Brake device and brake method for vibratory screen motor of asphalt mixing station

A technology of motor braking and vibrating screen, which is applied in the deceleration device of AC motor, electric motor/converter plug, etc., can solve the problems of shortening the service life of vibrating screen, prolonging the downtime of vibrating screen, and unstable shutdown process. Elimination of resonance phenomena, reduction of downtime, downtime reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

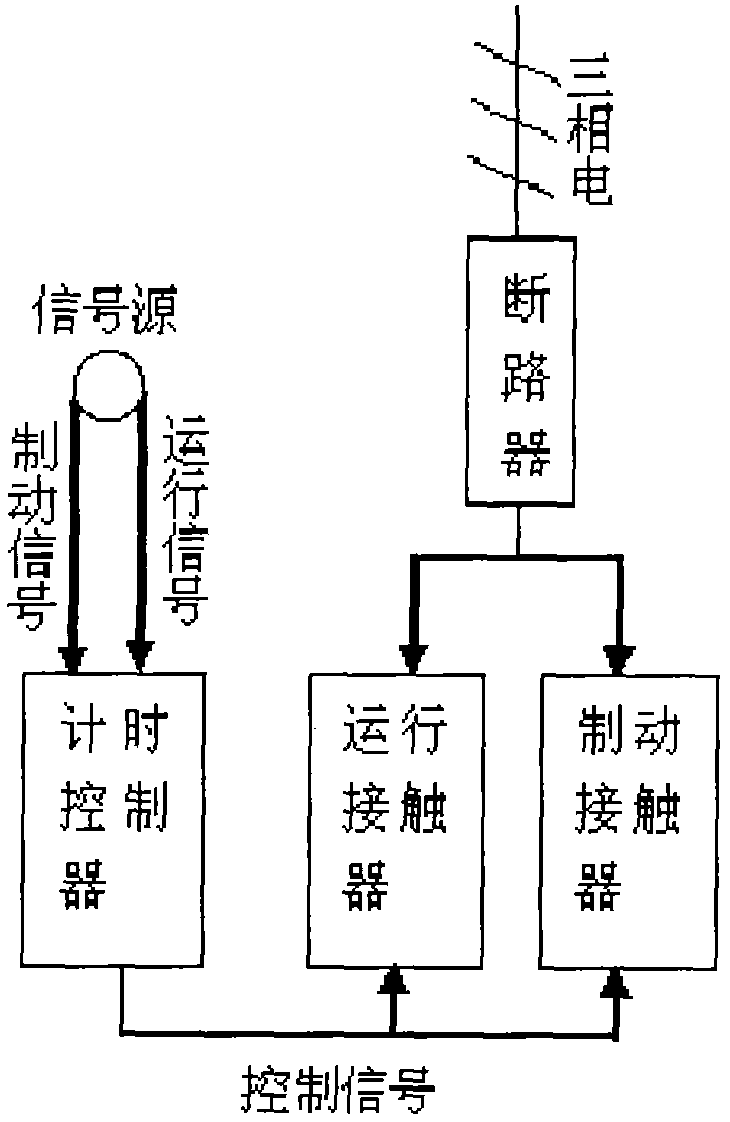

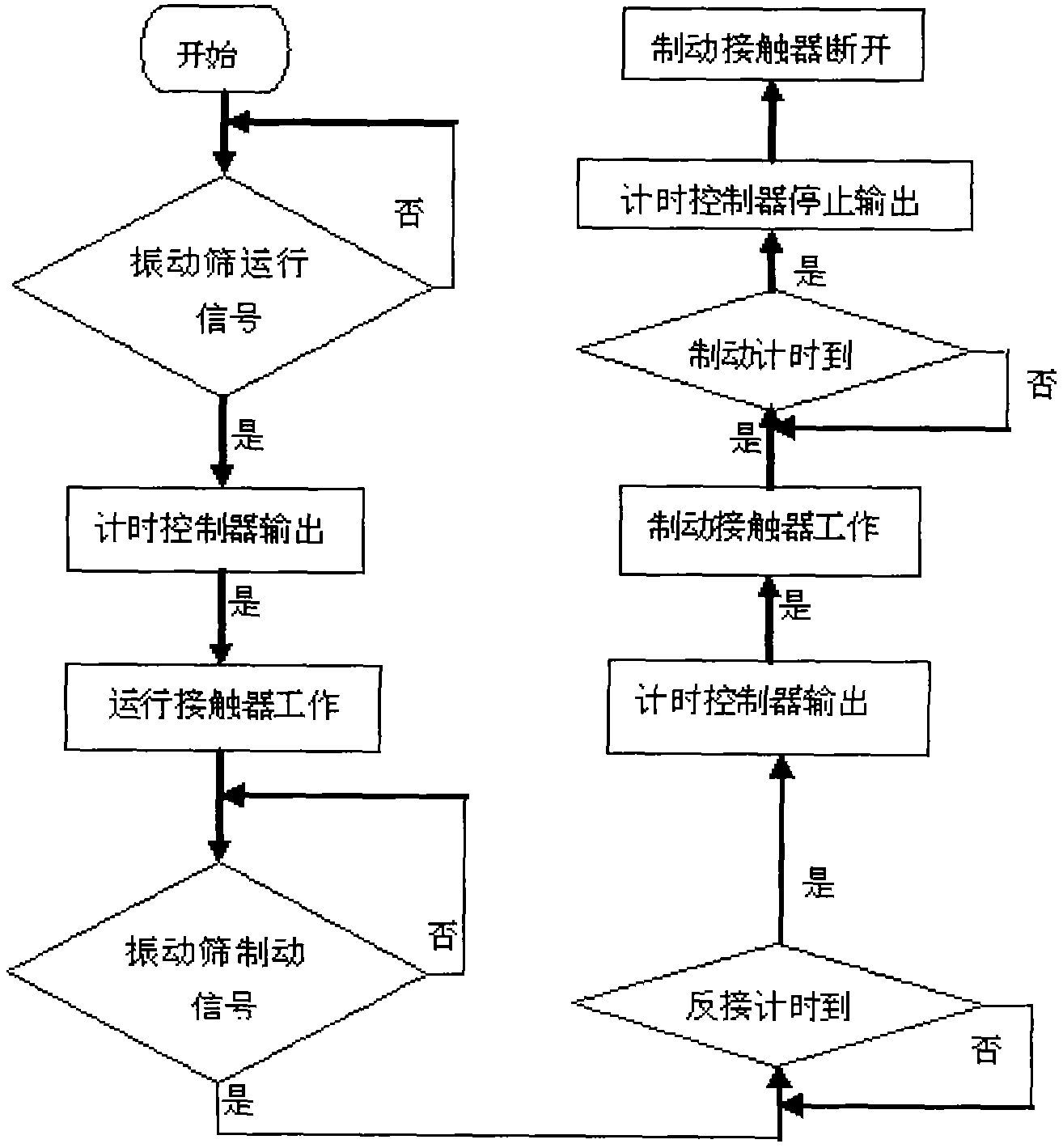

[0024] Such as figure 1 As shown, the braking device of the vibrating screen motor of the asphalt mixing plant based on time control includes a circuit breaker, a contactor, a signal source, and a timing controller; the signal source provides the running signal and braking signal of the vibrating screen motor; the contactor includes a running contactor and Braking contactor; the timing controller selects to turn on or off the running contactor or braking contactor after receiving the control signal from the signal source, and the circuit breaker is connected to the running contactor and braking contactor respectively. Starting, running and braking play a protective role. The running contactor and braking contactor provide normal running power and reverse braking power for the vibrating screen motor respectively.

[0025] The timing controller is the core of the whole device, and its main functions are reverse braking start timing, braking operation timing, and connecting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com