Electric equipment abnormal heating detection method based on infrared inspection video data of power line inspection

A technology of power equipment and video data, applied in the field of infrared video image processing, can solve the problems of inability to extract the complete area of the object, discontinuity of power equipment, inapplicability, etc., and achieve the effect of avoiding possible influence, high degree of automation and high integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The theoretical basis of the method for detecting abnormal heating of electric power equipment based on infrared inspection video data of electric power inspection lines in the present invention is as follows:

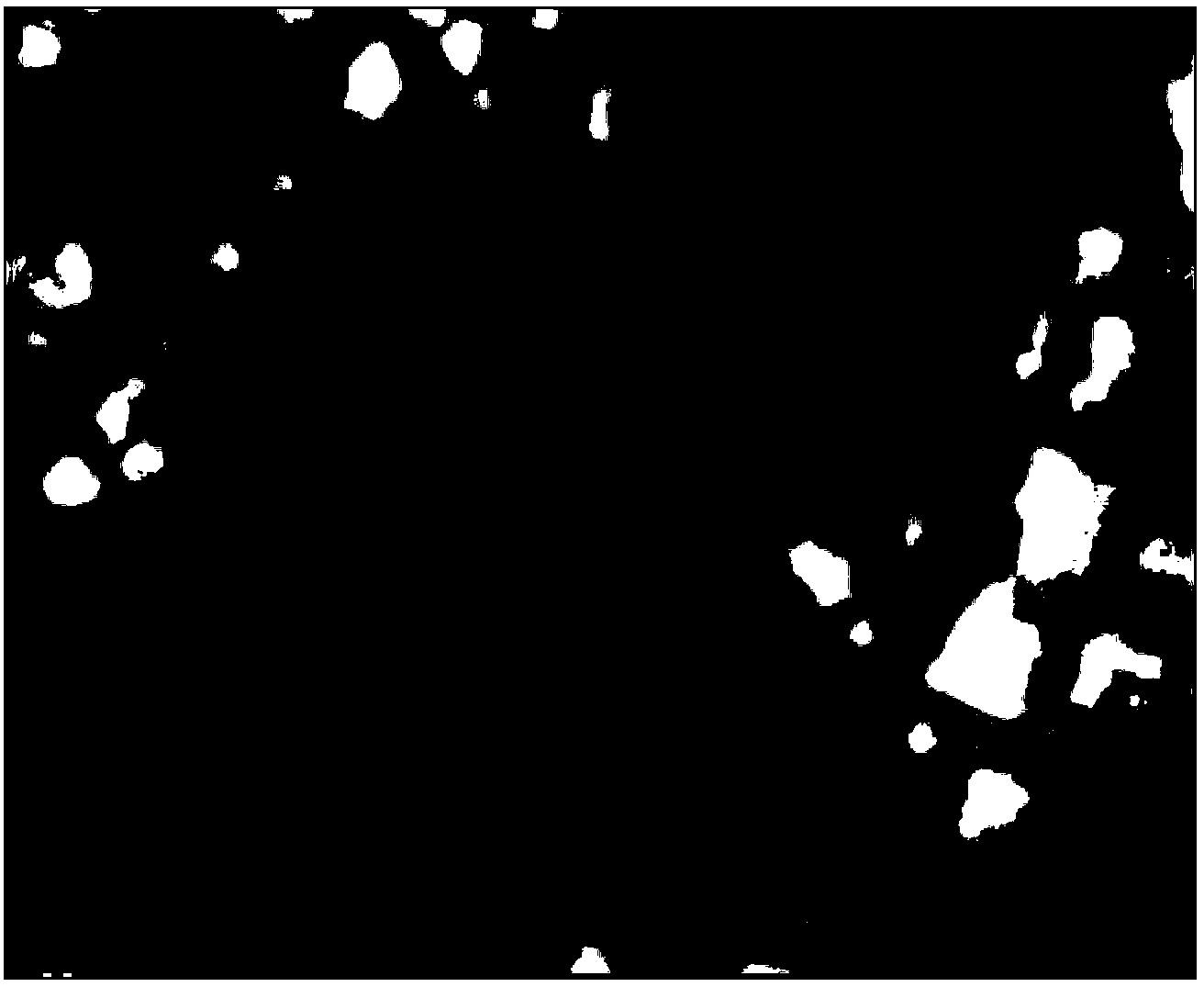

[0051] In the process of image stitching, a unified object-space coordinate system is established. Therefore, the background information of two adjacent frames is overlapped after splicing, but the information of electrical equipment is not completely overlapped because it is far away from the object space. Based on this, the inter-frame difference is performed on the basis of splicing, and the previous frame data is subtracted from the subsequent frame data from the overlapping area after splicing, so that most of the background information will be eliminated, but the transmission line information is still retained. down. The splicing method adopted is as follows: the scale-invariant feature of the image is extracted based on the SURF descriptor, and the matchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com