A negative high voltage direct current integrated power supply for x-ray tube and its control method

An X-ray tube and negative high voltage technology, applied in the field of negative high voltage DC integrated power supply and its control, can solve the problems that the PID algorithm cannot continue to play a control role, poor robustness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

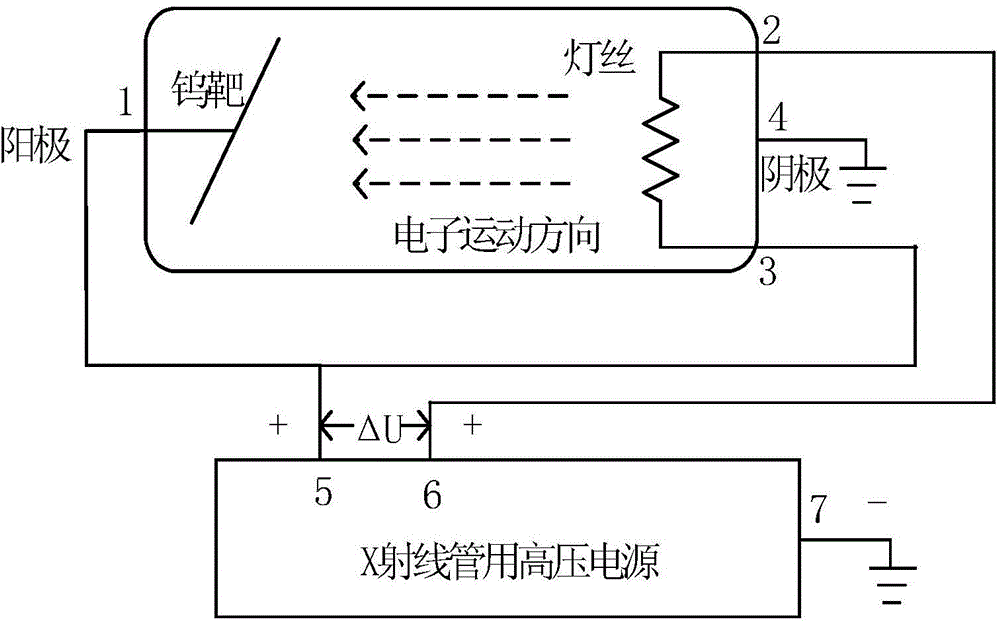

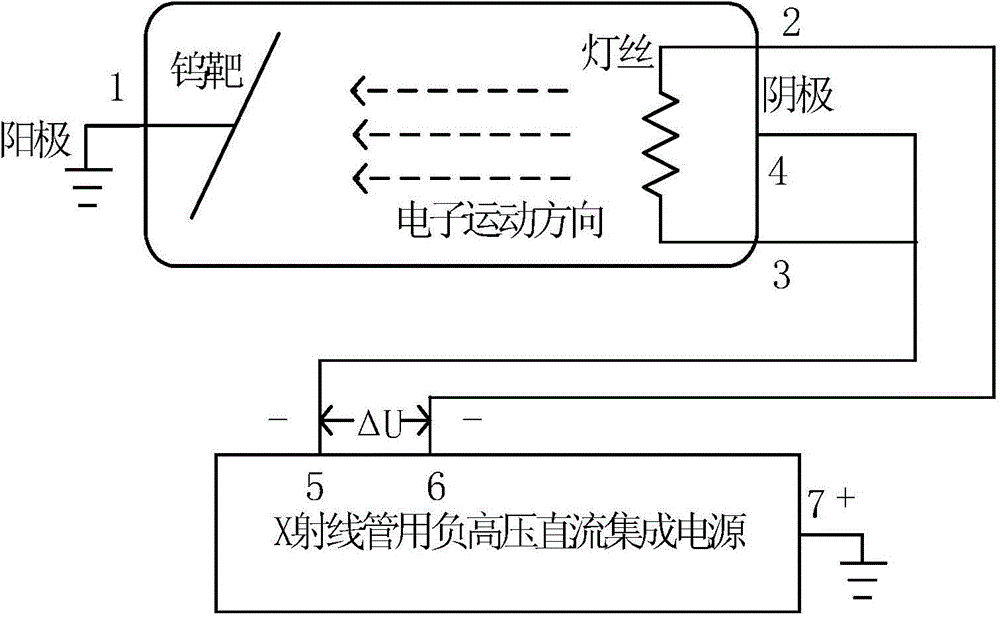

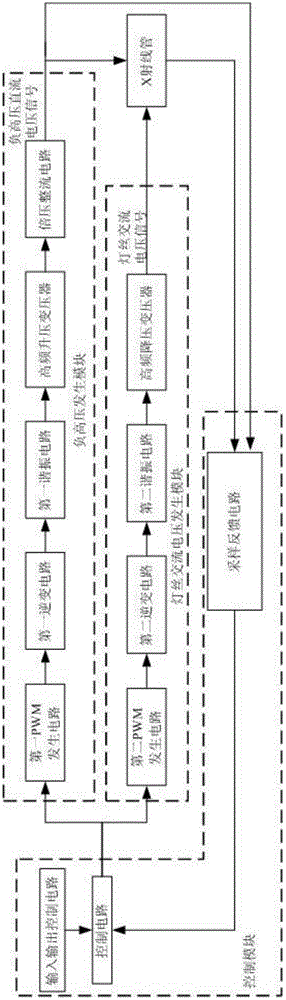

[0072] The negative high-voltage DC integrated power supply for X-ray tubes in this embodiment leads to 4 wires, such as figure 2 As shown, terminal 5 of the negative high-voltage DC integrated power supply leads to two high-voltage wires connected to terminal 3 of the X-ray tube and cathode terminal 4 of the X-ray tube, and terminal 6 of the negative high-voltage DC integrated power supply leads to a high-voltage wire to connect to the terminal of the X-ray tube 2. Terminal 7 of the negative high-voltage DC integrated power supply leads a wire to ground. The terminal 2 of the X-ray tube and the terminal 3 of the X-ray tube have an AC potential difference of 0-5 volts as the filament power supply, and the anode terminal 1 of the X-ray tube is grounded. When the X-ray tube is working, the electron flow generated by the filament hits the tungsten tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com