Liquid fluorescent whitening agent and preparation method thereof

A fluorescent whitening agent and liquid technology, applied in chemical instruments and methods, luminescent materials, organic dyes, etc., can solve the problems of complex preparation methods, pollute the environment, and insignificant whitening effect, and reduce production costs and pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

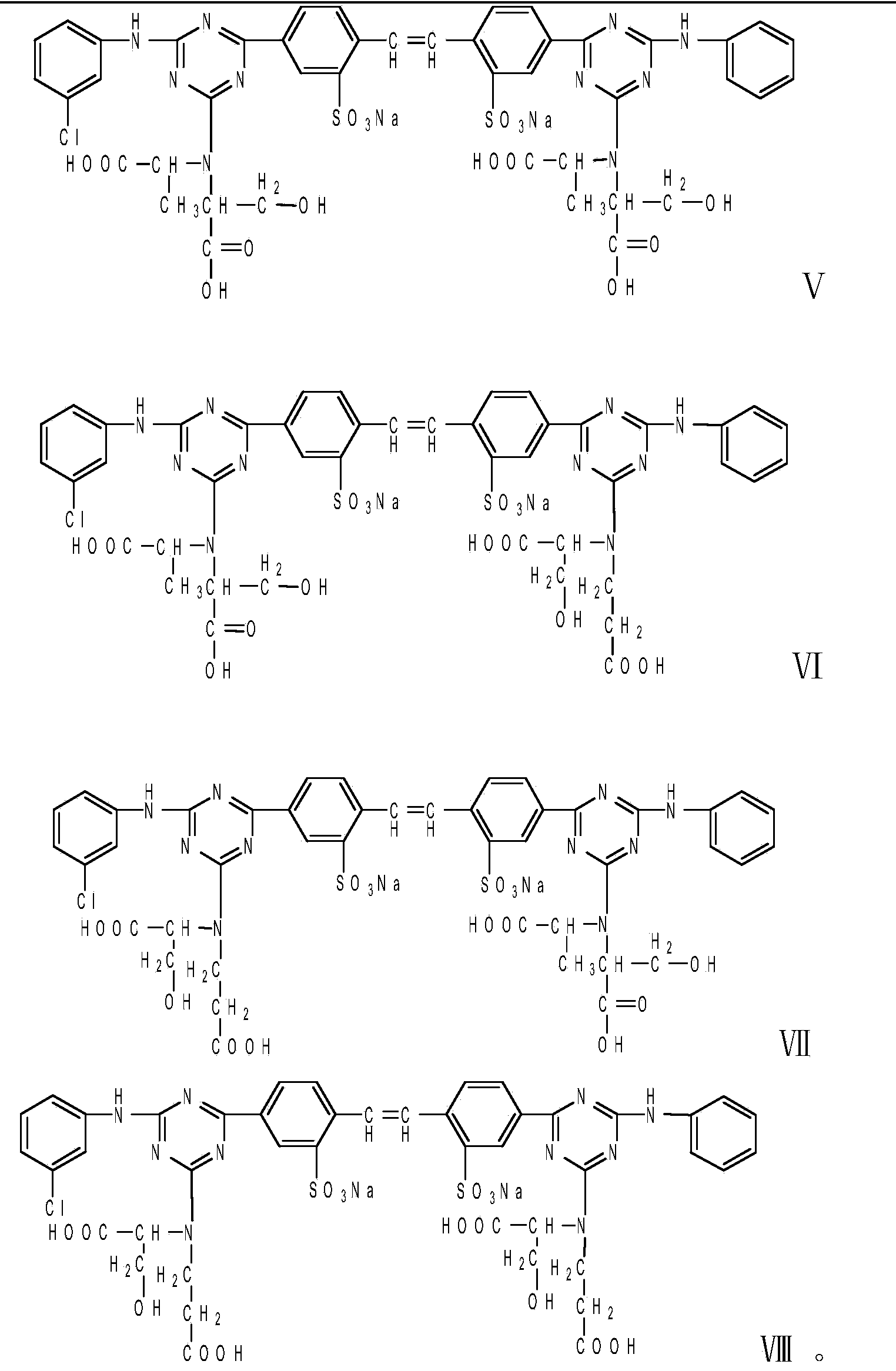

[0032] The liquid fluorescent whitening agent in this embodiment is mainly composed of V: 4,4'-bis[(4-m-chloroanilino-4'-anilino-6,6'-bis(2-acrylic acid serine amino )-1,3,5-triazin-2-yl)amino]stilbene-2,2'-disulfonic acid disodium salt, VI: 4,4'-bis[(4-m-chloroanilino- 4'-anilino-6-(1-acrylserine amino)-6'-(2-acrylserine amino)-1,3,5-triazin-2-yl)amino]stilbene-2, 2'-Disulfonic acid disodium salt, VII: 4,4'-bis[(4-m-chloroanilino-4'-anilino-6-(2-acrylserine amino)-6'-(1- Acrylserine