Catalytic cracking catalyst containing Y-type molecular sieve and preparation method thereof

A catalytic cracking and catalyst technology, applied in molecular sieve catalysts, catalytic cracking, physical/chemical process catalysts, etc., can solve the problems of high differential thermal destruction temperature, low silicon-aluminum ratio, and unsuitable catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

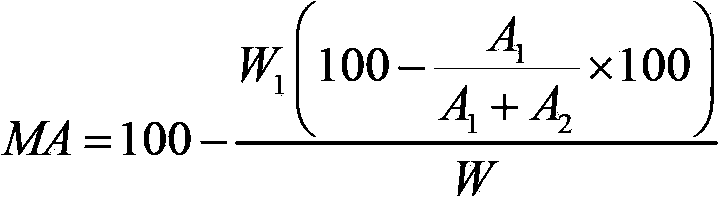

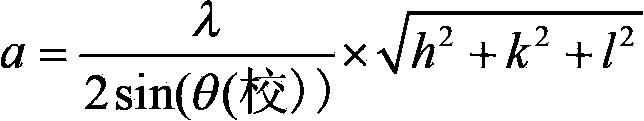

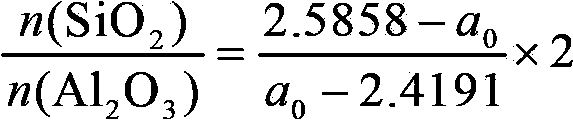

Image

Examples

Embodiment 1

[0062] Example 1: Preparation method of Y-type molecular sieve containing high stability small grains and catalytic cracking catalyst

[0063] (1) Preparation of the improved directing agent: Take 0.9g of polyethylene glycol 600 (Tianjin Ruijinte Chemical Co., Ltd., chemically pure) and add it to 18g of water to form solution A; take 6.6g of sodium hydroxide (Beijing Chemical Plant , analytically pure) was added to 20g of water, stirred until the sodium hydroxide was completely dissolved, and then 1.1g of pseudo-boehmite (Shandong Aluminum Company Research Institute, industrial product, Al 2 o 3 Content 72.0wt%), stirring until the pseudo-boehmite is completely dissolved to obtain sodium metaaluminate solution B. Solution B and 43.6g water glass (Beijing Red Star Soda Soda Factory, SiO 2 Content 27.81wt%, Na 2 O content 8.74wt%) was poured into solution A in turn, stirred evenly, and aged at 30°C for 24 hours to obtain an improved directing agent containing surfactant. Bas...

Embodiment 2

[0070] Each raw material source is with embodiment 1

[0071] (1) Preparation of improved directing agent: Take 5g of APE (Tianjin Ruijinte Chemical Co., Ltd., chemically pure) and add it to 20g of water to form solution A; take 3.5g of sodium hydroxide and add it to 13.3g of water, stir until the hydroxide After all the sodium is dissolved, 1.8 g of pseudo-boehmite is added, and stirred until the pseudo-boehmite is completely dissolved to obtain sodium metaaluminate solution B. Pour solution B and 54.8g of water glass into solution A in sequence, stir well and then age at 20°C for 24 hours to obtain an improved directing agent containing surfactant. Based on 100wt% of the directing agent, the content of APE is 5wt%, and the molar ratio of the other components is: 9.5Na 2 O: Al 2 o 3 :20SiO2 2 :300H 2 O.

[0072] (2) Preparation of NaY molecular sieve: Dissolve 15g of aluminum sulfate in 100g of water to form Al 2 o 3 Aluminum sulfate solution C with a content of 5.3 w...

Embodiment 3

[0078] Each raw material source is with embodiment 1

[0079] (1) Preparation of improved directing agent: Take 2g polyethylene glycol 2000 and 2g Tween-40 (Tianjin Ruijinte Chemical Co., Ltd., chemically pure) and add it to 30g water to form solution A; take 4g sodium hydroxide Add it into 13 g of water, stir until the sodium hydroxide is completely dissolved, then add 1.1 g of pseudo-boehmite, and stir until the pseudo-boehmite is completely dissolved to obtain sodium metaaluminate solution B. Pour solution B and 42g of water glass into solution A in sequence, stir well and then age at 40°C for 8 hours to obtain an improved directing agent containing surfactant. Based on 100wt% of the directing agent, the content of polyethylene glycol 2000 and Tween-40 is 4.2wt%, and the molar ratio of the other components is: 14Na 2 O: Al 2 o 3 :25SiO2 2 :500H 2 O.

[0080] (2) Preparation of NaY molecular sieve: Dissolve 5.4g of aluminum sulfate in 100g of water to form Al 2 o 3Al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com