Composite wave plate method based sum frequency laser

A compound wave plate and laser technology, applied in the field of compound wave plate method and frequency laser, can solve the problems of energy waste, affecting sum frequency efficiency, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings and examples.

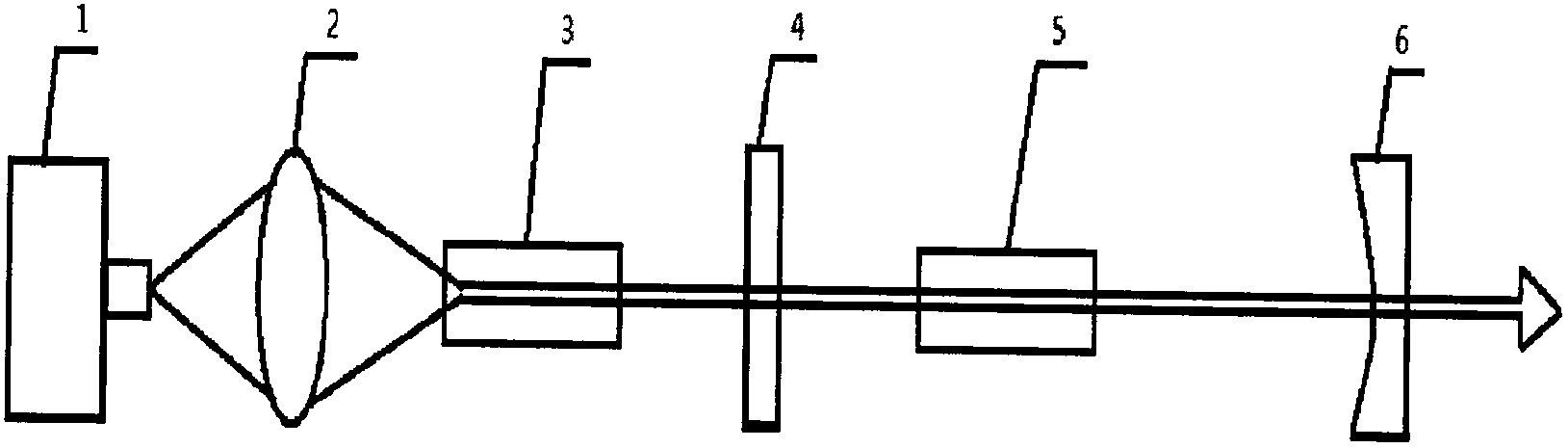

[0016] figure 1 It is the optical path diagram of the composite wave plate method sum frequency laser of the present invention.

[0017] Such as figure 1 As shown, the composite wave plate method and frequency laser of the present invention includes: a semiconductor laser, a coupling lens, a laser gain medium and an output mirror. In the optical path, the semiconductor laser 1 sends pump light, and enters the laser gain medium through the coupling lens 2 3, and the laser gain medium is pumped; the laser gain medium has polarization emissivity, forming spontaneous radiation, and the left end surface of the laser gain medium 3 and the output mirror 6 are respectively coated with a double-line total reflection film, and the laser gain medium Form the resonant cavity of the laser between the output mirror; In the above-mentioned resonant cavity, a composite wave plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com