Photonic crystal fiber current magnetic field sensor and manufacturing and measuring method thereof

A photonic crystal optical fiber and magnetic field sensor technology, applied in the field of optoelectronics, can solve the problems of difficult optical communication network integration, large size and weight, easy to be susceptible to electromagnetic interference, etc., and achieve the effects of high light source disturbance immunity, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that the features of the present invention can be clearly demonstrated.

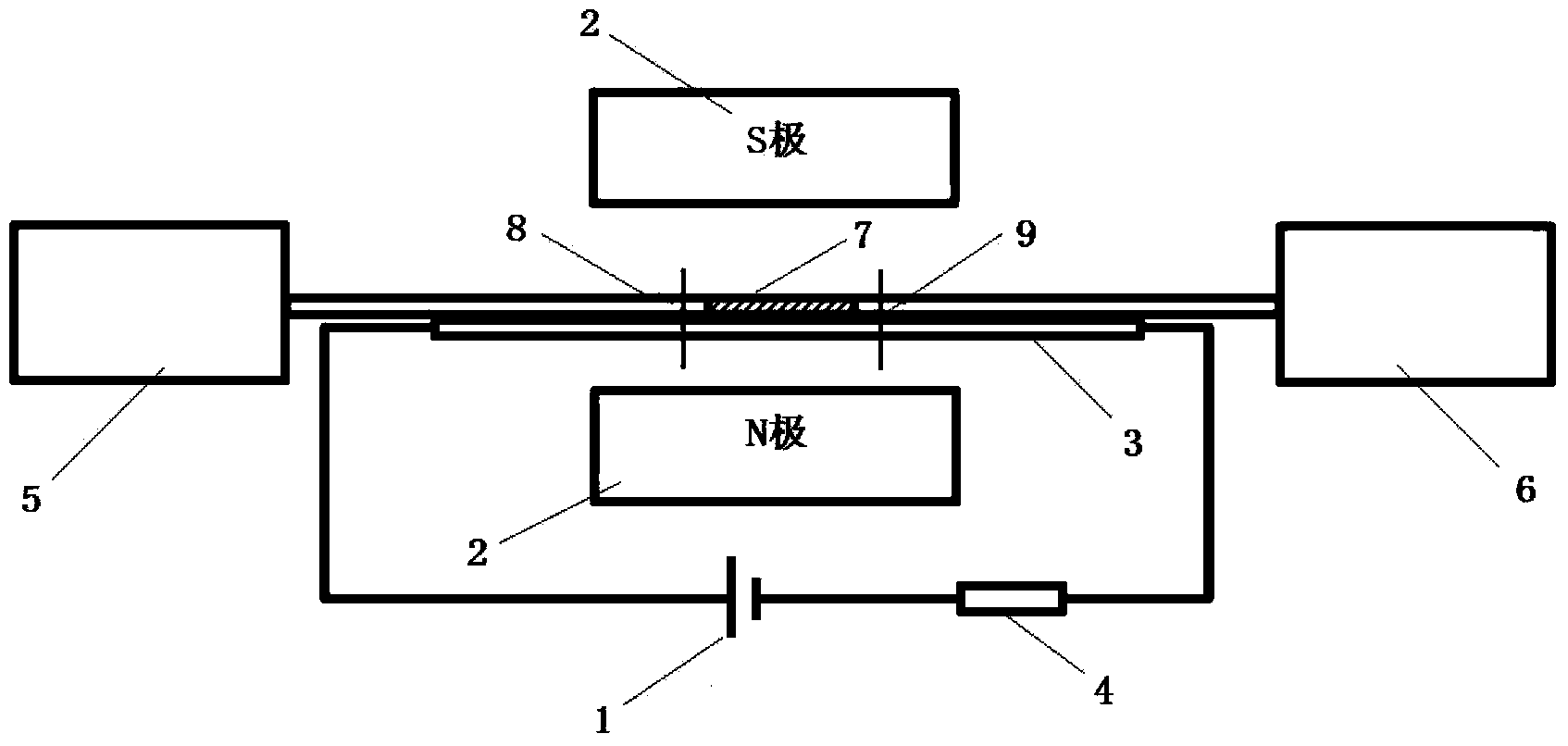

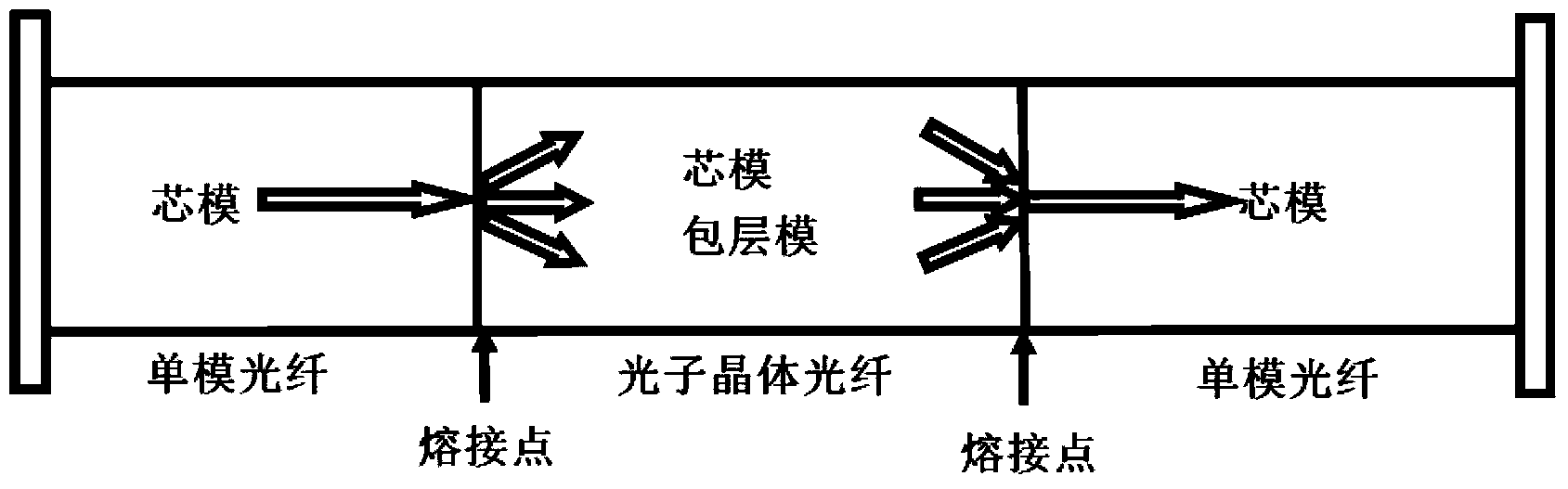

[0024] figure 1 It is a schematic diagram of a photonic crystal fiber current and magnetic field sensor, including: a DC power supply 1, an electromagnet 2, a control device, an electric wire 3, a resistor 4, a broadband light source 5, a spectrometer 6, an ordinary single-mode fiber, and the photonic crystal fiber current and magnetic field sensor; The DC power supply 1 is connected with the electric wire 3 and the resistor 4, the electromagnet 2 is connected with the control device, the broadband light source 5 is connected with the single-mode fiber at one end of the photonic crystal fiber-optic current magnetic field sensor through a common single-mode fiber, and the photonic crystal The single-mode optical fiber at the other end of the optical fiber current and magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com