A pure chlorine dioxide gas-liquid automatic separation preparation device and preparation method

A chlorine dioxide, automatic separation technology, applied in the direction of chlorine dioxide, etc., can solve the problems of low purity and yield of chlorine dioxide, water pollution, raw material conversion rate and different chlorine dioxide yield and purity, etc., to improve the yield , Eliminate the effect of excessive chlorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

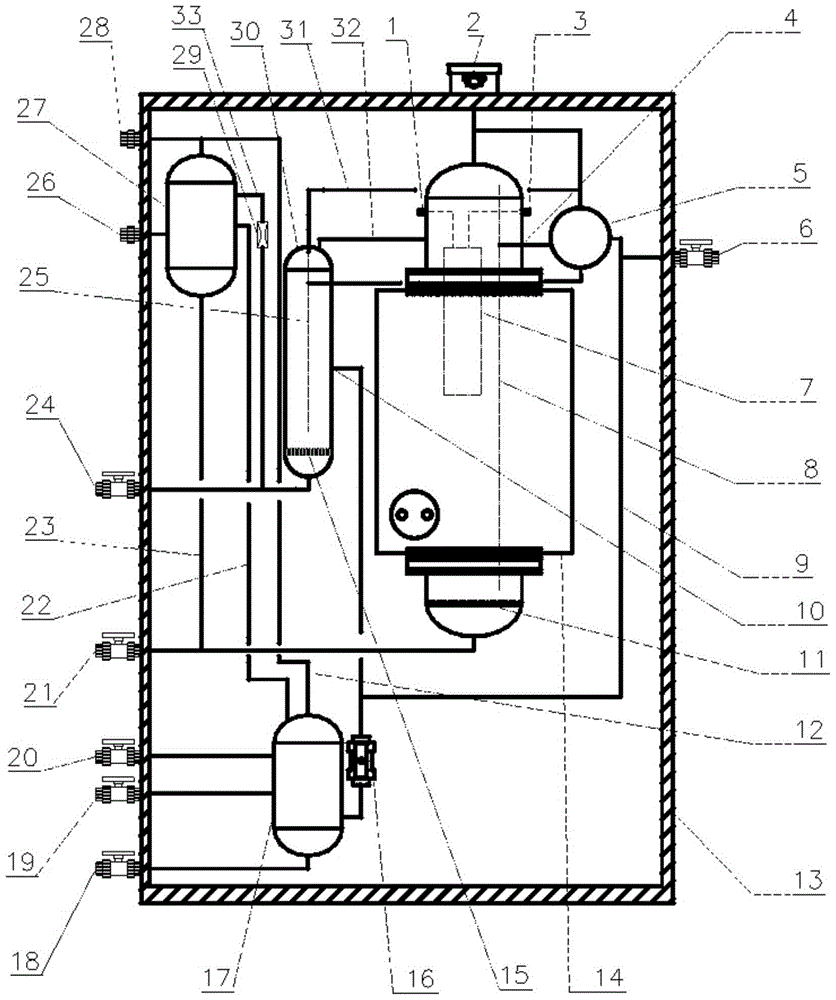

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] A pure chlorine dioxide preparation device with automatic gas-liquid separation, comprising: a housing 13, a feed system, a reaction system, an aeration system, a gas-liquid separation system, a secondary gas stripping system, and a mother liquor collection system;

[0028] Described feeding system comprises the sodium chlorate hydrogen peroxide mixed liquor raw material inlet 1 and the dilute sulfuric acid solution raw material inlet 3 that are located at reactor 14 tops;

[0029] Described reaction system comprises reactor 14, is positioned at the pre-reaction chamber 7 of reactor 14 tops, the reactor inserting pipe 8 that is connected with gas-liquid separator 5 at reactor 14 tops, communicates with the reactor blowdown of reactor 14 bottoms Valve 21 for heating the jacket of the reactor;

[0030] Described aeration system comprises buffer tank 27, communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com