High-quality graphene dispersion method and film preparation method

A film preparation and graphene technology, applied in the field of graphene, can solve problems such as difficult to remove, impact, dispersant residue, etc., and achieve excellent electrical and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

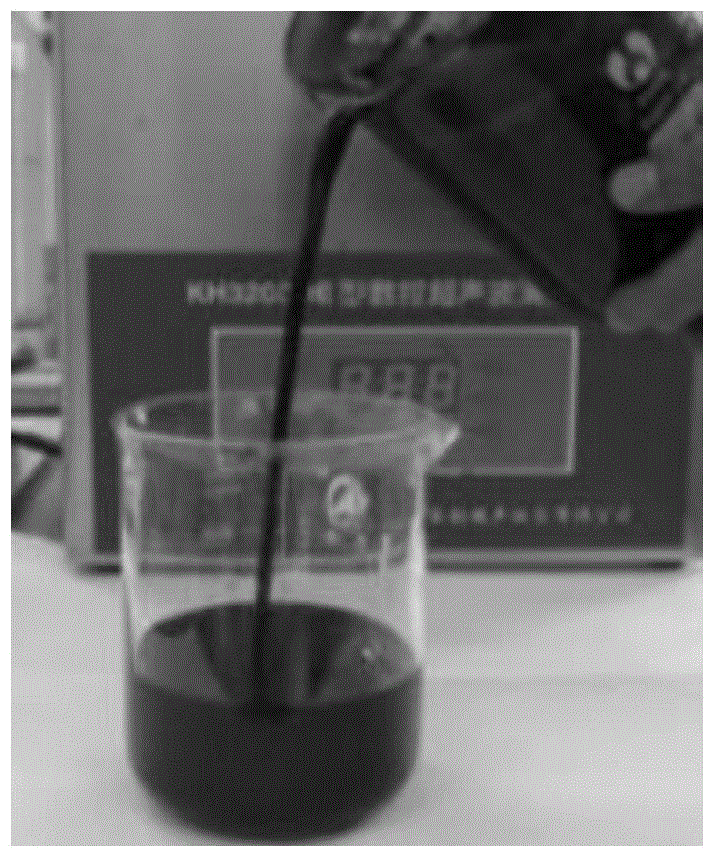

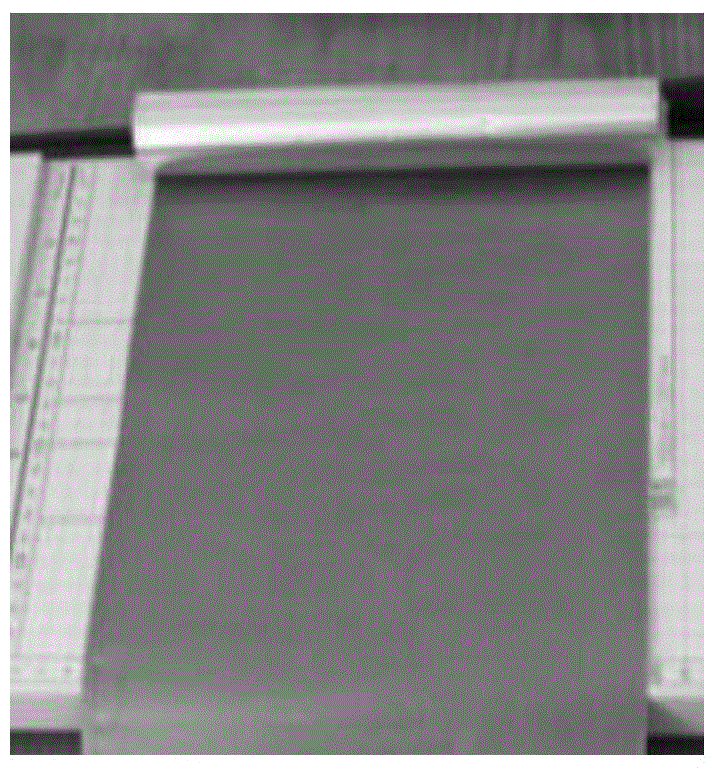

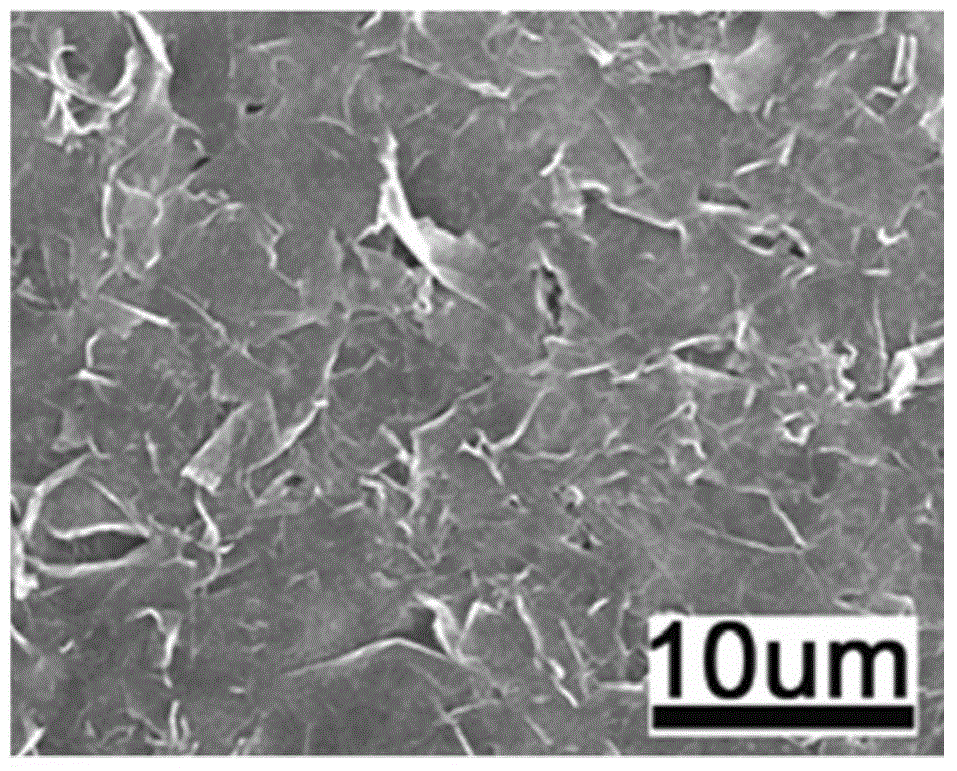

[0044] Add 2g of graphene powder prepared by intercalation exfoliation method into 100g of 0.2wt% allylamine aqueous solution (pH=3), and ultrasonically disperse for 30 minutes to obtain a uniform graphene dispersion. In the present embodiment, the concentration of graphene dispersion liquid is 2wt%, as attached figure 1 As shown, the stable dispersion time of the dispersion is greater than 180 days. Use the above dispersion to prepare a graphene film on the surface of aluminum foil by scraping method. After the film is formed, it is dried at 120°C for 10 hours to remove allylamine and obtain a graphene film attached to the surface of aluminum foil. figure 2 shown. The typical surface micromorphology of graphene film is shown in the attached image 3 As shown, it is shown as a dense film formed by overlapping graphene sheets, and the thickness of the graphene film in this embodiment is 1 μm.

Embodiment 2

