Vacuum cavity chamber capable of rapidly changing gas-homogenizing mode

A vacuum chamber and fast technology, applied in the field of vacuum chambers, can solve the problems of large impact on equipment, influence on substrate deposition, and high cost of transformation, and achieve the effects of improving reliability, improving uniformity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The invention relates to a vacuum chamber capable of quickly replacing a uniform gas mode, which can be used for low-pressure gas phase processing technology experiments and detection of internal pressure parameters of the chamber. The air inlet and uniform air mode of this chamber can be changed quickly.

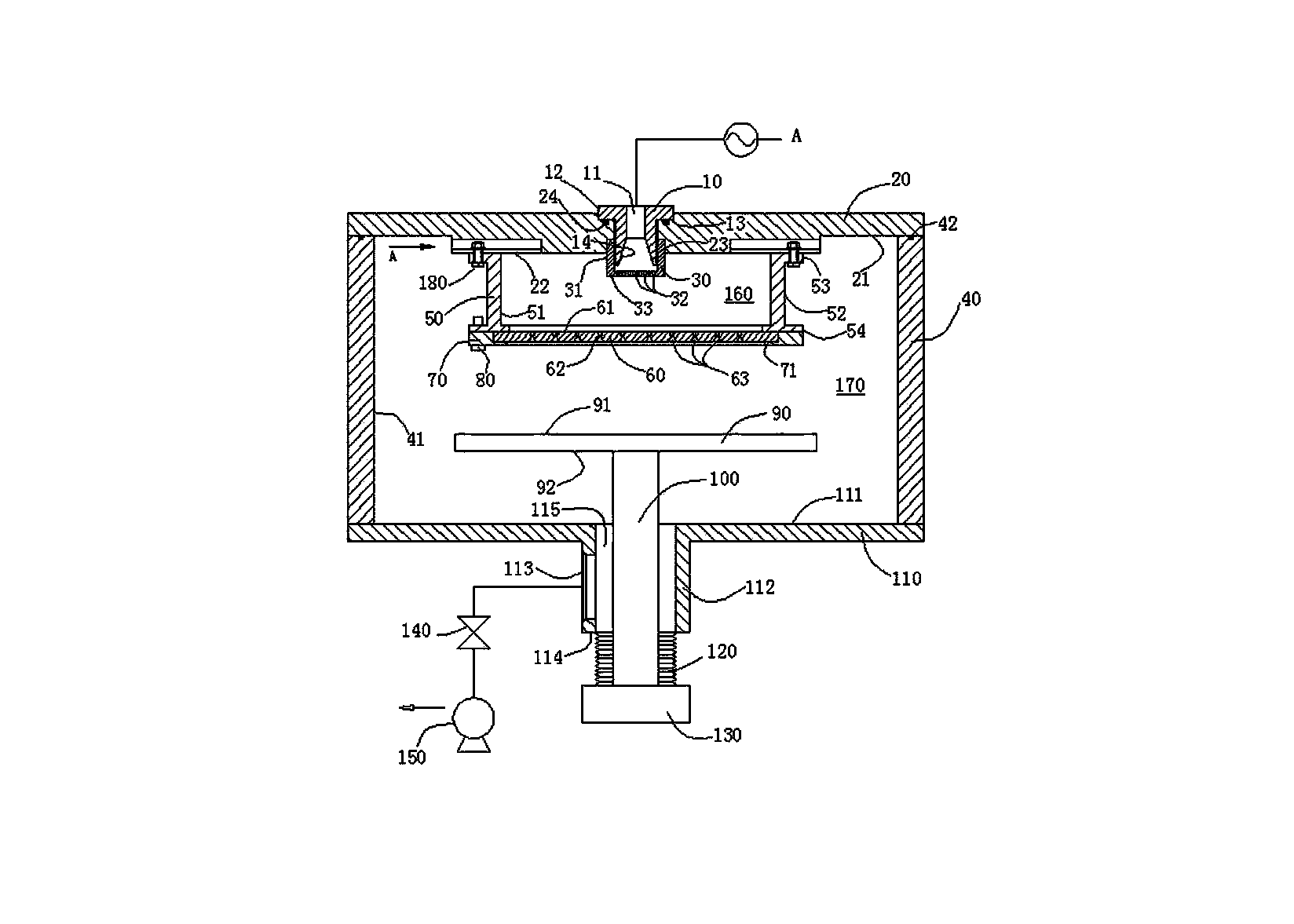

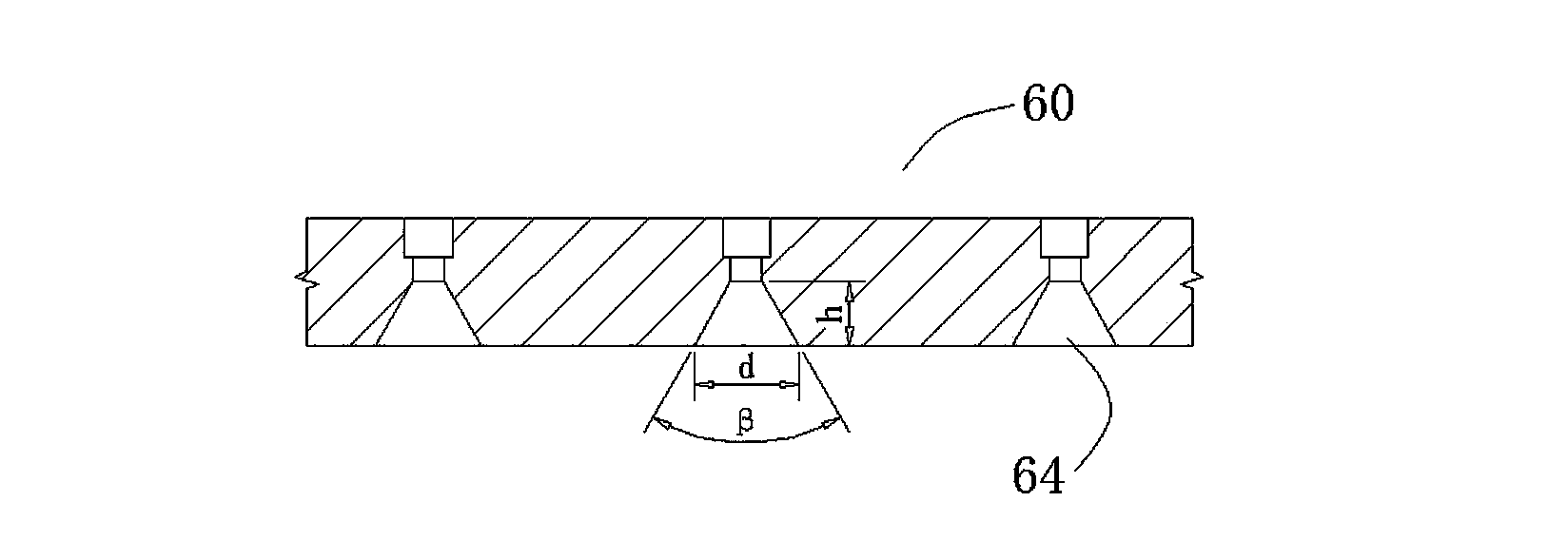

