High-resolution micrometer vernier scale for micro electro mechanical system

A high-resolution vernier technology, applied in the field of high-resolution micro-electromechanical micro-vernier structure, can solve the problem of limited resolution and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

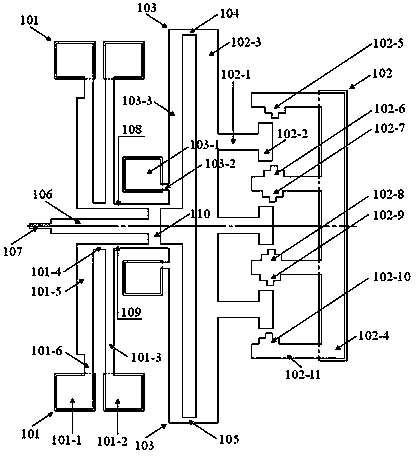

[0026] Attached below Figure 1~3 The present invention will be further described.

[0027] attached by figure 1 It can be seen that the high-resolution micro-electromechanical micrometer vernier of the present invention is composed of a one-dimensional mobile measuring vernier, a lever mechanism for amplifying the amount of movement, and a relative electrothermal actuator. beam.

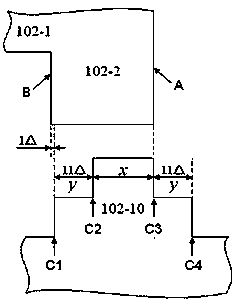

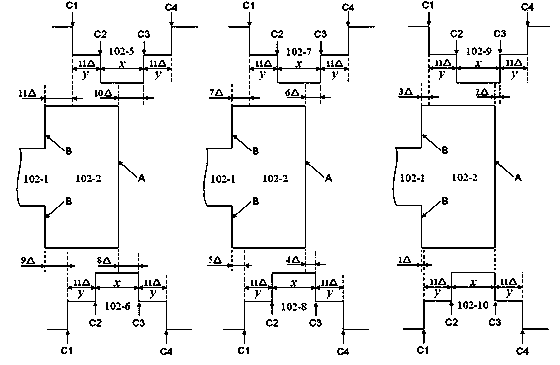

[0028] The one-dimensional mobile measuring vernier 102 is composed of left and right parts, wherein:

[0029] The left half of the one-dimensional mobile measuring vernier 102 includes a plurality of "T"-shaped structures with the same size and rotated 90 degrees clockwise. The "|" part (bottom) of the "T"-shaped structure is a horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com