LED epitaxial wafer, manufacturing method thereof, and LED chip including same

A technology of LED epitaxial wafers and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of high driving voltage and low brightness, and achieve the effects of reducing light absorption, increasing light-emitting area, and improving brightness and light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

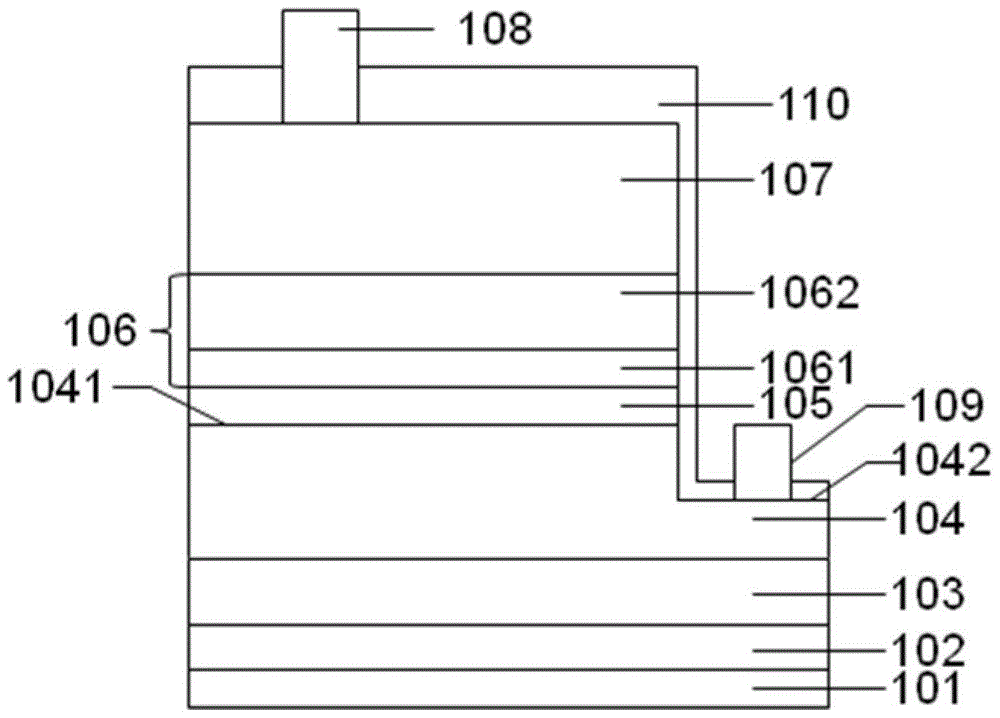

Embodiment 1

[0061] This embodiment provides a method for manufacturing an LED chip. The method includes forming an epitaxial layer on the surface of a substrate, forming a tunnel junction layer on the epitaxial layer, and manufacturing a P electrode, an N electrode, and a protective layer.

[0062] Step S1, forming an epitaxial layer on the surface of the substrate, comprising the following steps:

[0063] Raise the temperature from room temperature to 1100°C in 490 seconds, and process the sapphire substrate for 5 minutes under the conditions of hydrogen atmosphere and reaction chamber pressure of 180mbar;

[0064] Cool down to 560°C in 420 seconds, control the pressure of the reaction chamber at 480mbar, and grow a GaN buffer layer with a thickness of 40nm on the sapphire substrate;

[0065] After 350 seconds, the temperature was raised to 1100°C, the pressure of the reaction chamber was controlled at 480mbar, and the undoped GaN of 2.5μm was continuously grown, that is, the first U-typ...

