A material vacuum conveying system and its application method

A conveying system and material technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of unstable operation, high energy consumption of conveying pumps, poor material adaptability, etc., to improve efficiency, improve social benefits and Economic benefits and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The material vacuum conveying system described in this patent can automatically complete the vacuum suction of the material from the silo, and then transport it to the destination. The two-phase materials are separated and conveyed separately.

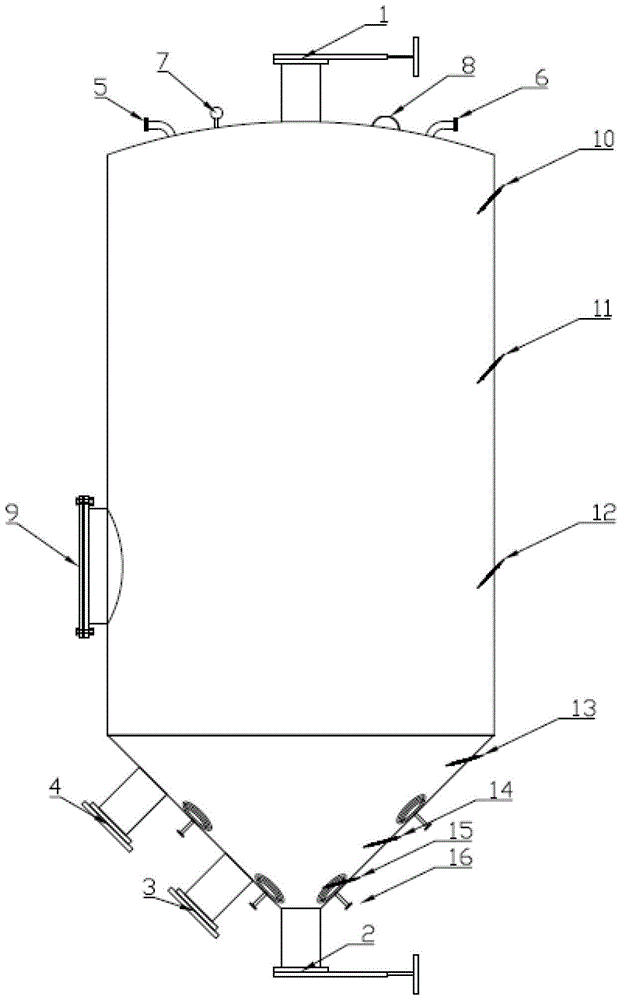

[0030] refer to figure 1 As shown, the present invention provides a material vacuum conveying system, including a control system, a discharge tank, a vacuum pump and an air compressor. Valves controlled by the control system are arranged at the feed port, and the vacuum pump and the air compressor are respectively connected with the discharge tank, and valves controlled by the control system are arranged at the connection.

[0031] There are preferably two feed ports, located at the upper end and the lower end of the discharge tank respectively, and the two feed ports 1 and 2 can be opened simultaneously, or only one of them can be opened according to requirements.

[0032] The top of the discharge tank is provided with a pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com