[0046] Add 1g of graphene powder prepared by intercalation exfoliation method into 100g of 0.5wt% diallylamine ethanol solution (pH=3), and ultrasonically disperse for 30 minutes to obtain a uniform graphene dispersion. In this embodiment, the concentration of the graphene dispersion is 1 wt%, and the stable dispersion time of the dispersion is greater than 180 days. Use the above dispersion to prepare a graphene film on the surface of the polypropylene film by roll coating. After the film is formed, it is dried at 100°C for 5 hours to completely remove diallylamine and obtain graphene attached to the surface of the polypropylene film. film, if attached Figure 4 shown. Surface morphology and attachment of graphene films image 3 Similarly, the thickness of the graphene film in this embodiment is 3 μm.

Embodiment 3

[0048] Add 2g of graphene powder prepared by the intercalation exfoliation method to 100g of diethylenetriamine aqueous solution (pH=3) with a concentration of 1wt%, and disperse at a speed of 20,000 rpm for 30 minutes under high-speed shear to obtain a uniform Graphene slurry. In this embodiment, the concentration of the graphene slurry is 2wt%, and the stable dispersion time of the slurry is greater than 180 days. Using the above dispersion, a graphene film was prepared on the surface of a polyvinylidene fluoride (PVDF) filter membrane by continuous suction filtration to form a film. After film formation, it was dried at 120°C for 10 hours to completely remove diethylenetriamine. And after drying, the graphene film can be separated from the PVDF filter membrane to obtain an independent graphene film, as attached Figure 5 As shown, the thickness of the graphene film in this embodiment is 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com