Method for drying small-diameter cylindrical raw wood

A cylindrical and small-diameter technology, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of large proportion of juvenile wood, small tree diameter class, short rotation period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

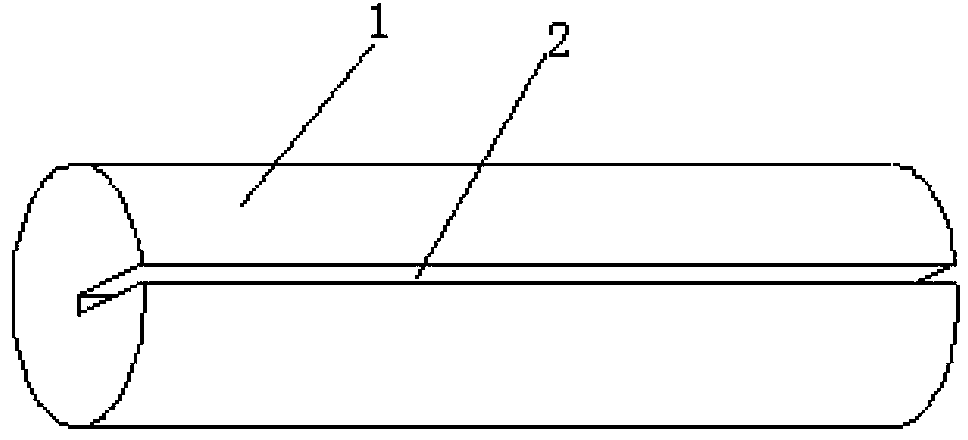

[0015] Referring to the accompanying drawings, a method for drying small-diameter cylindrical materials specifically includes the following steps:

[0016] The test material is a cylindrical wood section with a length of 80 cm and a diameter of about 20 cm. Without peeling, a notch is made along the pith center to the side skin. The width of the notch is generally ≤3mm. Both ends of the log section are sealed with glass glue , and put it into a drying kiln for drying treatment, which is specifically divided into the following steps:

[0017] a. Preheating

[0018] The preheating temperature is 66°C, and the preheating time is 8 to 10 hours to ensure that the cylindrical material is thoroughly heated during the preheating stage;

[0019] b. Intermediate processing

[0020] Depending on the degree of end cracking, it is determined whether to carry out spray steaming treatment, the number of spray steaming treatments, the state of the medium and the treatment time. Generally, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com