New high temperature resistant low viscosity high shear water-in-oil drilling fluid

A technology of high temperature resistance and drilling fluid, applied in the field of drilling fluid, can solve the problems of inability to ensure the safety of deep wells, rapid drilling, debris can not be removed in time, poor wellbore stability, etc., to enhance thermal stability and electrical stability, The effect of shortening drilling cycle and preventing wellbore collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

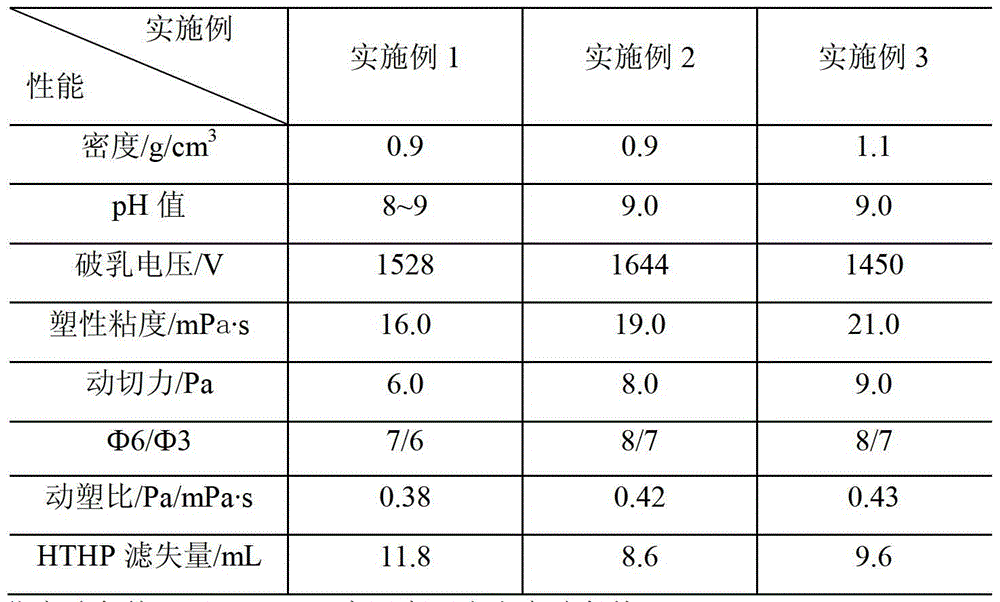

Embodiment 1

[0012] Weigh 360 mL of diesel oil, 40 mL of calcium chloride brine with a mass fraction of 20%, 24 g of DQGC, 8 g of DQNS, 12 g of BS-1C, 6 g of lime, and 16 g of DQHA; add diesel oil, main, auxiliary emulsifier, and organic bentonite into the high stirring cup in turn. , lime, fluid loss reducer and calcium chloride brine, each adding a treatment agent is stirred at a speed of 12000r / min, so that the treatment agent is fully dispersed in the system, and stirred for a total of 90min to prepare the drilling fluid of the present invention.

Embodiment 2

[0014] Weigh 360 mL of diesel oil, 40 mL of calcium chloride brine with a mass fraction of 20%, 26 g of DQGC, 9.2 g of DQNS, 16 g of BS-1C, 12 g of lime, and 24 g of DQHA; add diesel oil, main, auxiliary emulsifier, organic Bentonite, lime, fluid loss control agent and calcium chloride brine are stirred at a speed of 12000 r / min each time a treatment agent is added, so that the treatment agent is fully dispersed in the system, and stirred for a total of 90 minutes to prepare the drilling fluid of the present invention.

Embodiment 3

[0016] Weigh 360 mL of oil, 40 mL of calcium chloride brine with a mass fraction of 20%, 28 g DQGC, 14 g DQNS, 16 g BS-1C, 12 g lime, and 24 g DQHA; add diesel oil, main, auxiliary emulsifier, and organic bentonite into the high stirring cup in turn. , lime, fluid loss reducer and calcium chloride brine, each adding a treatment agent is stirred at a speed of 12000r / min, so that the treatment agent is fully dispersed in the system, and stirred for a total of 90min to prepare the drilling fluid of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com