Grinding device for scale-like metal powder

A metal powder, flake-like technology, applied in the field of metal powder rolling devices, can solve the problems of less impact points, lower proportion of flat powder, large impact force, etc., and achieves the effects of fast processing, stable quality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

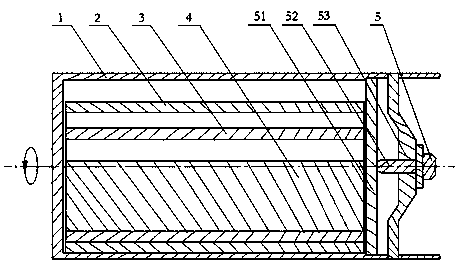

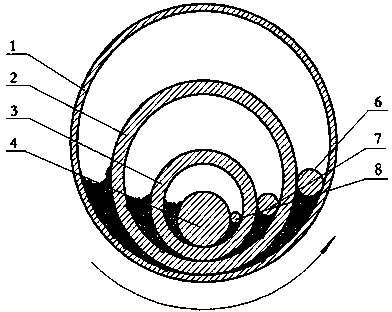

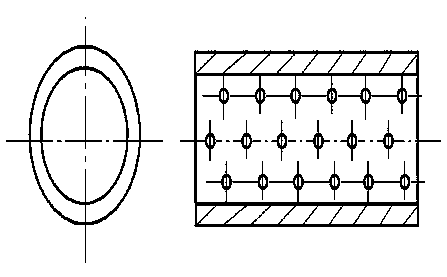

Embodiment 1

[0030] Ethanol is used as the dispersion medium, the volume ratio of the dispersion medium to the alloy powder is 6:1, and the amount of anti-rust and lubricant is 0.2% by mass of the metal powder. The inner diameter of the active roller 1 of the patented device of the present invention is Ф200mm; The internal length of the drum 1 is 1 mm to 5 mm shorter. The ratio of the mass of the primary roller 2, the secondary roller 3, the roller 4, the first roller 6, the second roller 7, and the third roller 8 to the mass of the alloy powder is 15:1. The linear velocity of the inner wall of the driving drum 1 is 300 m / min. After 60 hours of continuous operation, samples were taken. The samples have an average thickness of 0.70 μm and an aspect ratio of about 650. Measured with a laser particle size tester, the average particle diameter D50 is 65 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com