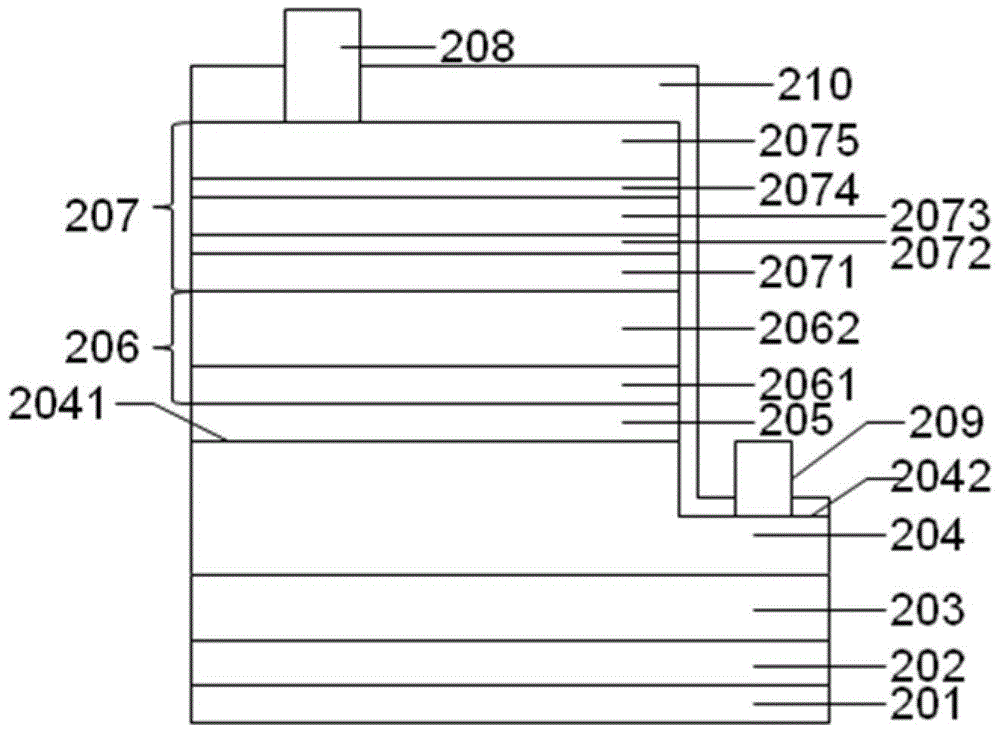

Embodiment 2

[0078] This embodiment provides a method for manufacturing an LED chip. The method includes forming an epitaxial layer on the surface of a substrate, forming a tunnel junction layer on the epitaxial layer, and manufacturing a P electrode, an N electrode, and a protective layer.

[0079] In this embodiment, the step of forming an epitaxial layer on the surface of the substrate is the same as the step S1 of the first embodiment, and the steps of forming the N electrode, the P electrode and the protective layer are the same as the step S3 of the first embodiment.

[0080] The step of forming a tunnel junction layer on the epitaxial layer is different from step S2 in embodiment 1. In this embodiment, step S2 is:

[0081] Keep the temperature at 1000°C, the pressure in the reaction chamber at 200mbar, control the flow rate of Mg to 2500sccm, and grow a heavily doped P-type GaN layer with a thickness of 20nm, that is, the second P-type GaN layer, in which the doping concentration of ...

Embodiment 3

[0085] This embodiment provides a method for manufacturing an LED chip. The method includes forming an epitaxial layer on the surface of a substrate, forming a tunnel junction layer on the epitaxial layer, and manufacturing a P electrode, an N electrode, and a protective layer.

[0086] In this embodiment, the step of forming an epitaxial layer on the surface of the substrate is the same as the step S1 of the first embodiment, and the steps of forming the N electrode, the P electrode and the protective layer are the same as the step S3 of the first embodiment.

[0087] The step of forming a tunnel junction layer on the epitaxial layer is different from step S2 in embodiment 1. In this embodiment, step S2 is:

[0088] Keep the temperature at 1100°C, the pressure in the reaction chamber at 600mbar, control the flow of Mg to 2600sccm, and grow a heavily doped P-type GaN layer with a thickness of 30nm, that is, the second P-type GaN layer, in which the doping concentration of Mg is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com