Method for extracting taxane active ingredients from Chinese yew efficiently

A technology for taxanes and active ingredients, applied in chemical instruments and methods, organic chemistry, preparation of sugar derivatives, etc., can solve the problems of consumption of organic solvents, high safety, hidden dangers of environmental protection, low extraction yield, etc. The amount of organic solvent used, the effect of reducing the cost of separation and purification, and reducing the difficulty of separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

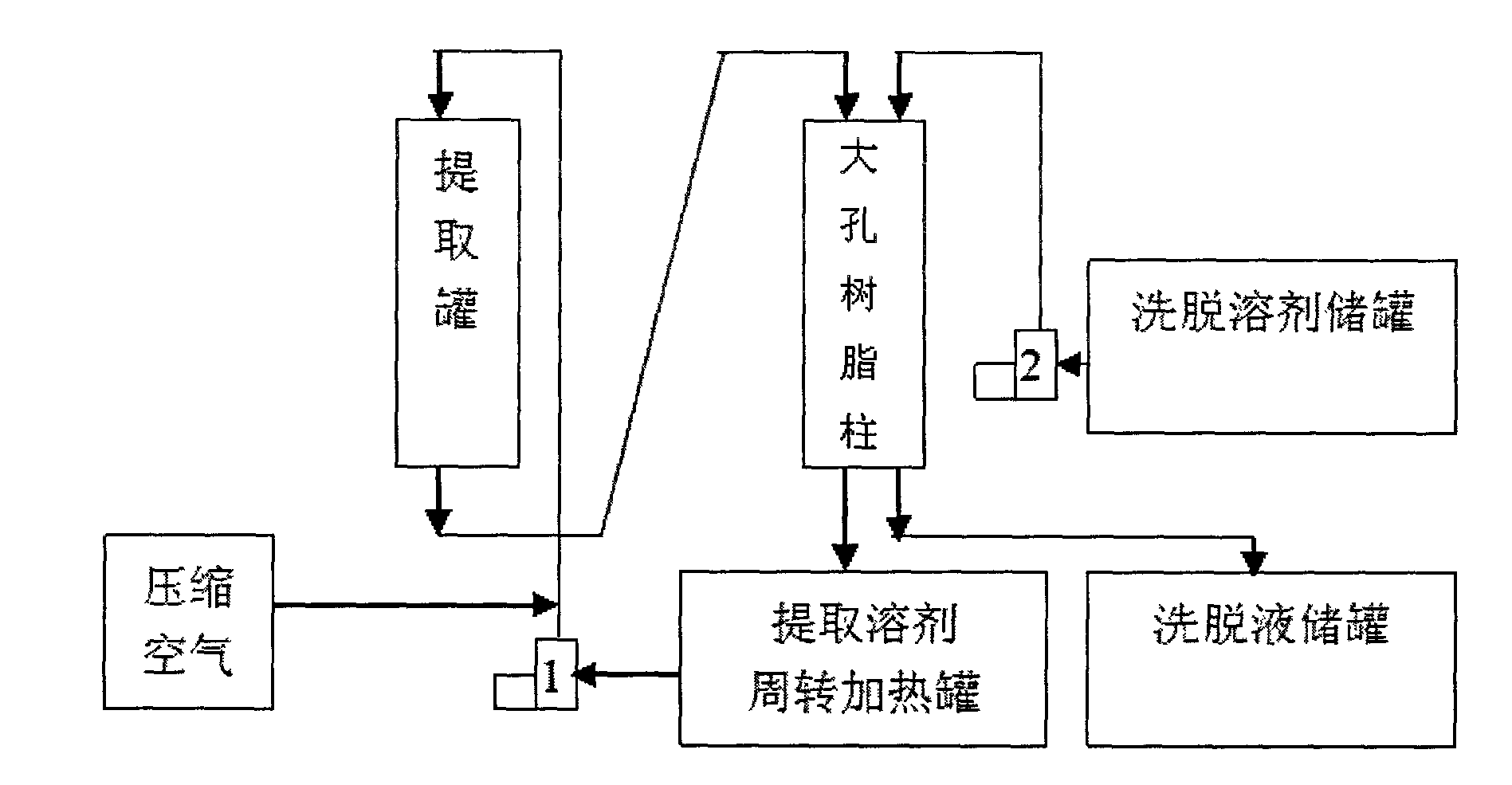

[0020] Case 1: ① Set up the experimental device according to the accompanying drawings in the instruction manual, add 500 g of fresh branches and leaves of Taxus chinensis (three-year-old) into the extraction container (10-DABIII content 0.01%, paclitaxel content 0.004%, 7-xylosyl paclitaxel content 0, tricuspid mannine content 0.001%), add 200g of macroporous resin in the resin column, add 5 liters of 0.2% formic acid aqueous solution in the extraction solvent turnover heating tank, the extraction solvent temperature is controlled at 30~60 ℃, circulation extracts 24 hours, washes with methanol 1000ml Removing the resin column, extracting and concentrating the eluate after concentrating and recovering methanol to obtain extractum 0.96g, HPLC assay extractum (10-DABIII content 5.21%, paclitaxel content 0, 7-xylosyl paclitaxel content 0, cephalomannine content 0%) 10-DABIII extraction yield 99.8%.

[0021] ② Replace the extraction solvent with (50%) methanol aqueous solution to ...

Embodiment 2

[0023] ① Build the experimental device according to the accompanying drawings in the instruction manual, add 500 g of dried branches and leaves of Taxus chinensis (three-year-old) (10-DABIII content 0.025%, paclitaxel content 0.008%, 7-xylosyl paclitaxel content 0, cephalomannine) into the extraction container Content 0.002%), add macroporous resin 200g in the resin column, add 5 liters of 0.5% acetic acid aqueous solution in the extraction solvent turnover, add 0.5% acetic acid aqueous solution in the tank, control the temperature of the extraction solvent at 30~60 ℃, circulate and extract for 24 hours, use methanol 1000ml to elute the resin column After the eluate was concentrated and recovered methanol, it was extracted and concentrated to obtain 2.5g of extractum, which was determined by HPLC (10-DABIII content 5%, paclitaxel content 0, 7-xylosyl paclitaxel content 0, cephalomannine content 0%) The extraction yield of 10-DABIII was 100%.

[0024] ② Replace the extraction s...

Embodiment 3

[0026] ① Build the experimental device according to the accompanying drawings in the instruction manual, add 500 g of southern yew bark (ten years old) (0.01% of 10-DABIII content, 0.02% of paclitaxel content, 0.05% of 7-xylosyl paclitaxel content, Alkali content 0.002%), add 200g of macroporous resin in the resin column, add 5 liters of 0.5% formic acid aqueous solution in the extraction solvent turnover adding tank, the extraction solvent temperature is controlled at 30~60 ℃, circulation extracts 16 hours, elutes resin with 1000ml of methanol column, the eluate is concentrated and recovered after methanol is extracted and concentrated to obtain 0.98g of extract, which is determined by HPLC (10-DABIII content 5.1%, paclitaxel content 0, 7-xylosyl paclitaxel content 25.5%, cephalomannine content 0 %) 10-DABIII extraction yield 100%, 7-xylosyl paclitaxel extraction yield 100%.

[0027]② Replace the extraction solvent with (60%) ethanol aqueous solution to extract the slag after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com