Heat conduction block

A technology of heat conduction block and heat conduction column, which is applied in the direction of conductors, non-insulated conductors, heating or cooling equipment, etc., which can solve the problems of high production cost, high metal cost, burns of users, etc., and achieve less injury or discomfort, and skin temperature The effect of low change amount and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

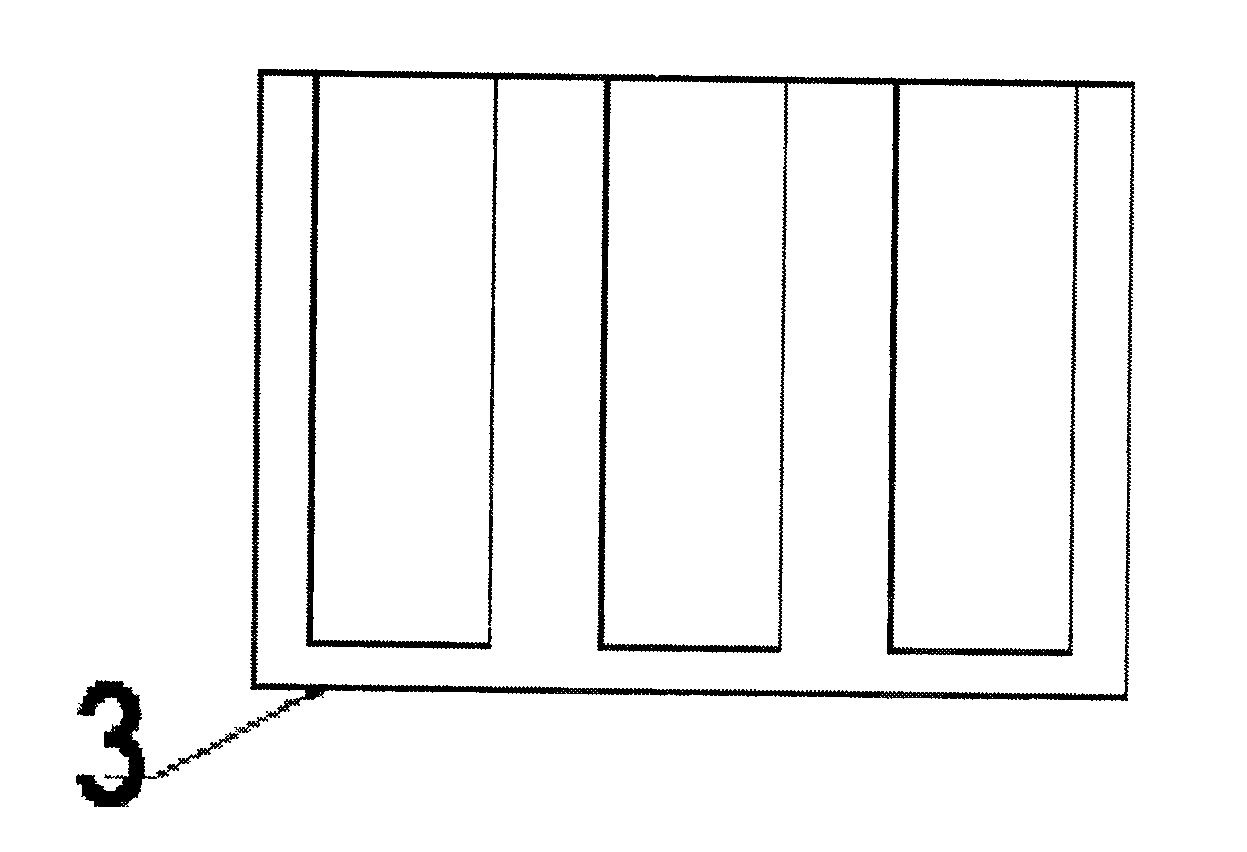

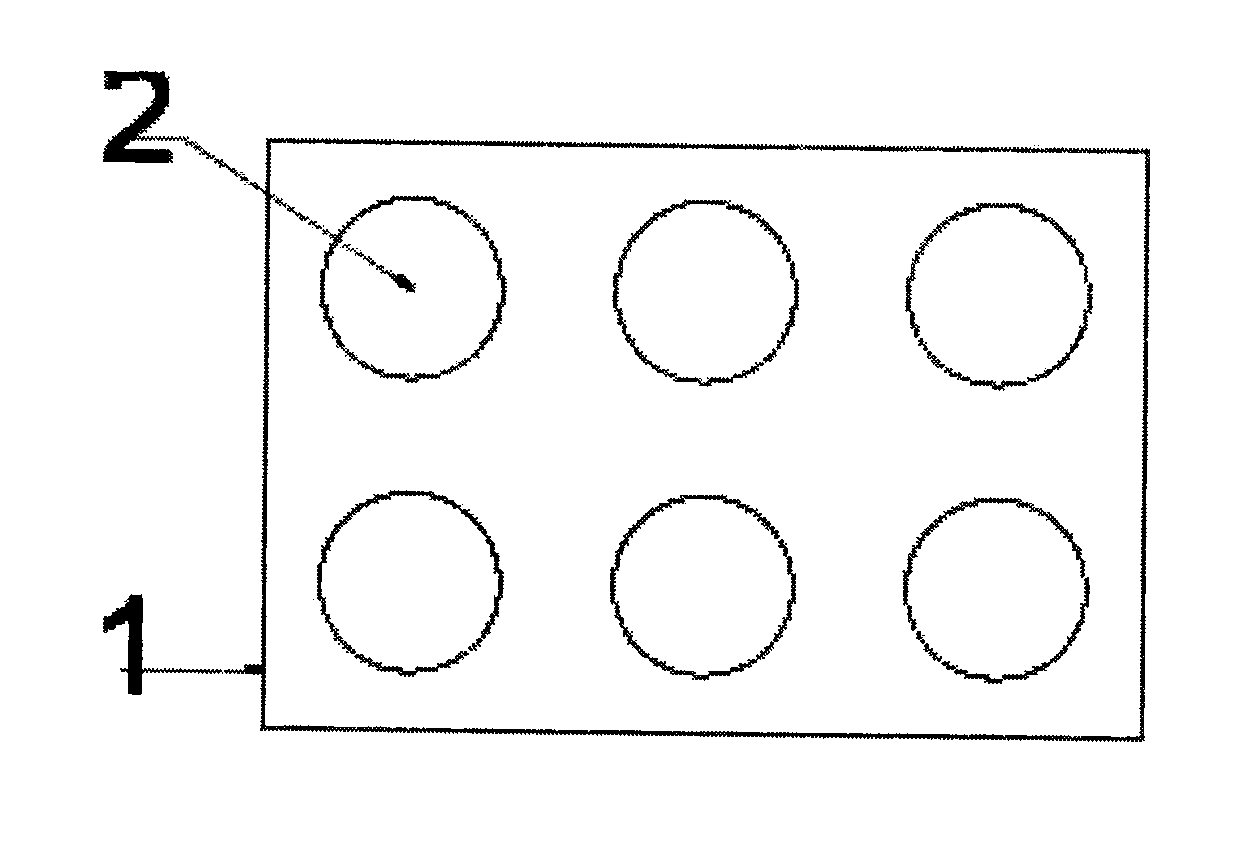

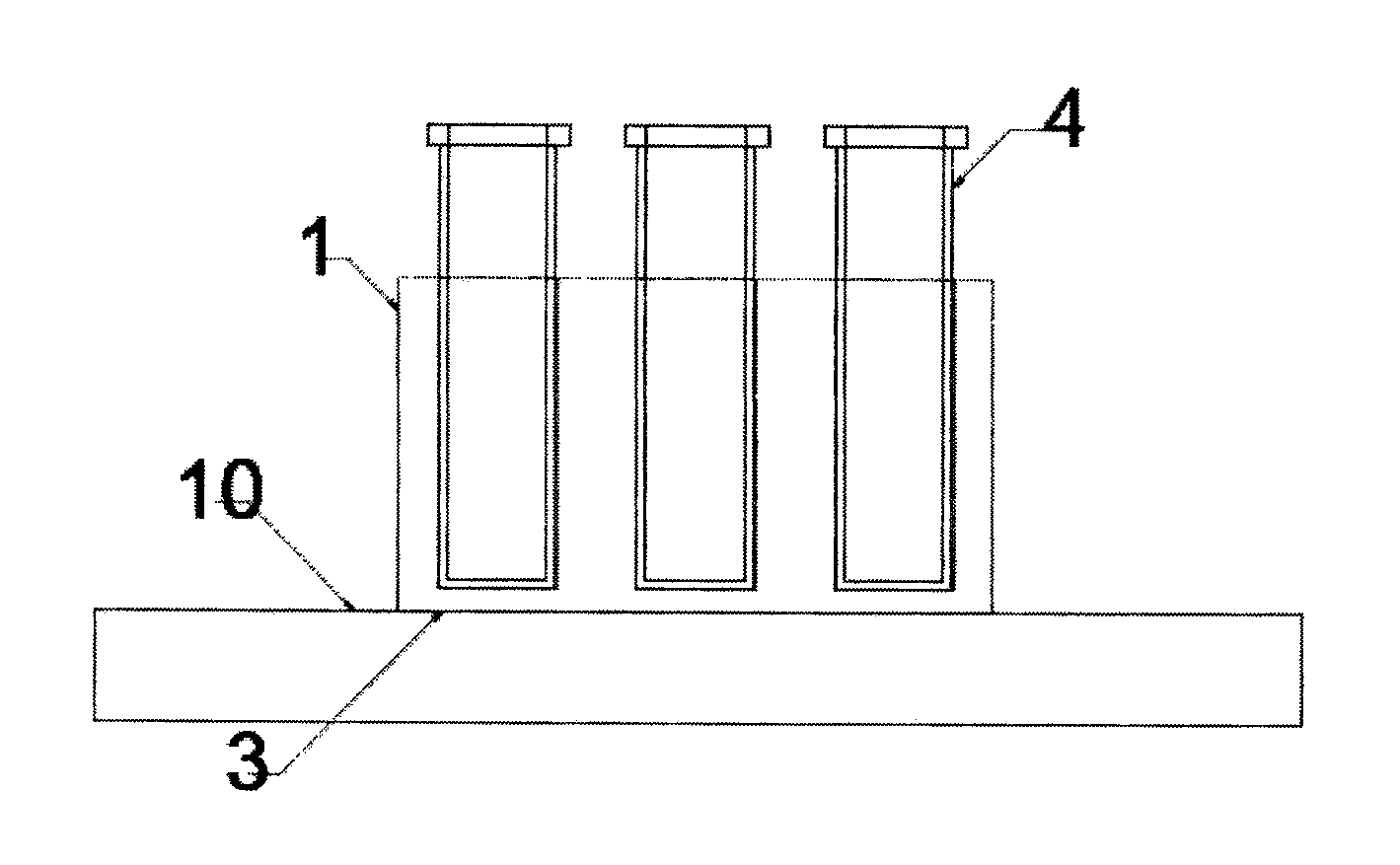

[0043] Embodiment 1: A heat conduction block 1, the heat conduction block 1 is composed of two parts, the first part is a heat conduction column 5, and the heat conduction column 5 is a cylindrical structure made of a material with high thermal conductivity, and the heat conduction column One end face of