Micro plastic forming device and forming method of laser-driven flying plate heat insulating film

A flying sheet heat insulation film and laser-driven technology, which is applied in the direction of microstructure devices, laser welding equipment, microstructure technology, etc., can solve the problems of low melting point of rubber, unsuitable for microplastic forming, etc., to reduce uneven deformation, Effect of reducing oxidation effect and improving formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

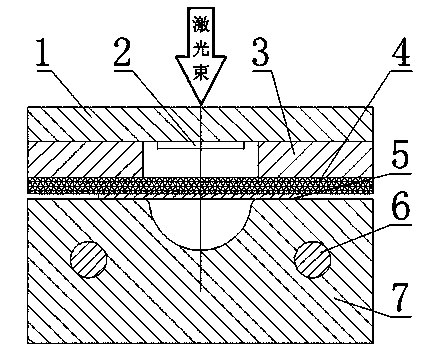

[0024] The structure of a laser-driven flyer thermal insulation film microplastic forming device of the present invention is as follows: figure 1 As shown, it includes the constrained layer 1, the flying sheet 2 attached to the lower surface of the constrained layer 1, the mold 7 containing the heating unit 6, the foil plate 5 placed on the upper surface of the mold 7, and the flying sheet between the constrained layer 1 and the foil plate 5. A heat-insulating soft film 4 is also arranged between the cavity 3 , the foil plate 5 and the flight cavity 3 . The soft membrane 4 is arranged close to the lower surface of the flight cavity 3 . The heating unit 6 is a heating tube in the shape of a cable duct, and the inside of the heating tube is a resistance wire. The flyer 2 is 0.017mm Al foil, and the foil plate 5 is 0.05mm Cu foil.

[0025] The invention relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com