Electric transmission line tower made of composite materials

A technology of composite materials and transmission lines, applied in towers, building types, buildings, etc., can solve problems such as difficulties in construction, transportation, operation and maintenance, large head size of transmission towers, cumbersome processing and molding, etc., to reduce the size and weight of electrical layout Lightweight and easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

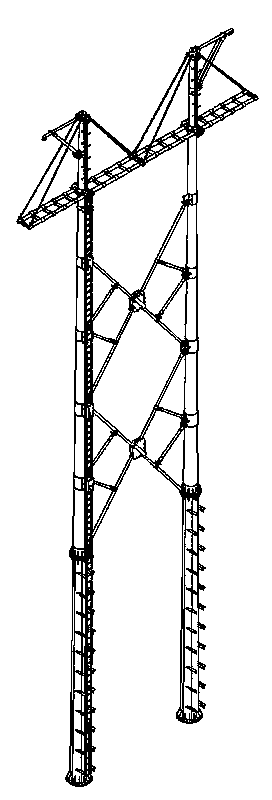

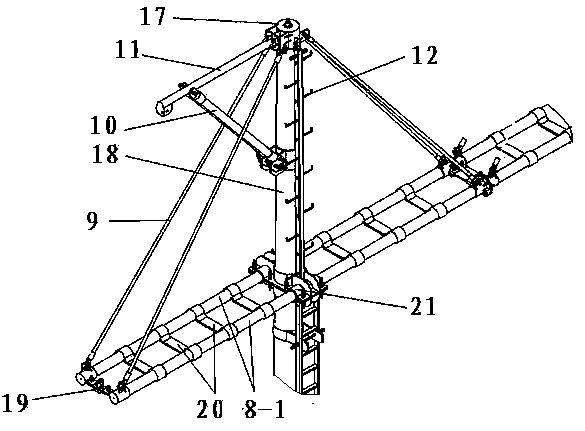

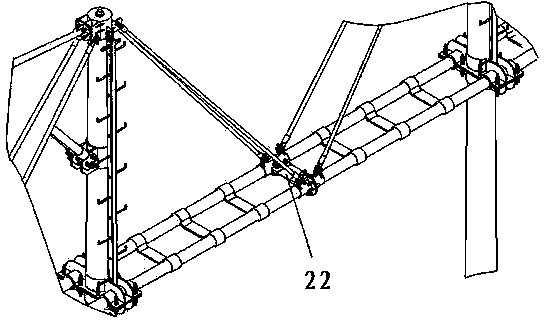

[0018] See Figure 1-4 , the tower head 18 and the upper body section 4 of the left and right components adopt composite materials, and the lower section 1 of the tower body is a steel pipe rod; The upper end flange 16-2 is connected; the lower part of the tower body 1 is connected to the steel ladder 2; the upper part of the tower body 4 of the composite material is connected to the composite material ladder 5, and the metal ladder 2 and the composite material ladder 5 are connected up and down and assembled at the joint Double ladder clamping plate 3; The tower head 18 of composite material connects composite material climbing ladder single ladder 12, and composite material climbing ladder single ladder 12 lower end connects the composite material climbing ladder 5 of tower body section; See figure 1 , 6 , two sets of support rods 6 are cross-connected between the tower body sections 4 of the left and right components, and the two clamping hoops 13 are connected by bolt...

Embodiment 2

[0021] See figure 1 , 4 , The tower head 18, the tower body section 4, the tower body lower section 1 and the ladder 2 connected to the tower body lower section 1 are all made of composite materials; other structures are the same as in Example 1. The lightning conductor is grounded from the outside of the shaft, which is convenient for normal and safe inspection of the lightning conductor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com