Method for measuring martensite content in heat rolling dual-phase steel

A hot-rolled dual-phase steel and martensite technology, which is used in measuring devices, preparation of test samples, and material analysis by optical means, can solve the problems of insufficient contrast and inability to accurately extract the objects to be tested. Achieve the effect of increasing contrast, avoiding errors, and accurately measuring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

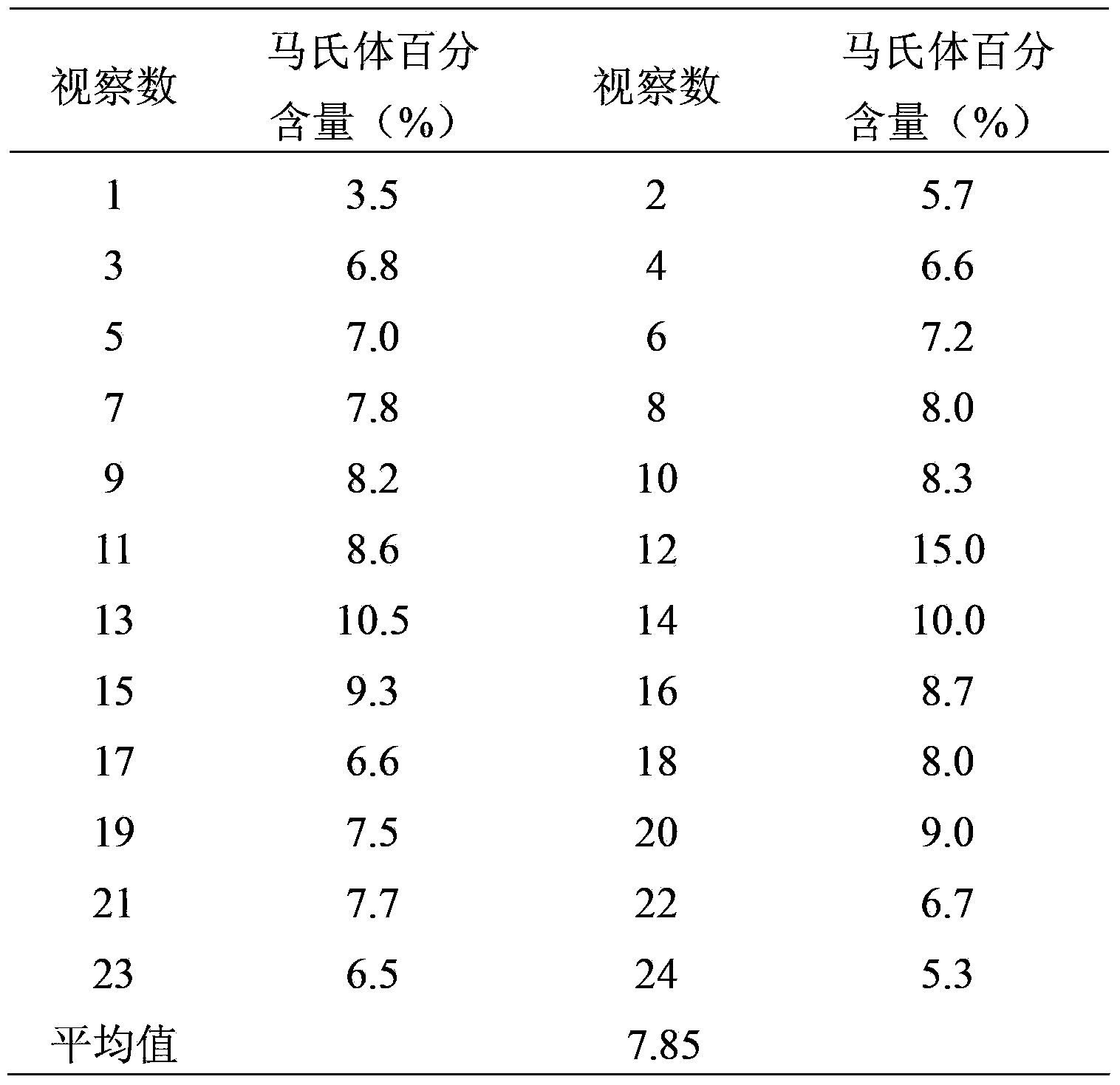

example 1

[0021] The DP600 hot-rolled steel plate is selected as the sample, and its chemical composition (by weight percentage) is: C: 0.06%, Si: 0.90%, Mn: 1.39%, P: 0.014%, S: 0.003%, Cr: 0.25%, Mo: 0.20% and the balance of iron and unavoidable impurities.

[0022] Follow the steps below to process the sample to be tested to reveal its metallographic structure.

[0023] Sample cutting: Cut off the edge deformation area of the sample by about 2mm on a precision cutting machine to obtain a sample to be tested with a specification of 20mm×15mm.

[0024] Specimen Mounting: Cold mount the specimen with a mixed solution of epoxy resin and ethylenediamine.

[0025] Sample preparation: The above sample is coarsely ground and finely polished, and then the sample to be tested is placed in a mixture of 1wt% sodium metabisulfite aqueous solution and 4.2wt% trinitrophenol alcohol solution according to the volume ratio of 1:1. The mixed solution was corroded for about 40s at room temperature, ...

example 2

[0031] The DP600 hot-rolled steel plate is selected as the sample, and its chemical composition (by weight percentage) is: C: 0.06%, Si: 0.90%, Mn: 1.39%, P: 0.014%, S: 0.003%, Cr: 0.25%, Mo: 0.20% and the balance of iron and unavoidable impurities.

[0032] Follow the steps below to process the sample to be tested to reveal its metallographic structure.

[0033] Sample cutting: Cut off the edge deformation area of the sample by about 2mm on a precision cutting machine to obtain a sample to be tested with a specification of 20mm×15mm.

[0034] Specimen Mounting: Cold mount the specimen with a mixed solution of epoxy resin and ethylenediamine.

[0035] Sample preparation: The above-mentioned sample is coarsely ground and finely ground and polished, and then the sample to be tested is placed in a mixture of 0.9wt% sodium metabisulfite aqueous solution and 4.2wt% trinitrophenol alcohol solution according to the volume ratio of 1:1. The resulting mixed solution was corroded fo...

example 3

[0041]The DP600 hot-rolled steel plate is selected as the sample, and its chemical composition (by weight percentage) is: C: 0.06%, Si: 0.90%, Mn: 1.39%, P: 0.014%, S: 0.003%, Cr: 0.25%, Mo: 0.20% and the balance of iron and unavoidable impurities.

[0042] Follow the steps below to process the sample to be tested to reveal its metallographic structure.

[0043] Sample cutting: Cut off the edge deformation area of the sample by about 2mm on a precision cutting machine to obtain a sample to be tested with a specification of 20mm×15mm.

[0044] Specimen inlay: clamp the sample to be tested with a jig.

[0045] Sample preparation: After the above sample is coarsely ground and finely ground and polished, then the sample to be tested is placed in a mixture of 1.3wt% sodium metabisulfite aqueous solution and 3.9wt% trinitrophenol alcohol solution according to the volume ratio of 1:1. The resulting mixed solution was corroded for 60s at room temperature, rinsed with running water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com