Drive motor used for electric vehicle

A technology for driving motors and electric vehicles, which is applied in the direction of electric vehicles, motors, electric components, etc. It can solve the problems of poor heat dissipation performance, reduced service life of driving motors, and difficulty in driving motors, achieving good heat dissipation performance, small footprint, Effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings:

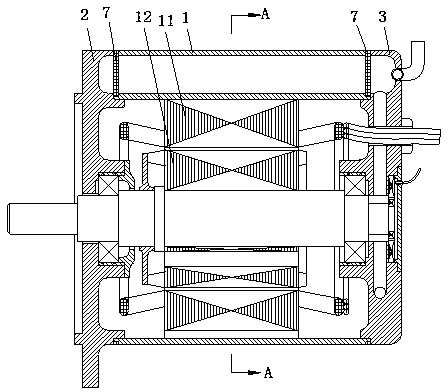

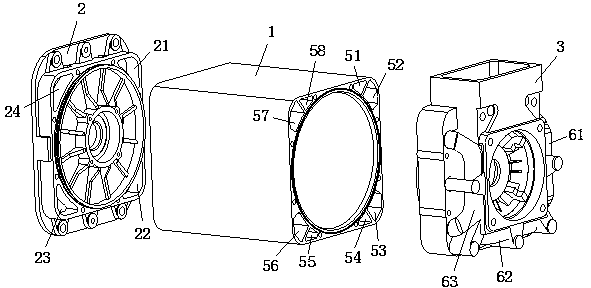

[0020] like figure 1 , figure 2 The shown drive motor for an electric vehicle includes a base 1 and front and rear end covers 2 and 3 matched with the base 1. The cooling circulation system and the water cooling circulation system circulating between the base 1, the front end cover 2 and the rear end cover 3.

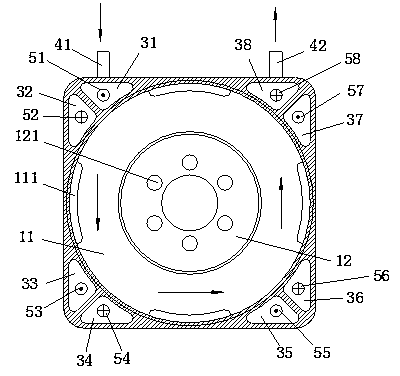

[0021] Further, a stator 11 and a rotor 12 are arranged inside the machine base 1, and the air-cooled circulation system includes a first ventilation hole 111 arranged on the stator 11 and a second ventilation hole 121 arranged on the rotor 12. The first ventilation hole 121 An air duct for circulating hot air is formed between the hole 111 and the second ventilation hole 121 .

[0022] Further, the cross section of the machine base 1 is square, and the front end cover 2 and the rear end cover 3 are also square. The groove, the rear groove arranged on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com