Fixing method of 600MW steam-turbine generator stator coil end

A technology for turbo generators and stator windings, which is applied in the manufacture of motor generators, windings, electric components, etc. It can solve the problems of easily damaged end winding insulation, short-circuit motors, and difficult fixation, and achieve excellent mechanical properties and slow down heat. Stress, the effect of ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

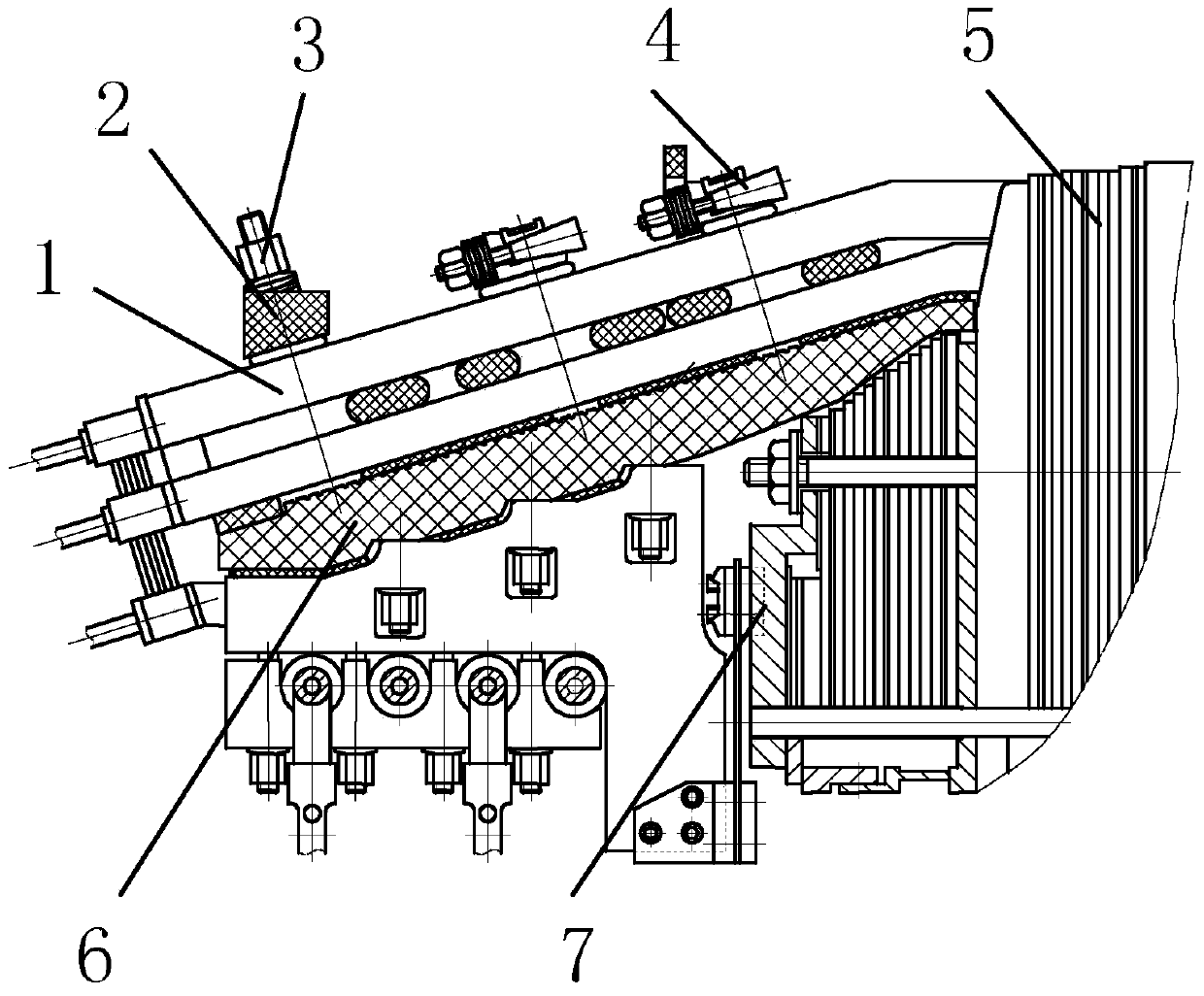

[0019] Such as figure 1 As shown, the present invention is a method for fixing the end of the stator winding of a 600MW turbogenerator: the outer side of the stator end winding 1 adopts a large-sized integral glass fiber reinforced plastic cone ring 6 as a supporting part for carrying the stator end winding 1 of a 600MW turbogenerator, When the unit is running or in an accident, it can give a supporting force to the end winding, and the large-size integral FRP cone ring 6 is fixed on the stator core 5 by a non-magnetic spring plate 7, which ensures the firmness of the FRP cone ring itself. The inner side of the stator end winding 1 adopts a fixed structure composed of two adjustable binding rings 4 close to the stator core 5 and a nose radial tension ring 2 away from the stator core 5. When the generator is running or suddenly fails, due to temperature When the change causes the axial expansion and contraction of the wire rod, the end of the stator winding can expand and contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com