Fixing device and method for electric vehicle charging port assembly socket with wiring harness

A fixed device, electric vehicle technology, applied in electric vehicles, electric traction, vehicle energy storage and other directions, can solve problems such as difficulty in meeting body appearance protection requirements, inability to meet mass production requirements, and inability to meet large wire welding requirements, etc. The market has broad practical prospects, is easy to promote, and meets the effect of large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the solution of the present invention more clearly, but the protection scope of the present invention is not limited thereby.

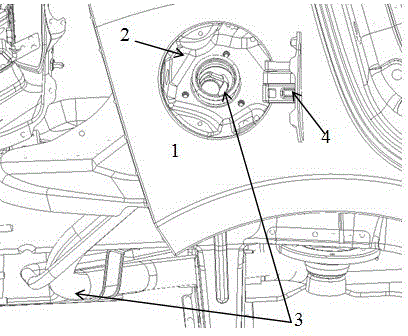

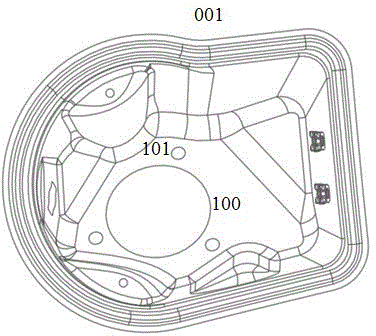

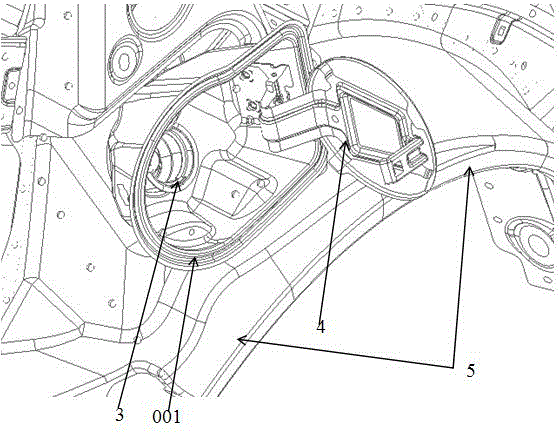

[0042] As described in the background technology, the main technical problem to be solved by the present invention is to utilize the attached figure 2 Fuel filler box 001 shown to secure the attached Figure 8 The charging port assembly socket 004 with a wiring harness shown in the figure is to realize the cooperating and fixing method of the charging port assembly socket and the body of the electric vehicle without changing the part of the body structure of the traditional gasoline vehicle on the same platform, and integrate this Fixed position selection on fuel filler. Just as described in the background technology, the fuel filler box 001 installed in the fuel fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com