An environment-friendly straw oxygen pressure fermentation treatment process

An environment-friendly, straw-based technology, applied in fermentation, biomass pretreatment, waste fuel, etc., can solve the problems of reducing the work efficiency of barbaric oxygen fermentation, waste of human resources, waste of resources, etc., to achieve reuse, increase degradation speed, The effect of preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

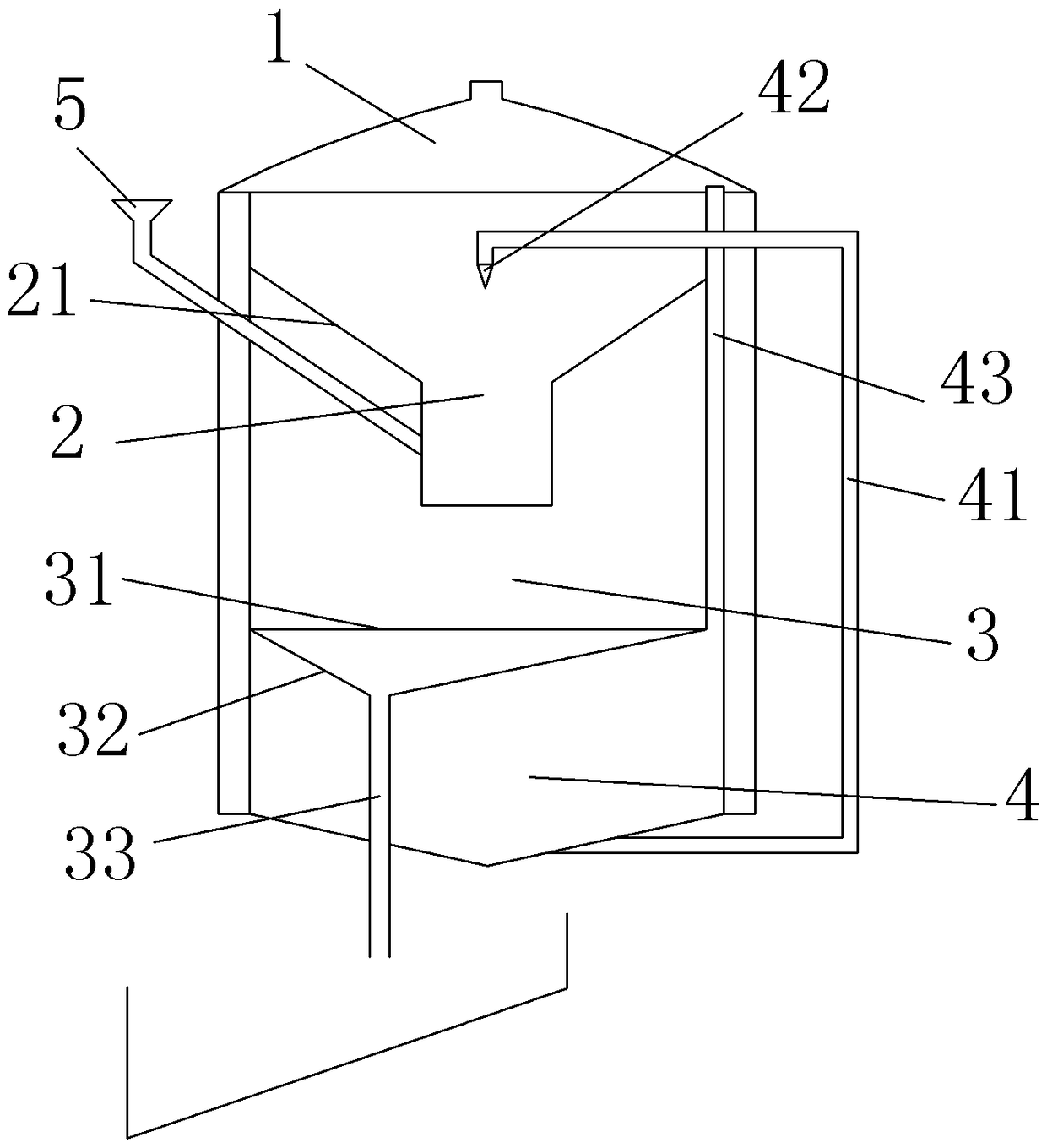

[0018] The reference signs in the drawings of the description include: gas storage area 1, pretreatment area 2, first filter plate 21, solid phase fermentation area 3, second filter plate 31, second filter screen 32, slag guide pipe 33, liquid Phase fermentation zone 4, liquid return pipe 41, high-pressure atomizing nozzle 42, air guide pipe 43, feed hopper 5.

[0019] The device to realize this process scheme is as figure 1 Shown: Including the fermenter body, the fermenter body is divided into four areas from top to bottom, which are gas storage area 1, pretreatment area 2, solid phase fermentation area 3 and liquid phase fermentation area 4, and gas storage area An exhaust valve is provided on the upper side of zone 1, and an air duct 43 connecting the gas storage area 1 and the liquid phase fermentation area 4 is provided on the right side of the gas storage area 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com