[0053] The vacuum chamber is a variable structure chamber, which consists of an air inlet nozzle 10, an upper cover 20, a first air distribution plate 30, a cavity, an inner lining 50, a second air distribution plate 60, a support plate 70, and a base 90 , The lifting device 100, the bellows 120, the throttle valve 140, the gas distribution system and the vacuum system.

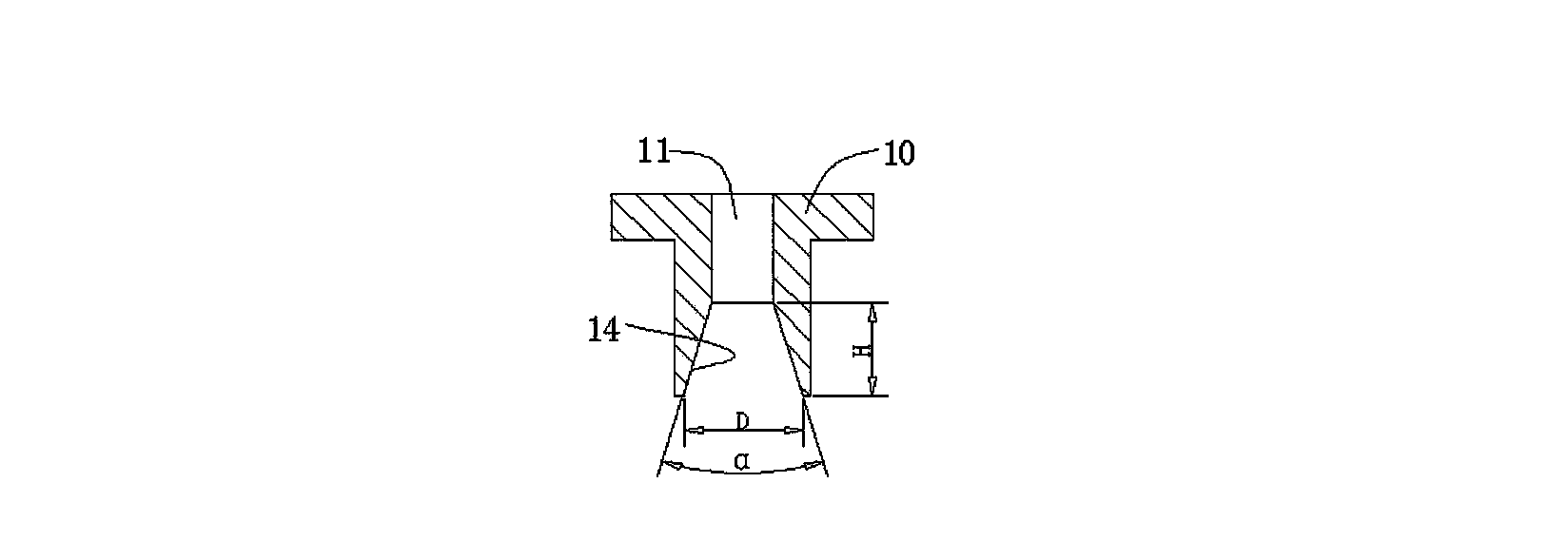

[0054] Such as figure 1 As shown, the present invention relates to a vacuum chamber that can quickly replace the uniform air mode, which is a vacuum chamber including a cavity 40, an upper cover 20 and a lower cover 110, and an air inlet nozzle is provided on the upper cover 20 10. An air distribution s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com