Wet process flue gas desulfurization water drop-shaped grout spraying pipe

A technology of wet flue gas desulfurization and spray pipe, which is applied in the field of slurry spray pipe and spray system, which can solve the problems of reduced desulfurization efficiency, enhanced flue gas distribution unevenness, and hindered uniform mixing of gas and liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

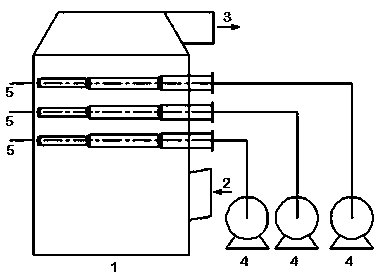

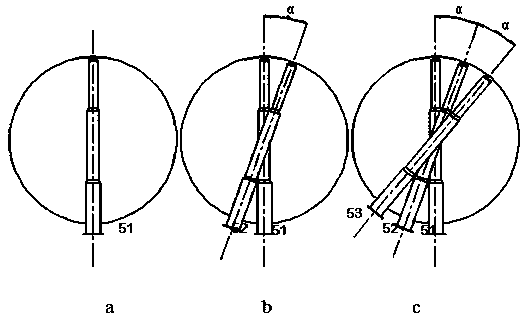

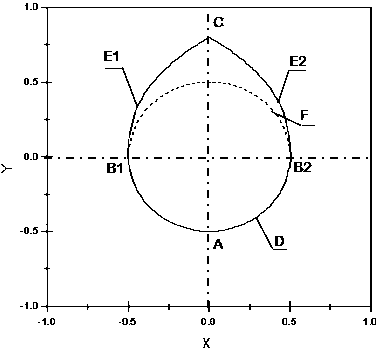

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings. Take the wet flue gas desulfurization system of a 300MW unit as an example. For layout of absorption tower and slurry supervisor, see figure 1 and figure 2 . Three layers of slurry spray layers are set in the absorption tower. The slurry main pipes of each spray layer are hollow shells composed of drop-shaped section lines, see image 3 . The slurry main pipe is straight and has the same diameter as the absorption tower. The slurry supervisors of each layer are arranged in a staggered order up and down, and the staggered angle is 20°. The vertical distance between adjacent spray layers is 2m. The branch pipe connected to the main slurry pipe adopts a round pipe, and the single-layer slurry pipe network is in the shape of a leaf vein, so that the limestone slurry can completely cover the horizontal section of the absorption tower.

[0026] In the x-y coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com