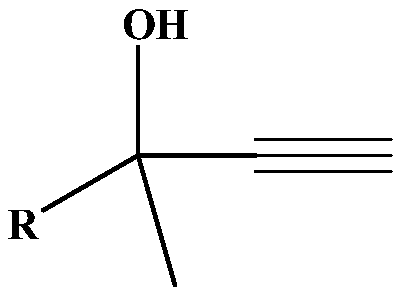

A kind of preparation method of acetylenic alcohol

A technology of acetylenic alcohol and acetylene, which is applied in the field of base-catalyzed preparation of acetylenic alcohol, which can solve the problems of affecting product quality and no addition of polymerization inhibitors, and achieve the effects of avoiding polymerization side reactions, shortening reaction time, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Under nitrogen protection, add 1.6g PGMA / SiO to a 5L autoclave 2 -TEMPO, then add 798.5g of methyl heptanone and 3.1g of KOH (45wt% solution), and then feed 2.15kg of liquid ammonia into the reaction kettle. The mixture was cooled to 15°C. Then feed 166.8g of acetylene into the autoclave, and control the pressure of the reactor to be 12bar. After reacting for 3.3 hours, carry out solid-liquid separation by filter, then add 25g90% (mass fraction) aqueous acetic acid solution in liquid phase, release pressure, wherein most of ammonia is evaporated, be heated to 40 ℃, remove remaining ammonia. Subsequently, the reaction mixture was washed twice with 250 mL of deionized water, twice with 250 mL of 8% (mass fraction) sulfuric acid aqueous solution, and then twice with 250 mL of deionized water to obtain a colorless transparent liquid.

[0039]The solid phase was applied 7 times, the average conversion rate was 99.3%, the average yield before washing was 98%, the average yi...

Embodiment 2~5

[0047] Experiments were carried out according to the operating conditions in Table 2, and the unlisted conditions were the same as in Example 1, and the yields and selectivities were shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com