Electromagnetic deflection scanning coil for machining electron beam

A technology of electron beam processing and electromagnetic deflection, applied in electron beam welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of bulkiness, large coil size design, increase manufacturing cost, etc., and improve the deflection scanning frequency. , reduced size and weight, improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

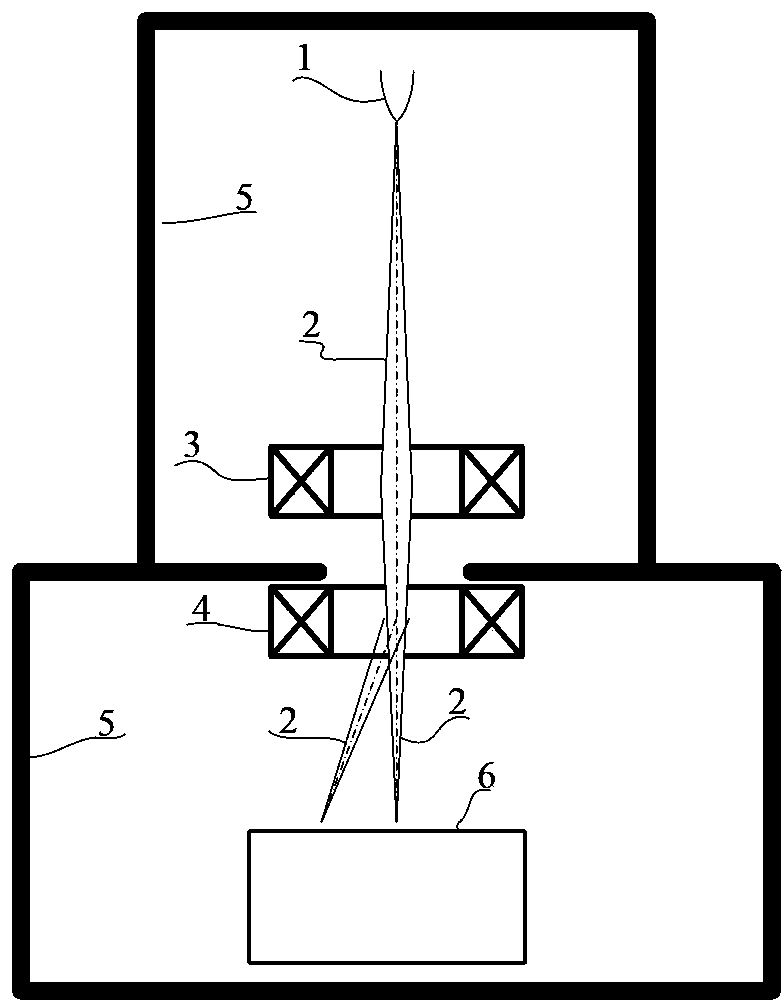

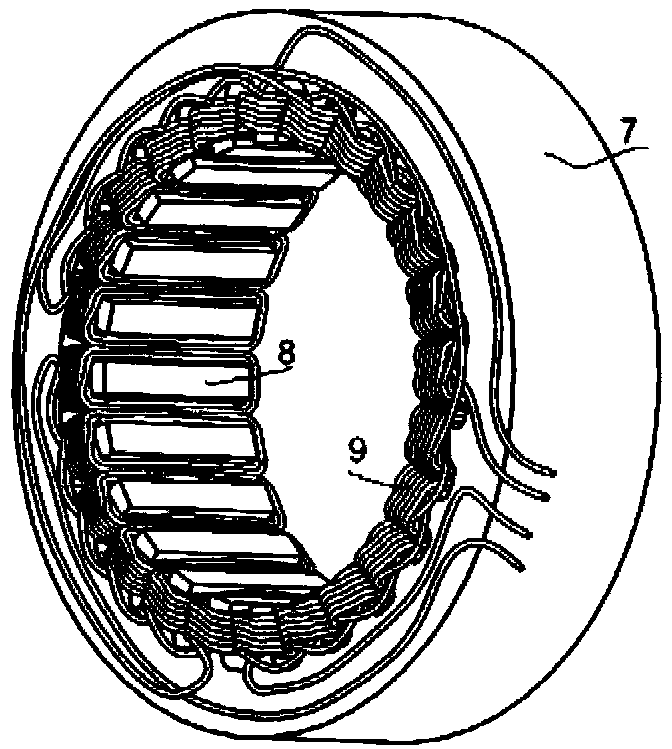

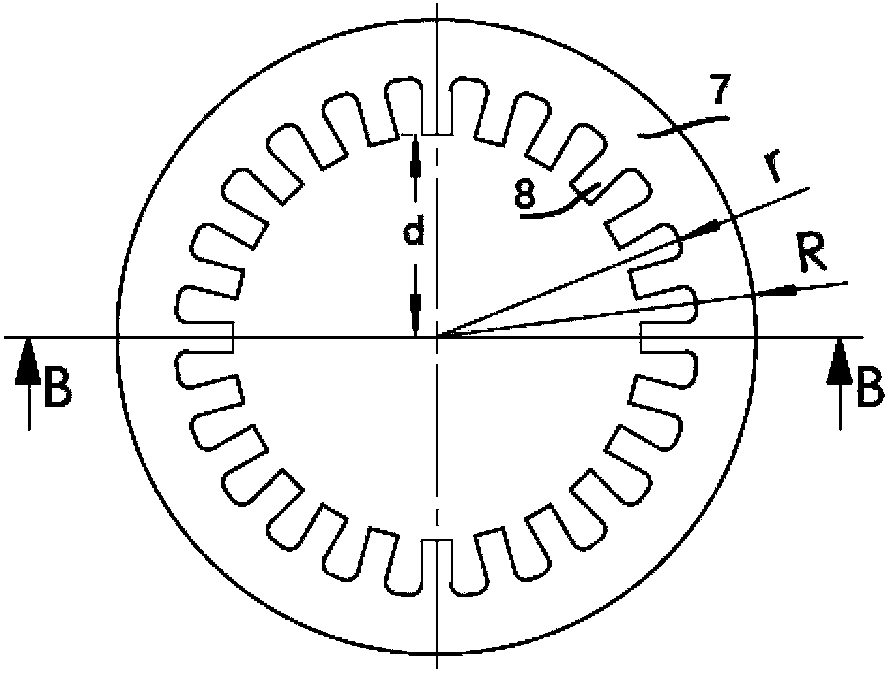

[0021] combine Figure 3~5 , designed an electromagnetic deflection scanning coil for electron beam processing, the specific structural parameters are: see image 3 , the number of magnetic poles 8 is 4N=24 (N=6), the outer diameter R of the magnetic ring 7 of the magnetic core frame is 110mm, the inner diameter r of the magnetic ring 7 is 90mm, and the distance between each magnetic pole surface and the outer center of the magnetic ring 7 The distance d is 35mm, combined with Figure 4 , the height h of the magnetic core skeleton is 30mm, and the entire magnetic core skeleton is pressed and formed by iron-based amorphous material.

[0022] Electron beam processing equipment chooses electron beam welding machine of model ZD150-15A, which is provided by Beijing Aeronautical Manufacturing Engineering Research Institute. The maximum accelerating voltage of the welding machine is 150kV, and the maximum beam current intensity is 100mA. For the workpiece welding working distance c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com