the cylinder is a plane, and the plane is connected to the heat source plane. The other end of the heat conduction cylinder has a conical or cylindrical hole 7, and the surface of the conical hole or cylindrical hole is connected to the outside of the test tube. In cooperation, the second component is a frame mechanism made of a material with low thermal conductivity, the frame structure has one or more through holes, and the heat conducting column can be placed in the through holes of the frame mechanism.

[0044] The frame of this embodiment is made of solid silicone rubber material, usually in a scale press vulcanization process. The heat conduction column is made of alumin...

Embodiment approach 2

[0048] Embodiment 2: The heat conduction column has a flange edge. The frame is made of silicone rubber material, usually made by large-scale pressure vulcanization process. The heat conduction column is made of aluminum alloy through turning. The diameter of the flange side of the heat conduction column is slightly larger than the diameter of the mounting hole of the frame under natural conditions. When the heat conduction column is installed, the inner wall of the frame mounting hole is subjected to the radial force of the flange edge of the heat conduction column, and its diameter is enlarged, so that the heat conduction column can penetrate the heat conduction hole. After the heat conduction column penetrates, the diameter of the installation hole returns to the natural state, and the flange of the heat conduction column plays the role of fixing the heat conduction column to the frame installation hole. Embodiment 2 has two kinds of heat conduction columns, the differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com