amino)-1,3,5-triazin-2-yl)amino]stilbene-2,2'-disulphonic acid disodium salt and VIII: 4,4'-bis[(4-m Chloroanilino-4'-anilino-6,6'-bis(1-acrylserine amino)-1,3,5-triazin-2-yl)amino]stilbene-2,2'-di Disodium sulfonic acid consists of four components, and the structural formula of each component is:

[0033]

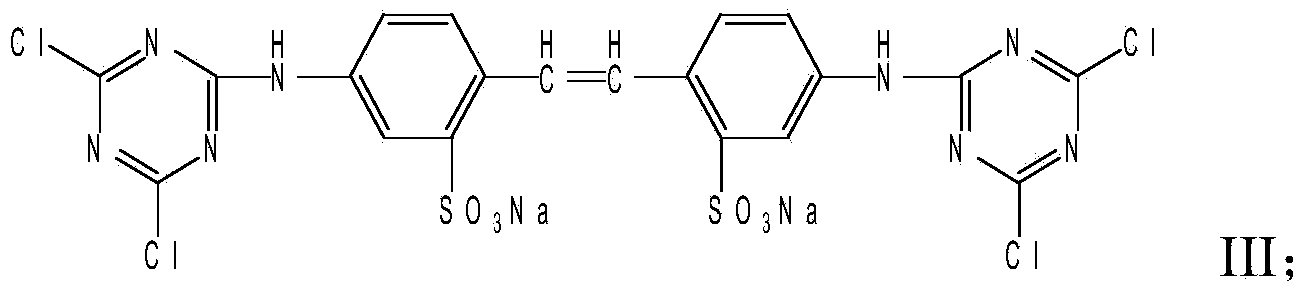

[0034] Above-mentioned liquid optical brightener, its preparation method is:

[0035] 1) Weigh 30g of cyanuric chloride, 27.2g of 4,4'-diaminostilbene-2,2'-disulfonic acid, 6.8g of an...

Embodiment 2

[0047] The liquid fluorescent whitening agent in this embodiment is the same as the liquid fluorescent whitening agent in Example 1.

[0048] Above-mentioned liquid optical brightener, its preparation method is:

[0049] 1) Weigh 30g of cyanuric chloride, 33.2g of 4,4'-diaminostilbene-2,2'-disulfonic acid, 8.3g of aniline, 11.4g of m-chloroaniline, 11.7g of acrylic acid and 18g of serine;

