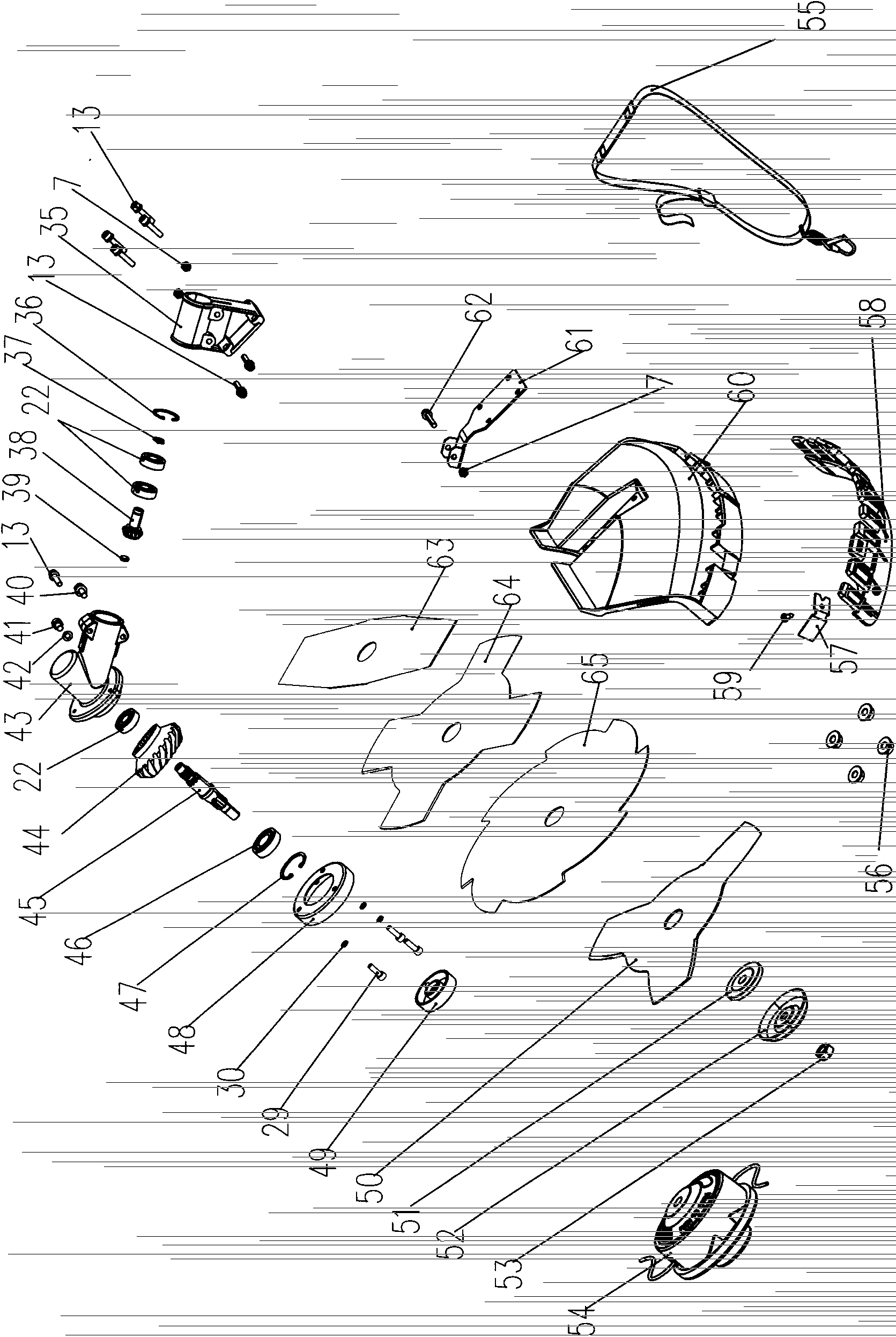

[0041] In order to make up for the slight shaking of the main rod caused by the existing mechanism of the brush cutter and grass cutter, an improved long main aluminum rod for the brush cutter provided by the present invention is loaded into the machine as a catenase muffler pipe, and used F41 screws are fastened; the exhaust gas is passed through the muffler assembly and the catalase muffler pipe 69, and then through the long main aluminum rod, and is discharged from the gap near the cutter at the end of the aluminum rod or the small hole gap.

[0042] According to customer requirements, there are four-stroke engines such as 139FA and two-stroke engines such as 1E34F for mowers. Using a two-stroke engine can increase the power per liter by more than 50% compared with a four-stroke engine, but measures must be taken in terms of emissions; the mower is a portable tool, and it is hoped that the power is light and small; if a four-stroke engine is used, the output is less; the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com