Method for coating quickly-solidified white LED fluorescent glue

A fast-curing, fluorescent adhesive technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high defect rate, inconsistent residence time, different degrees of fluorescent adhesive sedimentation, etc., to reduce the defect rate of bubbles, shorten the production cycle, The effect of shortening the curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

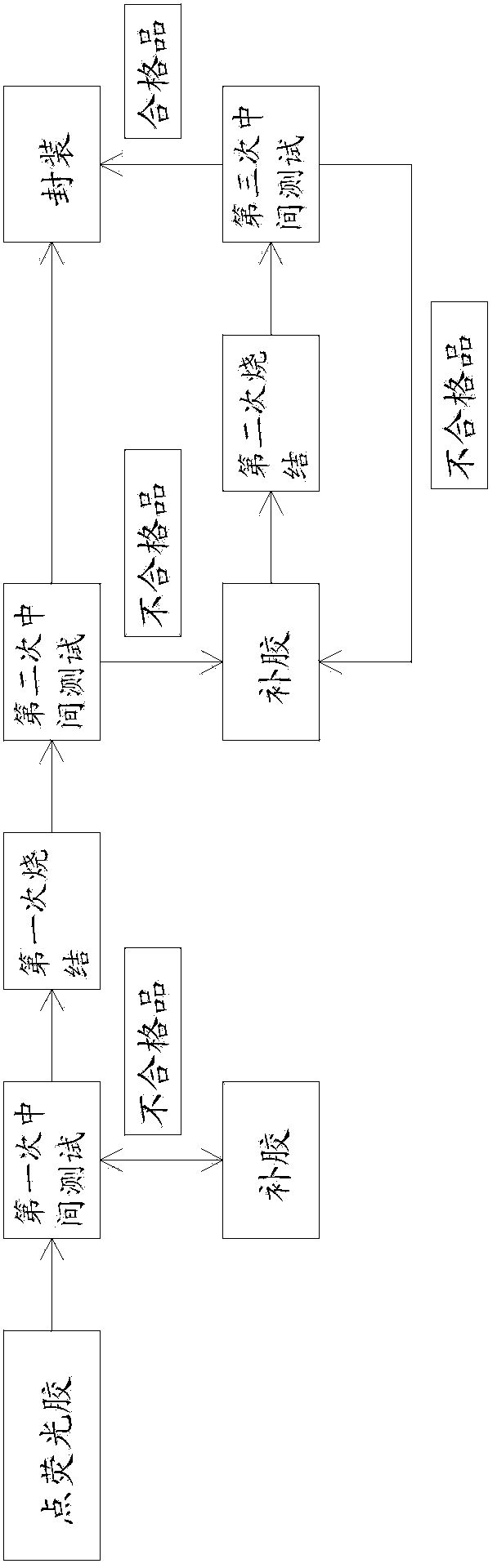

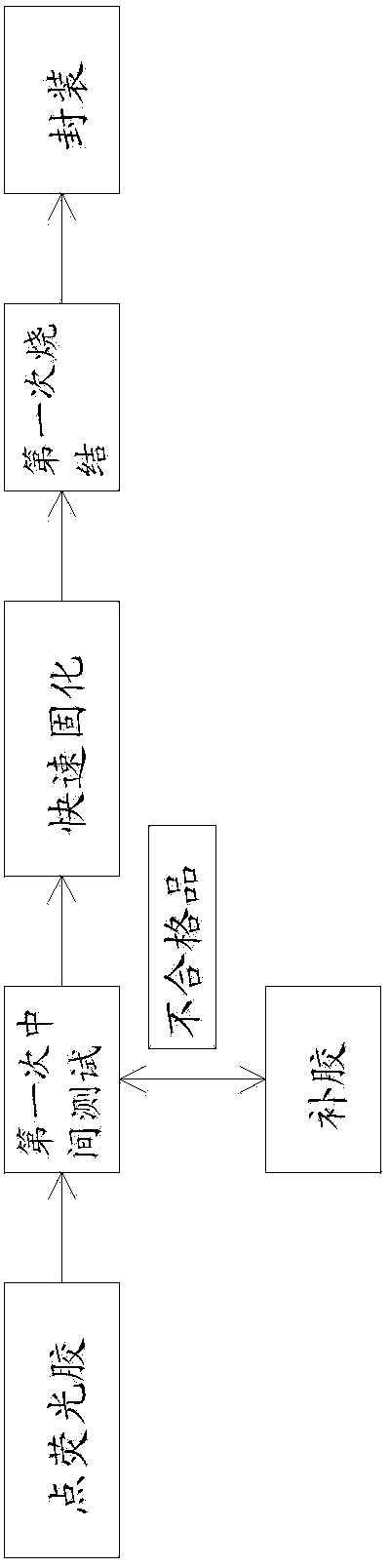

[0022] The idea of the present invention is that, in the original technological process (such as figure 1 ) on the basis of a new rapid curing process (such as figure 2 ), that is to remove the second intermediate test, glue filling, third intermediate test, second sintering and other processes, after the fluorescent glue is placed and the first intermediate test is performed, immediately use the heating block for the qualified products ( 150°C, 1-5min) for rapid curing. Using the rapid curing method, the fluorescent glue stays at the moment when it is more consistent after dispensing, so as to minimize the difference in the distribution of fluorescent glue caused by staying and curing. The impact of subsequent curing and encapsulation on the distribution of fluorescent glue is avoided. At the same time, the batch production process is consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com