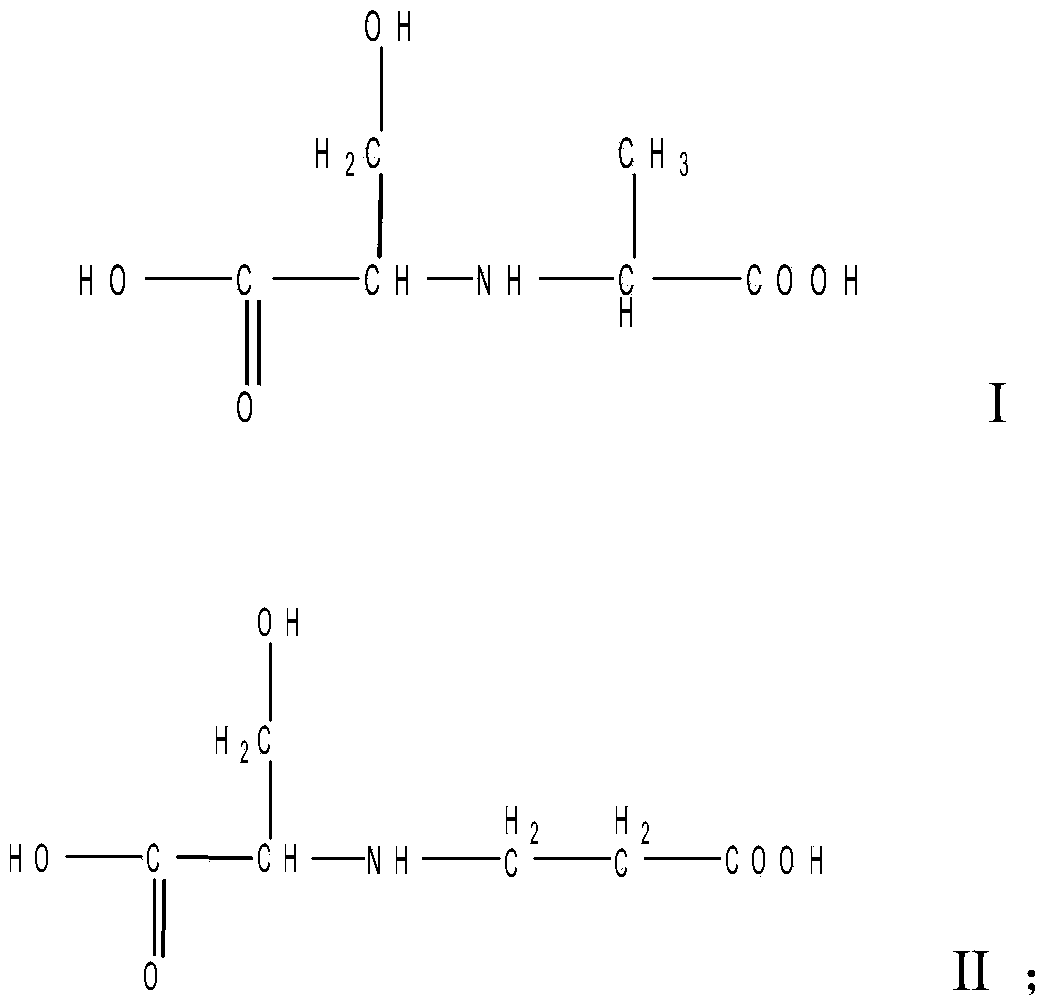

[0050] 2) Add 30g of pure water into the reaction vessel, add 11.7g of acrylic acid and 18g of serine into the reaction vessel to dissolve in turn, and react at 90°C for 3.5h to obtain a mixture of triple-condensed intermediates I and II, whose structural formula is:

[0051]

[0052] 3) Add 180g of 30% NaOH solution into the reaction container, add 33.2g of 4,4'-diaminostilbene-2,2'-disulfonic acid (100%) into the container solution, stir evenly to obtain 4 , an aqueous solution of 4'-diaminostilbene-2,2'-sodium disulfonate;

[0053] 4) Add 600g of 0°C ice water into the reaction vess...

Embodiment 3

[0061] The liquid fluorescent whitening agent in this embodiment is the same as the liquid fluorescent whitening agent in Example 1.

[0062] Above-mentioned liquid optical brightener, its preparation method is:

[0063] 1) Weigh 30g of cyanuric chloride, 30g of 4,4'-diaminostilbene-2,2'-disulfonic acid, 7.5g of aniline, 10.3g of m-chloroaniline, 11.7g of acrylic acid and 17g of serine;

[0064] 2) Add 30g of pure water into the reaction vessel, add 11.7g of acrylic acid and 17g of serine into the reaction vessel to dissolve in turn, and react at 90°C for 3 hours to obtain a mixture of triple-condensed intermediates I and II, whose structural formula is:

[0065]

[0066] 3) Add 180g of NaOH solution with a concentration of 30% into the reaction container, add 30g of 4,4'-diaminostilbene-2,2'-disulfonic acid (100%) into the container solution, and stir evenly to obtain 4, Aqueous solution of sodium 4'-diaminostilbene-2,2'-disulfonate;

[0067] 4) Add 600g of 0°C ice water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com