High-conductivity paper pulp/carbon nanotube composite paper and preparation method thereof

A carbon nanotube composite and carbon nanotube technology is applied in the field of conductive paper to achieve the effects of excellent conductivity, high retention rate and no residual dispersant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

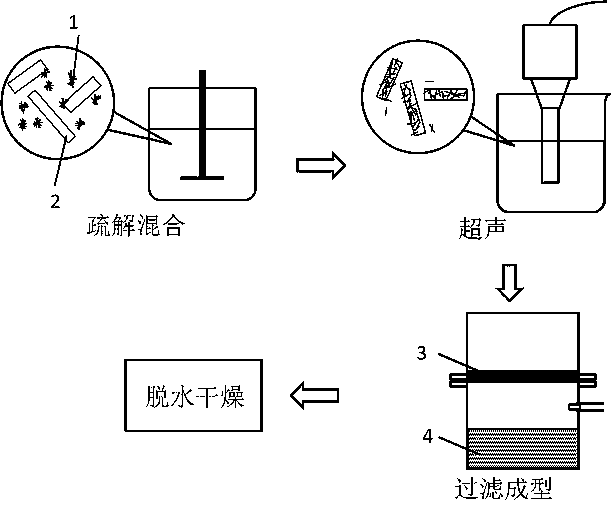

[0033] Such as figure 1 Shown is a schematic diagram of the process principle for preparing pulp / carbon nanotube composite paper. Cellulose / carbon nanotube composite paper was prepared by using cellulose pulp 2 and carbon nanotube 1. Put the cellulose pulp and carbon nanotubes in proportion to 2500 ml of water, and use a standard fiber disintegrator to disintegrate for 10 minutes. Then the mixed pulp suspension was diluted to a concentration of 0.2wt%, ultrasonically treated with an ultrasonic processor (20kHz, 2000W), and the ultrasonically treated mixed pulp suspension was poured into a Kaiser former to prepare wet paper web 3 , and then dried in a paper dryer.

[0034] In the first set of experiments, the mass of each sample will be kept at 12g (i.e. 80 g / m2), the content of carbon nanotubes (CNT) will be fixed at 20wt%, and different ultrasonic treatment times (i.e. different ultrasonic energy densities) will be prepared sequentially. composite paper, the specific ultr...

Embodiment 2

[0038] Aramid fiber / carbon nanotube composite paper was prepared by using aramid pulp and carbon nanotubes. The used aramid pulp includes aramid chopped fiber and aramid pulp, which are mixed in a mass ratio of 3:7. The specific operation process is the same as that of preparing and testing the cellulose / carbon nanotube composite paper in Example 1.

[0039] figure 2In Examples 1 and 2, resistivity curves of composite paper prepared through different ultrasonic energy density treatments. It can be seen from the figure that the conductivity of the nanocomposite paper without ultrasonic treatment is poor. The resistivity of the cellulose / CNT composite paper is 2.09Ω•cm, and the resistivity of the aramid fiber / CNT composite paper is 3.95Ω•cm. This is because the deflaking action can only disperse the pulp fibers, but cannot disperse the carbon nanotubes, so the carbon nanotubes cannot form a uniformly distributed conductive network in the pulp. After ultrasonic treatment, the...

Embodiment 3

[0048] In this example, it will be prepared by large-scale papermaking on a paper machine based on the process of Examples 1 and 2. Add cellulose pulp and carbon nanotubes into a hydropulper at a ratio of 4:1, add water, and turn on the hydropulper for disintegration. Then dilute the mixed pulp suspension to a concentration of 0.2%, use a pump to transport the ultrasonic reactor (20kHz, 12kW) to ultrasonically treat the mixed pulp, and transport the ultrasonically treated mixed pulp suspension to the inclined wire paper machine for making wet paper. The paper web is then dried in the drying section and wound on a winder (e.g. Figure 8 ).

[0049] The ultrasonic reactor is specifically a container with a power ultrasonic generating device inside, and the container includes an inlet and an outlet. In this embodiment, the mixed pulp suspension is continuously transported to the ultrasonic reactor through the inlet at a flow rate of 2 L per minute through the pump, and the ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com